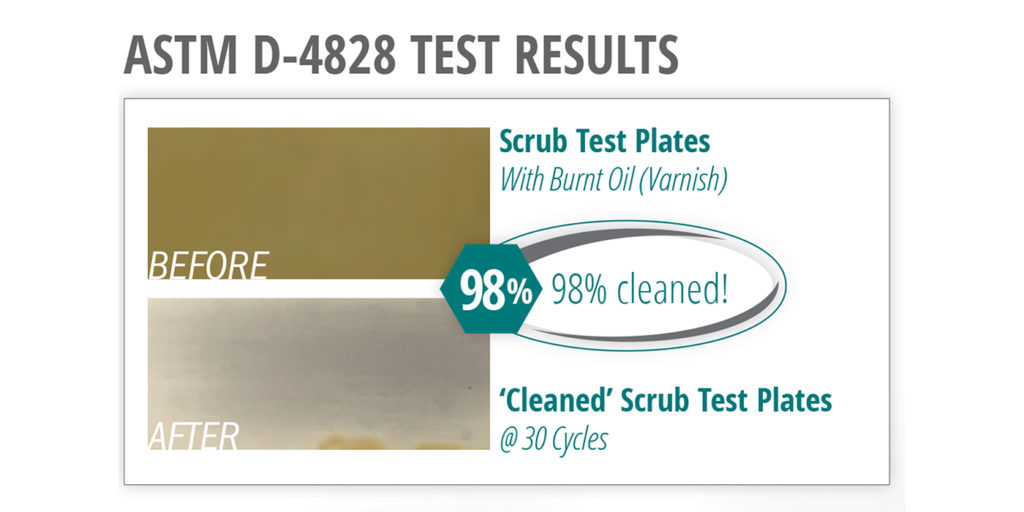

LSI Chemical has introduced NanoRestore736, a new oil additive developed for mineral, semi-synthetic or synthetic oils, that safely and effectively removes the varnish formed from burnt oil. Using the ASTM D-4828 scrub test, NanoRestore736 removed 98% of burnt oil byproduct and assisted in bringing deposits and additives back into solution.

Engineered from a Group V synthetic Ester with the addition of LSI’s proprietary synthetic cleaner and nano additive, this revolutionary new oil additive restores power and compression, reduces wear and the coefficient of friction while also lubricating to ensure all oil wetted components have a longer life span. NanoRestore736 is available now as an additive package or as an add-on to market ready products for a variety of industries and markets – automotive, agriculture, heavy-duty, industrial and marine. This product contains no harsh solvents and works over the lifespan of the oil.

In an ASTM G-133 laboratory test, Rotella T baseline oil treated with the recommended 5% NanoRestore736 treat ratio demonstrated a reduction in counterface wear from 0.0835 µm in the baseline oil down to 0.0314 µm.

LSI President, Todd Cawley, said, “Varnish occurs whenever there is a breakdown of engine oil from intense pressure and heat. The varnish, sludge and carbon buildup not only reduces power but can cause mechanical components to completely fail. This nano additive completely reverses the damage caused by stiction, restoring power and compression. If we are talking about an engine, say goodbye to rough starts or misfires. If it is a turbine, it will run more efficient – any mechanical equipment will benefit.”

For more information about LSI Chemical’s NanoRestore736, including the product’s technical data sheet, visit LSIchemical.com.