Article courtesy Engine Builder.

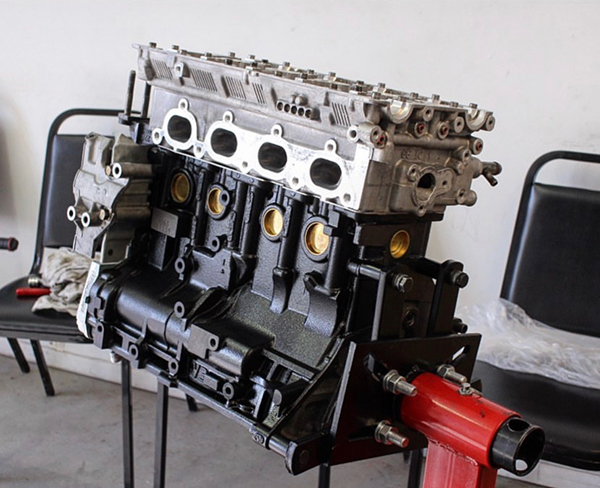

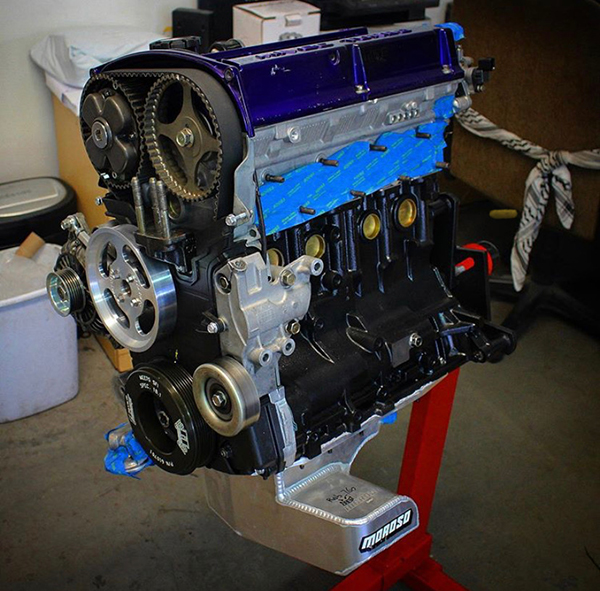

What Mitsubishi’s performance engines might lack in widespread availability compared to say Hondas, they make up for in motorsport heritage. Mitsubishi’s 4G63 engine was the powerplant under the hood of the World Rally Championship-winning Lancer Evolution. That engine, and its newer 4B11 variant, have since become favorites among many import car racers.

First introduced in the 1980 Lancer EX 2000 Turbo, the 4G63 engine has become a mainstay for performance-minded racers and engine builders alike. We caught up with Aaron Yaghoubian of Arlington Machine in Riverside, CA to get an idea of what it takes to make maximum horsepower with these engines.

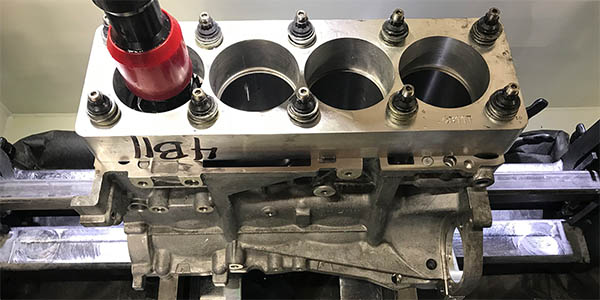

4G63

The 4G63 is a 2.0 L, 85mm bore and 88mm stroke engine, which came in both SOHC and DOHC iterations. Both versions were available in either naturally aspirated and turbocharged form. The DOHC version is found in various Mitsubishi models including the Lancer Evolution I-IX. Later versions also received Mitsubishi’s variable valve timing system, MIVEC.

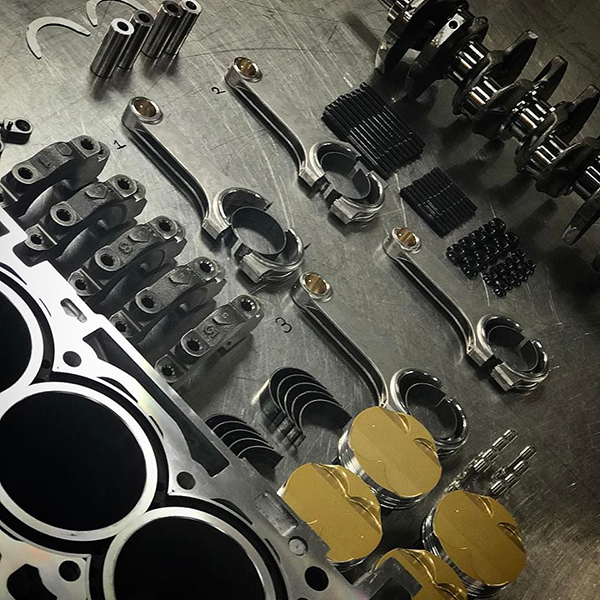

From 1990 to late April 1992, the engine came with thicker connecting rods and the use of six bolts to secure the flywheel to the crankshaft. In May 1992 to 2006, Evolution versions had lighter rods and use seven bolts to secure the flywheel to the crankshaft. They are referred to as the “six bolt” and “seven bolt” engines, respectively.

The final version of the 4G63 engine was found in the Lancer Evolution IX. It was equipped with Mitsubishi’s variable valve timing system, MIVEC, had a revised turbocharger, extended reach spark plugs, and two-piece rings.

“The most common and the most rebuilt ones are the 4G63, which would be the Evo 8 and 9s,” says Aaron Yaghoubian of Arlington Machine. “They have the Gen I, which is a six bolt, and a Gen II, which is a seven bolt. The Evo falls underneath the Gen II. Not too many people have the older stuff anymore.”

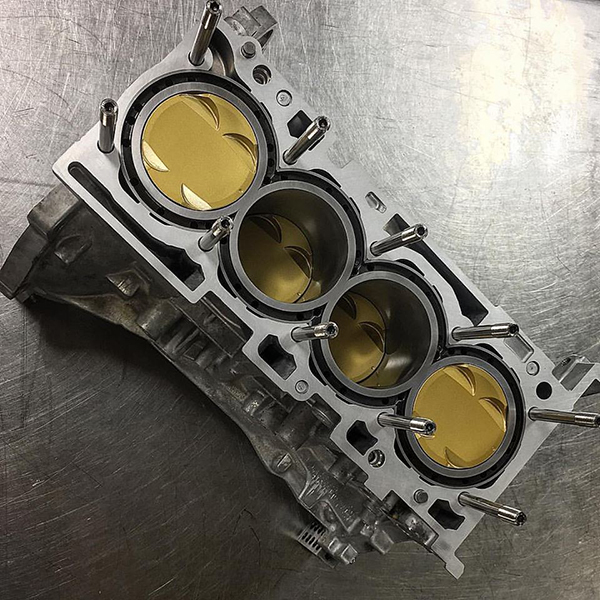

Since the 4G63 features a cast iron block, they can handle a lot of power on the factory sleeves. “We have full wet blocks seeing 1,000-plus horsepower on the factory block, obviously with doing main studs and head studs and little tricks here and there,” Yaghoubian says. “Compared to the 4B11, you don’t have the expense of $1,500 for sleeve install.”

While the 4G63 has a strong block and good factory sleeves, the engine does have several weak points when it comes to creating high horsepower. The engine’s balance shafts and its mains are two areas which Aaron says he makes sure to always check.

“We always delete the balance shafts so there’s fewer things in the engine that can fail,” he says. “The balance shaft belt, which is running off the crank, can break at high rpm and mess up your timing belt and throw your timing off. Since these are interference motors, you’ll end up hitting valves and bending valves.

“Another weak point on these engines are the mains because it is a cast iron girdle. A lot of people don’t think that’s an issue, but I tear them down every day and I see material fretting and material transfer from girdle to block. What ends up happening is under such high load and rpm, the girdle is actually moving around and trying to micro-weld itself to the block.

“One way we aide in fixing it is we torque the mains down a little tighter than most companies do. If you want to really take it to the next level, you can have billet main caps made and a custom girdle made for it. The billet material from the newer caps isn’t going to transfer material and it’s not going to walk around as much as a cast iron girdle.”

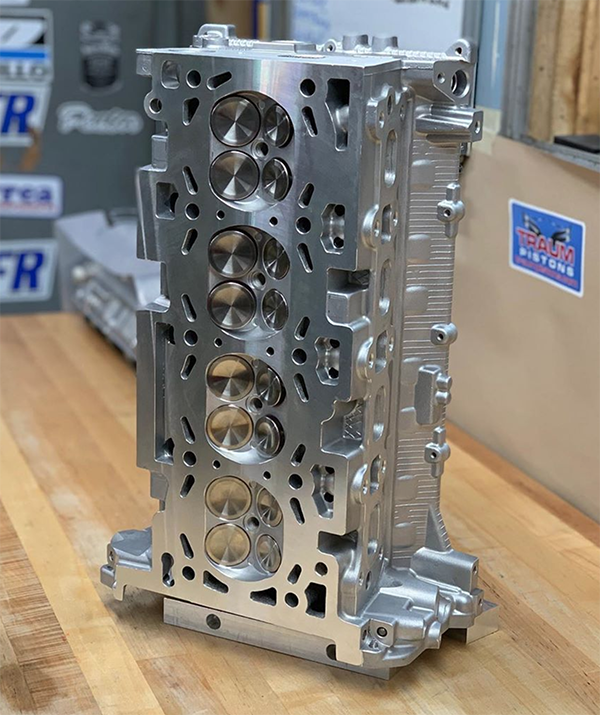

Looking at other weak points of the 4G63 when it comes to getting high horsepower, the cylinder head tends to lift, especially compared to the 4B11.

“On the 4G63, the threads on the head bolts aren’t even a half-inch down from the deck, so it’s not clamping everything together very well compared to a Honda or the 4B11 where the main studs are going almost all the way to the bottom of the cylinders,” Yaghoubian says. “On the 4G, everyone thinks the studs start stretching and the head starts lifting, but in reality, what’s actually happening is the pockets on the cylinder heads are aluminum, and they’re under such high pressure and load that the cylinder head is actually lifting up and the washers are getting sunken into the cylinder head.”

To combat this issue, Arlington Machine makes oversized washers that are 22%-23% bigger than the supplied washers from ARP. The shop also offers customers the option of a shoulder dowel.

“By putting in the shoulder dowels, that helps the material from not falling in and helps with not lifting the cylinder head,” he says. “To do that, the cylinder head has to come off and be machined specially for them.”

In addition to these upgrades, one of the easiest ones Arlington Machine always recommends to its 4G63 customers is to spring for the Kiggly HLA billet pressure regulator.

“It’s on the cylinder head and it will regulate a more constant oil flow to the top end and bottom end,” he says. “With the stock regulator, sometimes the bottom end will have too much oil flow, meaning your head is getting starved. Then, sometimes your head might be getting too much, meaning your bottom end is getting starved. The Kiggly HLA is a very inexpensive upgrade and there’s no tuning or anything needed – you just pop the valve cover off, take the stock one out and put that one on.”

When looking at the differences between the six bolt and seven bolt versions of the 4G63, there are a few, namely in regard to the crank.

“The Gen I has by far the strongest crank,” he says. “It comes with radiuses on the crank instead of undercuts on the Evo. Those undercuts on the crank are weak points for it to crack. I’d say 80% of stock Evo 8 and 9 cranks I pull out are cracked on number four. All of our cranks are magnafluxed and we check them all for cracks. Having a radius on the inside of a crank, where it goes from the journal to the counterweights, makes the crank 10-times stronger.”

When it comes to horsepower goals with the 4G63, it used to be that 500-600 horsepower was a lot of horsepower. Now, Yaghoubian says the average customer for street, drag or time attack applications is looking for 750-800 wheel horsepower. At the crank, they’re putting down close to 900-1,000 horsepower.

“With a stock block, people have made 1,200-1,300 hp with them,” he says. “However, those are just numbers. There are guys putting down crazy amounts of horsepower and they can’t run a good time at the track. I have some guys with lower horsepower cars running faster than 1,100-horsepower cars.”

4B11

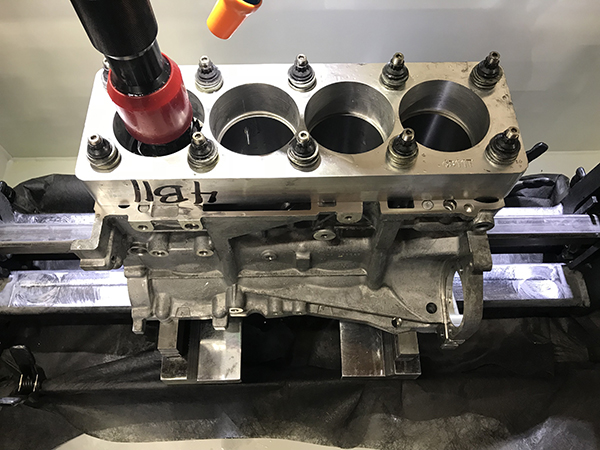

The other Mitsubishi engine Yaghoubian says he sees a lot of for performance applications is the 4B11, which is the more recent of the Evo engines. Mitsubishi drastically changed this engine family from the previous ones.

“The 4G has always been a cast iron block and when they went to the 4B11 they went to an aluminum block and an aluminum head – everything changed on it,” Yaghoubian says. “It went from a lifter-style head on the 4G to a solid bucket-style on the 4B11.”

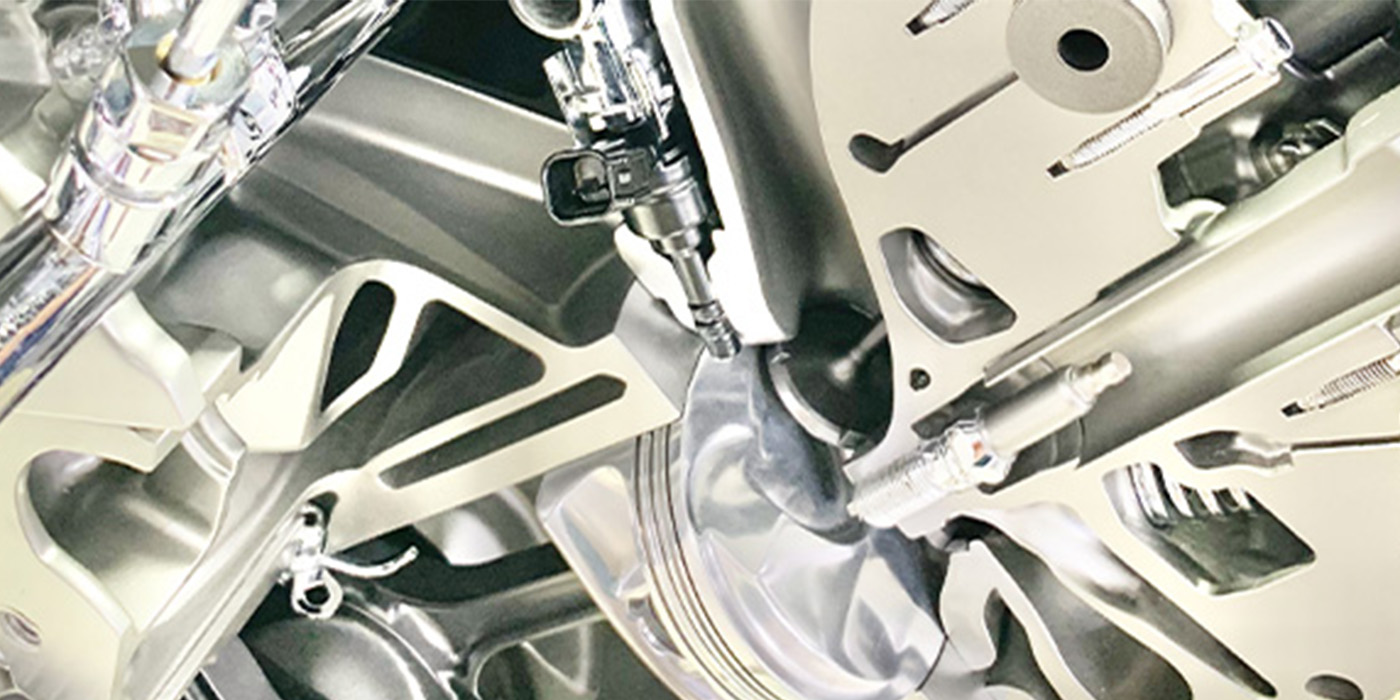

All engines developed within the 4B11 family have an aluminum cylinder block and head, four valves per cylinder, DOHC layouts, and MIVEC continuous variable valve timing. The 4B11 is a square engine featuring an 86mm bore and stroke. The new cylinder dimensions contribute to a free-revving character, linear power delivery and wide torque curve.

The engine weight has been reduced by 26 lbs. compared to the 4G63, even with the addition of a timing chain instead of a belt and a revised turbocharger offers up to 20-percent quicker response at lower engine speeds compared to the previous 4G63.

A semi-closed deck structure, an integrated ladder frame and four-bolt main bearing caps contribute to engine strength and durability. Unlike the 4G63, the 4B11 does not use a balance shaft. The semi-floating pistons of the 4G63 have been replaced with fully floating pistons for the 4B11. The engine also features an electronically controlled throttle, an isometric short port aluminum intake manifold, and the stainless-steel exhaust manifold is positioned at the rear of the engine.

The use of a direct-acting valvetrain eliminates the need of the roller rocker arm configuration previously used in the 4G63. The 4B11 features built-up hollow camshafts and its valve stem seals are integrated with the spring seats. The internal components of the 4B11 engine have also been reinforced to withstand high levels of boost.

“One of the weak points on the 4B11 would be the sleeves,” Yaghoubian says. “You can’t go super high horsepower with those sleeves. You’re only around 500-600 horsepower and even then it’s a guessing game as to when it’s going to blow up. I’ll replace them with LA Sleeves, Golden Eagle or Darton sleeves. Everything nowadays is all really good.

“Another weak point is the front cam cap. It goes from intake cam to exhaust cam across the head and a lot of times that cracks. AMS sells a billet cap and you have to put that on and machine it especially for that head.

“One of the other things I see is a lot of shops will replace cams and don’t recheck lash. We get it all the time that buckets and cams are prematurely messed up after 1,000-1,500 miles because the shops didn’t check lash correctly on it.”

Unlike with the 4G63, Yaghoubian says the 4B11 doesn’t have the same issues with the head lifting off the block and the head flows better for higher horsepower.

“With the solid bucket-style, the head does flow better,” he says. “It’s definitely better for higher horsepower because once you start getting crazy high boost, you need to start running very high seat pressures and open pressures on springs. You need an oiling system that can keep up to oil your lifters or the springs will start collapsing.”

While the 4B11 is capable of high horsepower numbers, many customers don’t typically get there due to the cost of having to re-sleeve the engine.

“A lot of them are around the 500-600-horsepower range, and I believe the reason is because of the sleeves,” he says. “Not everyone has an extra $1,500 to buy sleeves and install them, so they’re stuck on the stock sleeves. One of the nice things on a 4B11 is instead of a girdle on the mains, they went to five individual caps and four-bolt mains. Each one has four caps. That makes it a lot stronger and it’s a decent wide cap too with a good amount of surface area, so that makes the bottom end quite a bit stronger. We always stud the bottom ends with ARP studs.

“In an all-out build, someone could make 1,200+ horsepower. Once you do all that stuff to it, you’re just as strong as a 4G, if not stronger. Obviously, once you sleeve it, the sleeves are stronger than the sleeves that are in the 4G blocks to begin with.”

Conclusion

Whether a customer has a 4G63 or the 4B11 engine, they are both great options for many different performance applications. That being said, the 4G63 still tends to be the more popular option in the Mitsubishi/import market.

“We see way more 4Gs than 4B11s,” Yaghoubian says. “The 4B11s are newer, so not as many people are taking them apart. The 4Gs are a little bit older and they have higher mileage. The newer generation is buying the 4Gs up, the Evo 8 and 9, and they’re dumping money into them. Part of that is taking the engine out and redoing them.”