Article courtesy BRAKE & FRONT END.

Models

2013 -2019 Sentra

2013 – 2019 Versa Sedan

2014 -2019 Versa

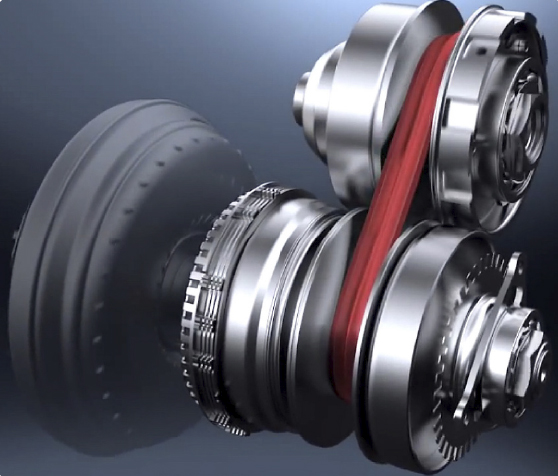

The Nissan XTRONIC CVT transmission can offer a dramatic improvement in fuel economy up to 10% or more compared to previous CVT transmissions for comparable vehicles. The Adaptive Shift Control (which adapts shifting patterns to match each driver’s style and the road) delivers responsive and powerful acceleration. The control system keep the engine from revving too fast at high speeds and minimize noise.

If the XTRONIC CVT has been serviced or parts like the valve body have been replaced, the clutch point relearn procedure needs be performed. If this procedure is not available on the scan tool, perform this manual procedure. Clear all stored trouble codes before beginning this procedure.

1.Start the engine and allow the transmission to warm to 122ºF (50ºC). Use a scan tool to verify the transmission temperature.

2. Turn AC off.

3. Move the shift selector to the Park position, turn ignition off, then wait 5 seconds.

4. Start the engine and allow it to idle for 5 seconds.

5. Turn the ignition off and wait 30 seconds.

6. Perform steps 4 and 5 two more times for a total of three cycles.

7. Restart the engine.

8. Allow the engine to idle for 30 seconds.

9. Move the shift selector to the “D” position.

10. Accelerate the vehicle from 0 mph (0 km/h) to 40 mph (65 km/h) at low throttle. Approximately 1/8 throttle.

11. Decelerate the vehicle to18 mph (30 km/h) or less without using the brakes.

12. Stop the vehicle and move the shift selector to the Park position.

13. Turn the ignition off and wait 5 seconds.

14. Restart the engine.

15. Perform steps 13 and 14 four times for a total of five cycles.

16. Move the shift selector to the “D” position.

17. Accelerate the vehicle from 0 mph (0 km/h) to 28 mph (45 km/h) at low throttle. Approximately 1/8 throttle.

18. Stop the vehicle and move the shift selector to the Park position.

19. Turn the ignition off and wait 5 seconds.

20. Restart the engine.

21. Perform steps 19 and 20 four times for a total of five cycles.

22. Drive the vehicle to ensure the smooth operation of the CVT transmission.

Note: Failure to perform this relearn procedure successfully will result in extremely harsh shifts.

Courtesy of ETE REMAN and ATSG.