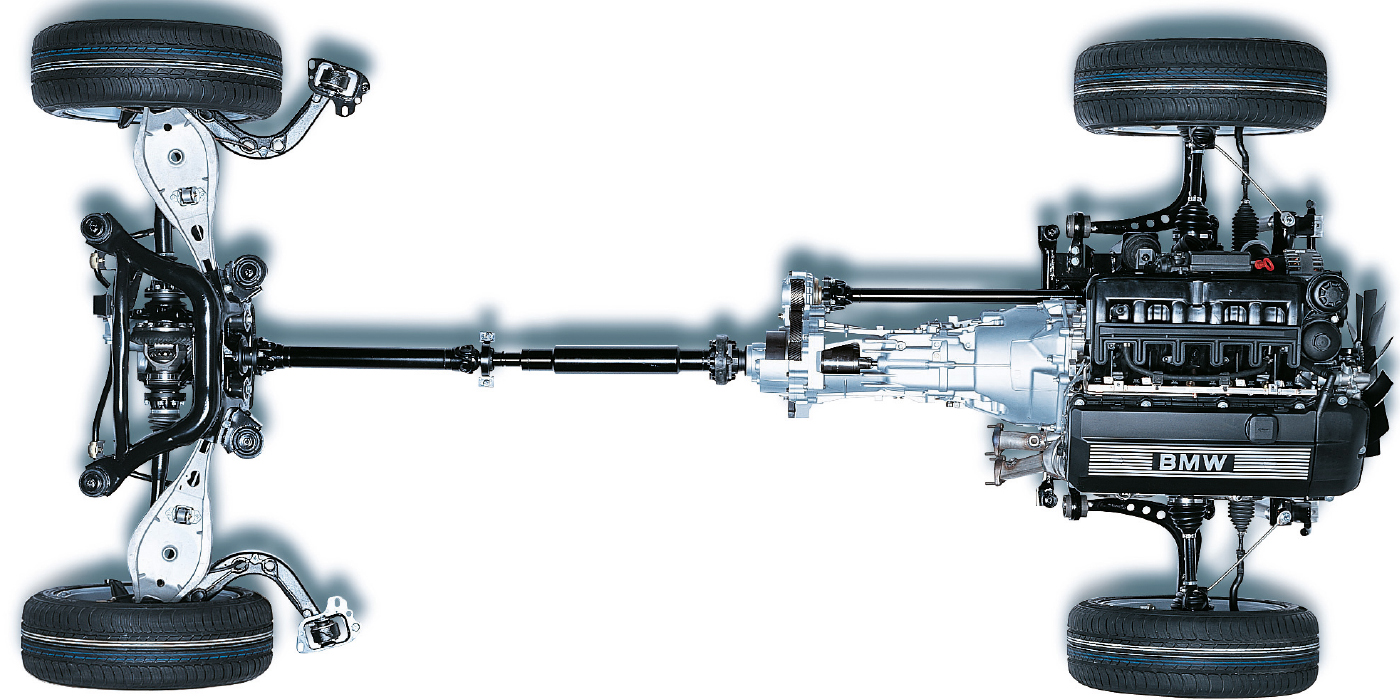

The 2004-2015 Titan was Nissan’s first attempt at a full-sized truck for the North American market. It could be ordered as a fleet truck or as a fully optioned 4×4.

The one problem area of the Titan was the rear axle. If you look at the online complaints concerning failures of the rear axle, the primary cause is the loss of the gear oil that lubricates the differential and wheel bearings. The typical path for the loss of the fluid are the seals at the ends of the axle tubes.

Bearing Replacement Options

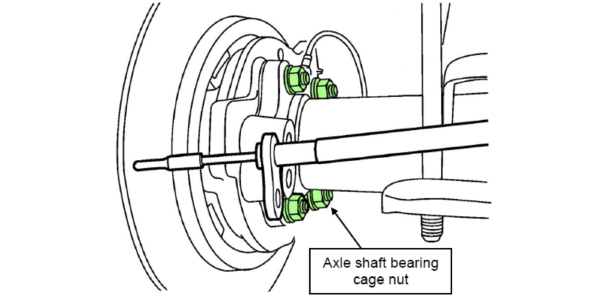

Before removing the axle shaft, remove the ABS sensor to reposition it out of the way. Failure to do so may result in damage to the sensor and cause the ABS sensor to become inoperative.

The good news is that you do not have a rear axle cover to remove or clip or bolts that retain the rear axle shafts. The axle shafts are splined on the inboard side and held in with the axle shaft bearing cage and torque member. But if you replace a wheel bearing, it is a good practice to service the fluid in the differential when replacing a rear wheel bearing.

The disassembly process is simple. First, remove the rear rotor and parking brake assembly from the backing plate. Next, remove the bearing cage nuts and lock washers. To pull the shaft, it might require a slide hammer.

The axle shaft bearing cup will probably stay in place in the axle shaft housing. Remove the race carefully with a bearing puller. Do not damage the inner surface of the axle shaft housing.

Replace the axle seals with the right sized seal driver.

The 2004-2008 models seem to have the rear axle seals that tend to fail and leak. Nissan issued TSB NTB10-32 in 2010 to address the problem. If the fluid in the rear differential gets too low, it can damage the ring gear and differential. When the bearing fails, it can cause damage to the surfaces on the shafts. The most common symptom is a whine between 50-70mph.

Once the axle shaft is off the vehicle, you have two options. You could remove the old bearing by removing the snap ring and breaking off the old retainer to install a new bearing. However, there is a chance that you can damage the axle shaft removing the retainer and races. The other option is to install a new axle shaft assembly that includes a new shaft with a bearing already installed. The latter option can make an easier repair that can improve your shop’s productivity.

Before finishing the job, make sure to inspect the breather on the axle. If the breather is blocked, it can cause the seals to fail.

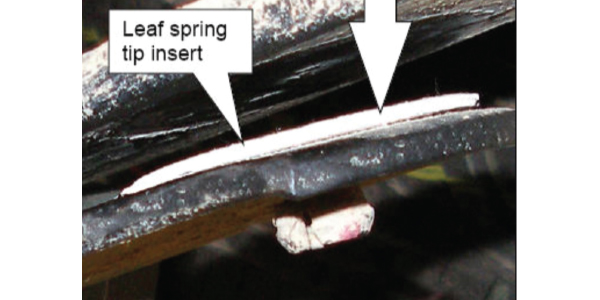

On higher-mileage Titans, the rear leaf springs may make some noise. There are two areas that can cause noise and vibration.

Rear Springs

On higher-mileage Titans, the rear leaf springs may make some noise. There are two areas that can cause noise and vibration. The first area is the pad between the axle and leaf spring. The other area that can cause noise is the spring pads between the ends of the springs. It is not uncommon for mud and debris to become lodged between the leaves and pads. Often just cleaning the area between the springs and replacing the pads will eliminate the noise.

For 2016, the Titan adopted the Dodge Ram platform. The reskinned Titan can even be ordered with a Cummins Diesel engine.

Article courtesy ImportCar.