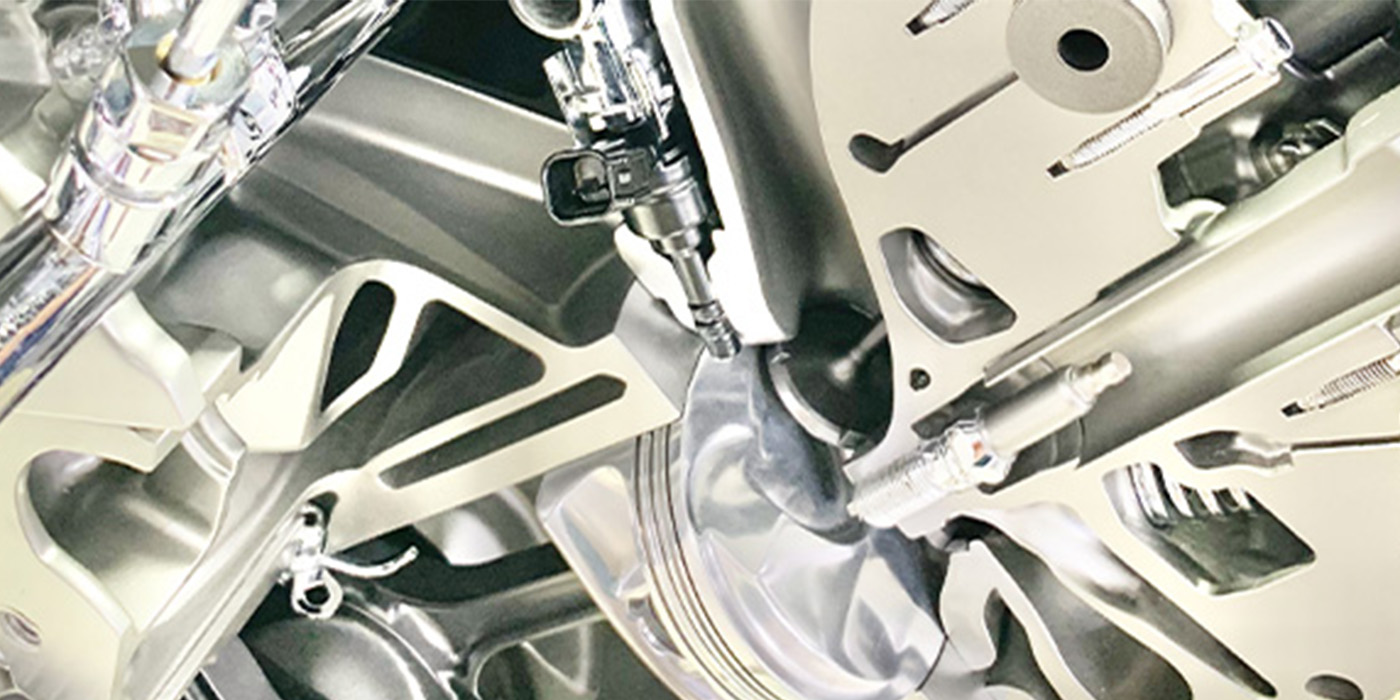

The PCV system helps to keep the pressure inside of the crankcase within a certain range. Blowby gasses are generated by the pistons moving up and down inside the cylinders. Automakers have come up with a number of solutions to control crankcase pressure. We’ve come a long way from the days of small, inexpensive PCV valves which were a regular maintenance item. Nowadays, PCV systems are far more complex, but they are also much better at controlling crankcase pressure.

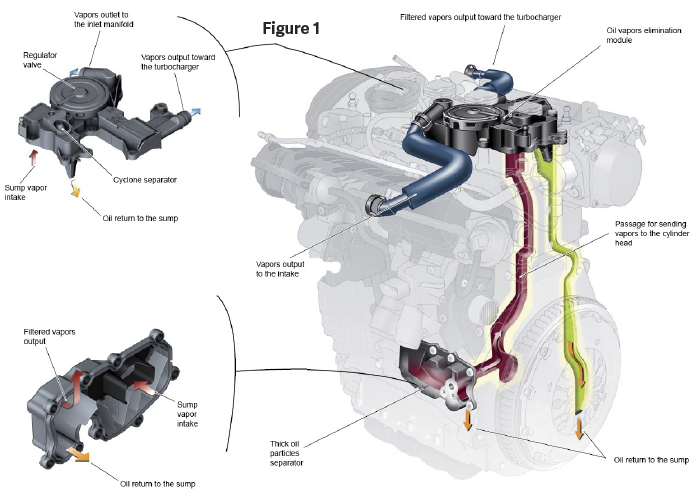

We know the job performed by the PCV system, but it can be connected to another important underhood system: the oil separator. The oil separator does what the name implies: it separates the oil droplets from the air inside the crankcase, then those droplets are able to drip down into the oil sump (Figure 1).

Look at the Big Picture

When it comes time to diagnose a potential issue with the PCV system, it’s very important to look at “the big picture.” To do this, we need to understand how the PCV system can affect other underhood systems. Remember that crankcase gasses are combustible, meaning that they will affect the way the engine runs. If a faulty PCV system allowed unmetered air into the combustion chamber, the oxygen sensors would detect a lean condition.

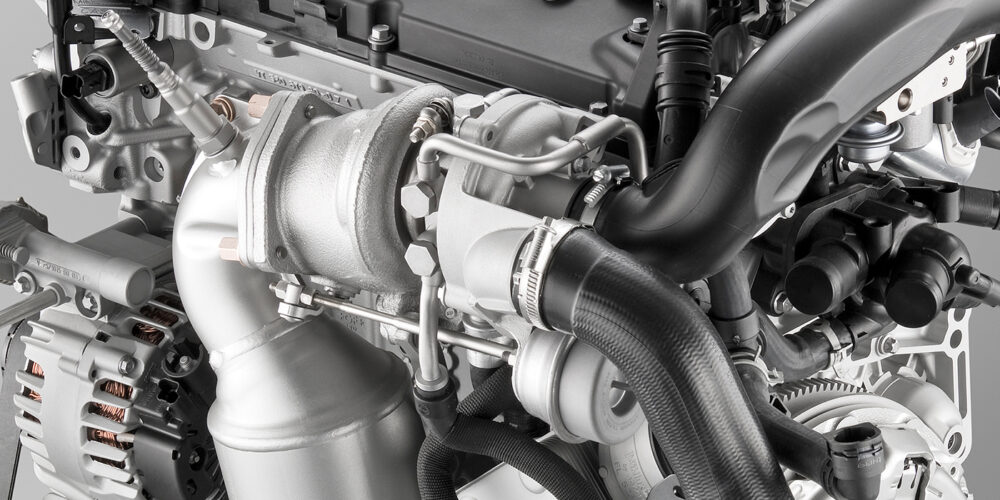

The PCV valve should allow for air to flow only from the crankcase into the engine at the appropriate time. On turbocharged engines, the intake air could be under boost. The PCV valve prevents that pressurized intake air from entering the crankcase. If the PCV fails, boost pressure could leak into the crankcase, resulting in reduced boost pressure and engine power. In some cases, gasses could be forced out the rear of the PCV and into the turbo. This is reason why some PCV failures will exhibit oil inside of the compressor housing, outlet pipe, and/or intercooler piping.

A customer may bring their vehicle to you with a complaint of an illuminated check engine light, reduced fuel economy, a strong smell of engine oil while the engine is running, etc. Any of these concerns could be tied to a faulty PCV system or component, diagnosis can still be tricky. If you were to scan the ECU for codes, the DTCs you see might not contain the term “PCV” anywhere in them. So, what sort of codes might you find in this scenario? There are a lot of DTCs to cover here, so we’re going to break these out into categories.

1: Air Leak/Lean Condition

- P0106: Manifold Absolute Pressure (MAP) Sensor Performance

- P0171: System Too Lean (Bank 1)

- P0174: System Too Lean (Bank 2)

- P2195: O2 Sensor Signal Biased/Stuck Lean – Bank 1, Sensor 1

- P2279: Intake Air System Leak

- P0300: Random Cylinder Misfire Detected

These codes all have a number of potential causes including, but not limited to, PCV system faults. If the PCV system is leaking, drawing in unmetered air from outside, the valve is stuck open, or the diaphragm is torn, you could see any of these DTCs stored in the ECU memory.

P0106 can be caused by an air flow restriction, vacuum leak, missing, restricted, or leaking exhaust components. I’ve seen P0171 or P0174 set due to an improperly seated oil dipstick or oil fill cap. A faulty PCV valve could cause a whistle, whine or low moaning noise.

Chevrolet discussed ways to diagnose this issue on its 1.4L turbo engines in TSB #19-NA-114. While the engine is running, use your finger to cover the breather port of the PCV diaphragm (circled in red in Figure 2). If the whistle noise goes away and/or the fuel trims are high, the PCV valve is faulty. Since the PCV valve is integrated into the camshaft cover, the entire assembly must be replaced, then the code can be cleared from the ECU.

2: PCV Heater

- P053A: Positive Crankcase Ventilation Heater Control Circuit/Open

- P053B: Positive Crankcase Ventilation Heater Control Circuit Low

- P053C: Positive Crankcase Ventilation Heater Control Circuit High

- P145E: PCV Heater Control B Circuit

- P1489: PCV Heater Control Circuit

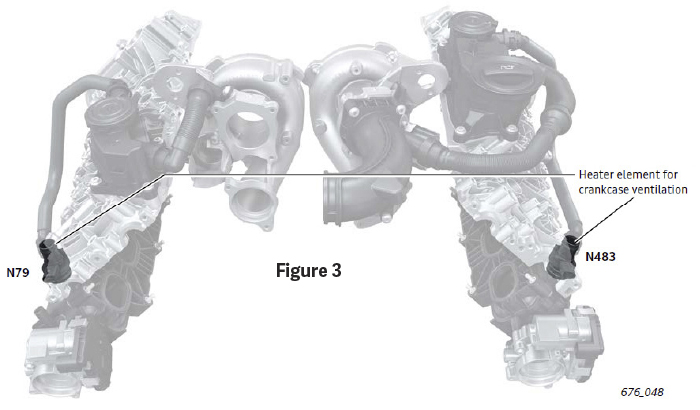

Heated PCV valves have been around for a while, and they can still be found under the hood of late-model vehicles (Figure 3). A small amount of moisture inside the crankcase can turn into ice once the engine cools down. If the ice were to form on the PCV valve, it would likely become stuck and unable to perform its job. Heated PCV valves combat this potential issue by applying 12V through a small internal heating element during cold starts.

In my experience, the most common cause for PCV heater-related codes would be install error. Someone disconnected the wiring harness and forgot to plug it back in. Occasionally, you may find that a rodent chewed through a harness, or that the heating element is simply worn out. Double check all harness connections, and confirm that the heater is receiving 12V power. Measure the resistance across the heater. If it shows open or out of limits, then the heater has failed and must be replaced.

3: Other

- P051B: Crankcase Pressure Sensor Circuit Range/Performance

- P0507: Idle Control System RPM: Higher Than Expected

- P051F: Positive Crankcase Ventilation Filter Restriction

- P1101: Intake Air Flow System Performance

In some applications, the ECU may monitor one or more crankcase pressure sensors. DTCs may be set if the ECU sees unexpectedly high or low crankcase pressure. This could be caused by a clogged or faulty PCV valve, or by a loose connection somewhere in the system.

Earlier on, we talked about the fact that blowby gasses are combustible, so if they find their way into the combustion chamber they will change the air-to-fuel ratio (AFR). A ruptured diaphragm or check valve inside the PCV system could allow these blowby gasses to enter the combustion chamber. If this happens at idle, the idle speed will increase. The ECU might notice this, and set DTCs related to idle air speed control or similar. Or it may something like P1101: Intake Air Flow System Performance.

The important thing to remember here is that underhood systems depend on one another, and the DTCs may not specifically call out the PCV system, even though it is in fact to blame for the condition. It’s our job as technicians to know how these systems interact, and how to diagnose what exactly is to blame for the customer complaint.