Timing chain guides are often the best indicators of the health of the timing chain, sprockets and the entire engine. Any abnormal noises or correlation codes need to be taken seriously. A timing chain guide is designed to keep the chain in tension so it will not flutter like a serpentine belt when the engine speed changes.

Abnormal wear patterns indicate a chain system problem like endplay in the crankshaft and camshaft or other sprockets. Wear patterns can also indicate if the tensioners and oil pressure are operating properly. Timing chain guides are designed to wear, but the guides are designed to last the engine’s life. If the guides wear prematurely, it is a sign that the path of the chain, lubricants or tensioners are not performing as they should.

To call some timing chain guides plastic is not accurate. The materials used by manufacturers are highly engineered resins and structural fibers. These materials are designed to withstand high temperatures and forces inside the engine. They are also engineered to withstand engine oil and harmful vapors created by blowby inside the combustion chamber. The engineered materials are also designed to endure thousands of heat cycles.

When a timing chain guide breaks or cracks, it indicates a lack of maintenance, high miles, or a failed component. For some applications, a failed tensioner will cause timing chain slap that can damage the guide. Other mechanical items can hasten a timing chain failure, like multiple overheating incidents or blocked oil passages in the top end of the engine.

So, why aren’t all timing chain guides made of metal? The simple answer is noise. If a guide was made of stamped or cast metal, there is a possibility that it would cause sound to be transmitted from the engine to the vehicle. Even if you have a cast metal guide, chances are it will have plastic inserts that contact the chain.

Tensioners

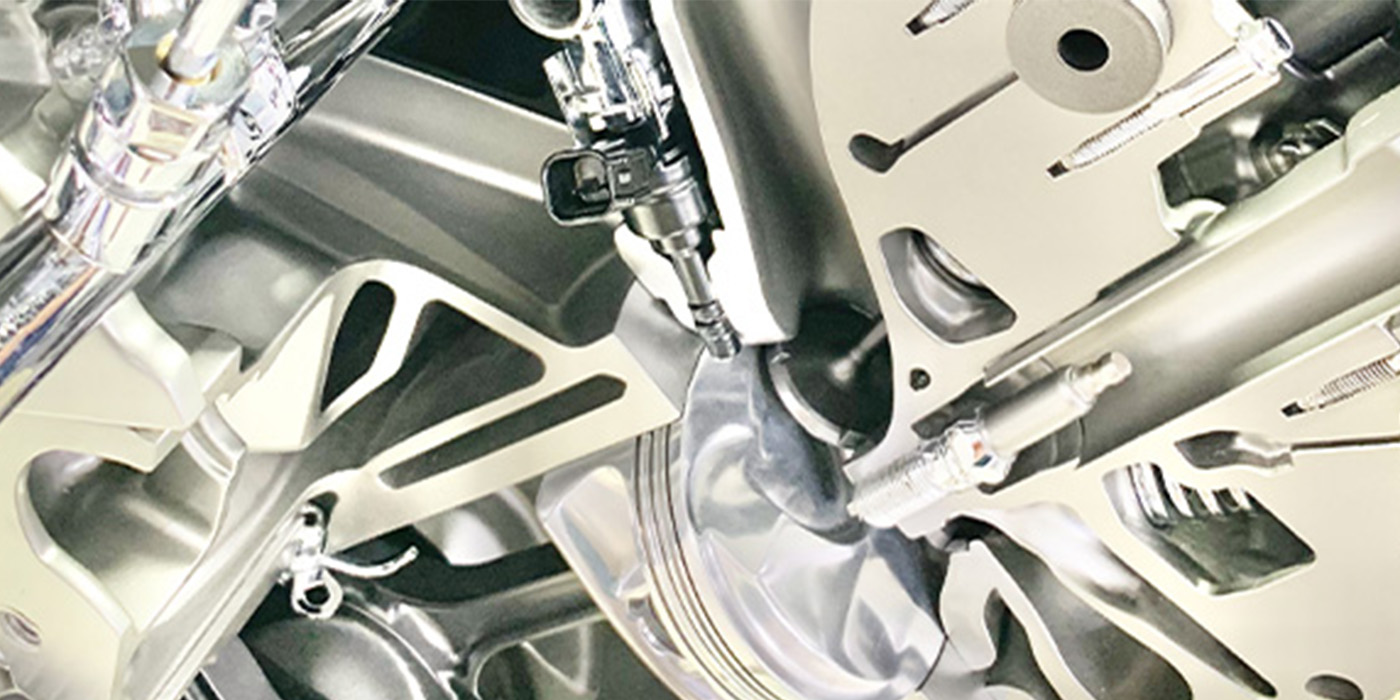

The majority of timing chain tensioners use oil pressure to take up slack in the chain. Like the guides, a tensioner will age prematurely as old oil degrades the seals and clogs the oil passages.

The typical tensioner assembly consists of a housing, spring and ratcheting plunger. The plunger is locked into the housing to prevent the accidental release of the spring before or during installation.

Timing chain stretch is not the stretching of the timing chain; it is an elongation of the timing chain caused by wear to the chain’s components. The most common cause of timing chain stretch is lack of maintenance and regular oil changes.

Worn-out oil can no longer lubricate the chain and will cause the rollers and links to wear against each other. In addition, as the chain runs around the gears of the camshafts and crankshaft, the movement between the rollers and links causes wear and elongation.

As the timing chain wears, this can change the timing of the camshaft and crankshaft. The change in timing is sensed by the camshaft and crankshaft position sensors. This can cause codes that indicate the correlation or synchronization problem with the engine position sensors.

If the driver ignores the check engine light, the timing chain will eventually elongate to the point that the engine may have a significant loss of power due to a lack of compression. Sometimes, a worn timing chain may cause the engine to jump time a few teeth. If this happens on a multi-cam engine, it may appear to be a dead miss on multiple cylinders. The bad oil can also damage the tensioner, which makes the possibility of the engine skipping time or a catastrophic failure even greater.

If you are replacing a timing chain or chains, it is also critical to inspect and, in some cases, replace components that tension the chain and variable valve timing actuators. The actuators are powered by the same oil that damaged the timing chain. Inside a variable valve timing actuator are finely machine surfaces and seals that can are easily damaged by worn out or the wrong type of oil. In some cases, it is cheap insurance to replace the actuators while you are replacing the timing chain and guides to ensure that the customer gets the full value of the labor time.

If you are replacing a timing chain, always replace the guides and don’t leave them behind in the kit. Also, ensure you are returning the timing system to like-new condition.