Manufacturers like CVT transmissions for ATVs and UTVs because they are cheap and simple automatic transmissions. The CVT often gets a bad rap from users because the transmission doesn’t deliver the power how the user wants. Like stock suspension settings, the manufacturer is shooting for a middle-of-the-road approach that will function fairly well under a wide variety of circumstances or feel good with a quick test ride. Often this results in a set up that is optimized for quick acceleration or economy, but may have poor initial engagement, slow back shifting, poor engine braking or a poorly matched shift curve to power output.

The good news is many CVT systems can be tuned. The service manual will usually include information on CVT tuning based on altitude similar to carburetor jetting changes. At a minimum the service manual will include an altitude chart with spring and weight options to optimize performance at specific altitudes. Polaris service manuals will go beyond this with additional information on how the springs and weights can be changed to make desired changes to the CVT performance. The OEMs are aware of the tunable nature of CVTs and provide information and factory parts to optimize the base vehicle to its operating environment.

Beyond factory CVT tuning options, popular models have excellent aftermarket support it this area. Snowmobile folks have been tuning these things for decades. Companies like Starting Line Products are applying its long-time snow machine tuning knowledge to ATVs/UTVs. Not only does the company have a wide variety of CVT components, but it also has the knowledge and ability to customize kits to fit modified vehicles and meet specific performance goals.

1. If a CVT isn’t performing as desired, the first step needs to be an inspection of the existing components. Changing springs and weights will have you working in circles if core components are in poor condition or out of adjustment. Check component alignment and clearances according to the service manual. Make sure the belt, pulley faces, bushings, bearings, springs, rollers and weights are in good shape and installed correctly to start with. New parts shouldn’t be ordered until the current setup is documented.

2. The CVT system has two pulleys or clutches – a drive and driven clutch. Both have features that can be changed to alter CVT performance. The drive clutch has a spring and weights. The driven clutch has a spring and helix shape. While there is some overlap, generally the drive clutch tuning should address initial belt engagement and engine rpm, and the driven clutch tuning should address shifting characteristics, especially downshifting and belt squeeze.

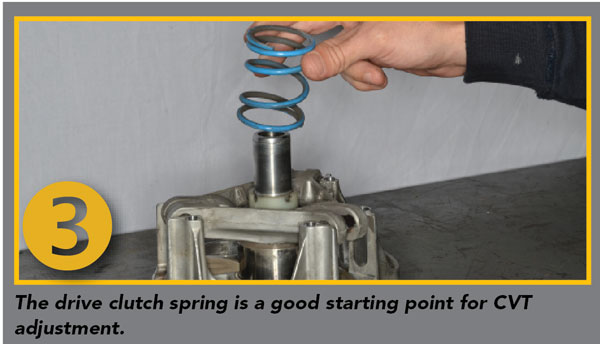

3. The drive clutch spring controls engagement rpm (initial preload) and peak shift engine rpm (final compression). When tuning pay attention to the two spring rates: the spring at idle compression (usually 2.5 inches) and the spring at full compression (usually 1.25 or 1.19 inches). A 120/300 spring would engage about the same as a 120/320 spring, but have a lower peak rpm than the 320 spring. A 120/310 spring and a 160/310 spring would have about the same peak rpm, but the 120 would engage earlier than the 160 spring. The spring also plays a role in controlling the rate at which the CVT changes ratio, specifically how much engine rpm is required to upshift. Changing the spring should be the first step in adjusting clutch engagement and shifting performance.

4. The shift weights work in combination with the driven clutch spring to open and close the drive clutch. The shift weights can be changed in shape and weight to alter the clutch engagement and shifting performance (both up and down). Heavier weights will allow the engine to turn less rpm to upshift and lighter weights will require more engine rpm to upshift. When the drive clutch spring and weights are in proper balance the maximum desired rpm (peak power) should be reached promptly after belt engagement at wide open throttle. Note, changing the weights can alter belt-to-sheave clearance, clutch balance, engagement and shifting characteristics.

Adjusting the drive clutch components is just one area where CVT can be tuned. Flip through to Powersports Tech Tips in November when we provide even more on driven clutch components and further CVT tuning information.

Article adapted from Cyclepedia Press LLC article in Motorcycle & Powersports News.

Cyclepedia Press LLC authors powersports service manuals, a specification database and training modules to help technicians efficiently service ATVs, motorcycles, scooters and side-by-sides. Each month Cyclepedia examines real life shop scenarios with recommended tech tips for handling the

problems encountered. For more information about Cyclepedia manuals and professional products, visit www.cyclepedia.com.