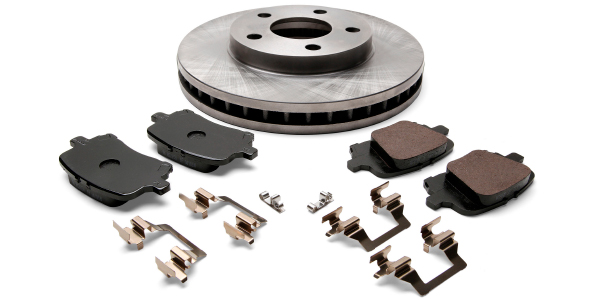

Brake hardware is often a second thought when it comes to replacing a set of brake pads. I can remember not that long ago when it was rare that any new hardware was included with the replacement brake pads. Typically, techs were forced to reuse old hardware or, in some extreme cases, either go without or make something else fit. Now, you probably expect, at minimum, new abutment clips to be included. But there are other hardware items you should also consider while ordering new brake pads.

CALIPER GUIDE PINS

If the caliper is not free to move, the culprit might be bent or binding mounting pins. Even if guide pins are not damaged, swollen or hardened guide seals or lack of lubrication may cause the caliper to bind, resulting in uneven pad wear. Always inspect all mounting surfaces and hardware for corrosion, wear or misalignment. Replace all mounting hardware and install a replacement caliper using the proper caliper lubricant.

ANTI-RATTLE CLIPS

Heating and cooling cycles can weaken springs and anti-rattle clips. Weak parts can result in excessive caliper/pad movement or binding, causing noise and other related problems. This can lead to uneven and premature pad wear, rotor wear and pulling. On some floating calipers, the most neglected piece of hardware is the clip in the bridge.

CALIPER GUIDE

PIN BOOTS

Most floating brake calipers use a rubber or plastic insulator or shim around the mounting bolts of the caliper. This sleeve of soft material loses resiliency over its lifetime. This is hastened by the high-temperature environment of the brakes.

As materials wear, instead of being round they become flattened by the torque from the brakes into an oval shape that can cause excessive caliper movement. This can cause noise like rattles and thumps even if the brakes are not applied.

Always inspect and replace, if necessary, any dust boots or grommets that protect caliper bolts or slides. If the soft parts look OK, clean out all the old lubricant and replace with new lubricant.

Unlike steel, soft parts like rubber are sensitive to certain chemicals. Choosing the right lubricant for these parts is critical to ensuring the integrity of the part.

If the caliper boots fail to make a seal with the caliper bracket and bolt, water can be sucked into the cavity as the bracket contracts and cools.

SHIMS

Insulating the brake pad from the caliper can be done two ways. The first option is to go the “chemical” route with sprays or paste coatings. This type of noise solution involves coating the back of the pad prior to installation. The coating serves as a layer between the pad and caliper. If your shop uses any of these products, make sure to follow all manufacturer directions on where to apply and what the curing times are. Not following the directions can mean a comeback.

The second solution is a physical shim that is a sandwich of materials staked to the back of the pad. One drawback to shims can be “shim migration” or shifting that can negate its insulating abilities. To address these concerns, automakers and aftermarket parts suppliers are developing an attachment system to alleviate this problem.

Some automakers stamp notches and posts that index and stake the shim on the pad. Certain manufacturers of shims use pressure-sensitive adhesives to secure the shim to the backing plate. But over time, moisture and heat can destroy the adhesive. One new design to secure the shim to pads are clips that clamp on to the sides of the backing plate. These clips reduce the tendency of the shim to shift or fall out during the life of the brake linings.

CALIPER BRACKETS

Caliper brackets can become corroded when the caliper is exposed to road de-icing salt. Corrosion on the lands and slides should be removed with a wire brush or wheel. If the corrosion is not removed, it can cause the pads to bind even if a stainless-steel abutment clip is on top of it. Also, clean the sealing surfaces around the caliper guide pin. If the surface is not smooth, the boot can’t make a good seal.

New caliper brackets are available separately and some remanufacturers include brackets as part of the caliper assembly. Just make sure you return the old bracket to get full credit for the core.

PAD SEPARATORS

More and more OEMs are including springs that are designed to push the pad away from the rotor after the piston retracts. These clips can increase fuel economy while eliminating brake noise.

These springs/clips can be difficult to install, but they always should be re-installed. Some aftermarket brake companies are offering a solution that can be used on the caliper. The clips are designed to push the pad away from the rotor. This can keep the brakes cooler, reduce noise and extend the life of the pad.

The clips fit between the pads and rotor and push the pads away from the rotor. These clips have more spring, while not preventing the movement of the caliper’s piston. They also have the potential to reduce pulsation complaints.