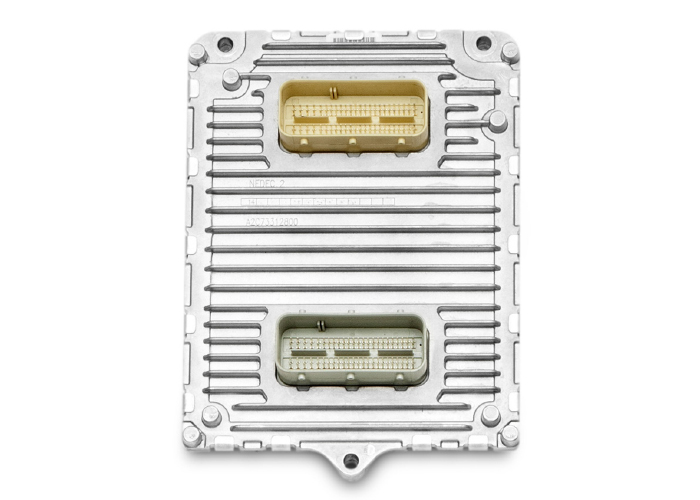

According to NHTSA, during the first two months of 2020, more than 100 Technical Service Bulletins (TSBs) were issued in which the fix was updated software. This number does not include updates that do not require a TSB to be issued. Many of these software updates address issues concerning drivetrain control modules.

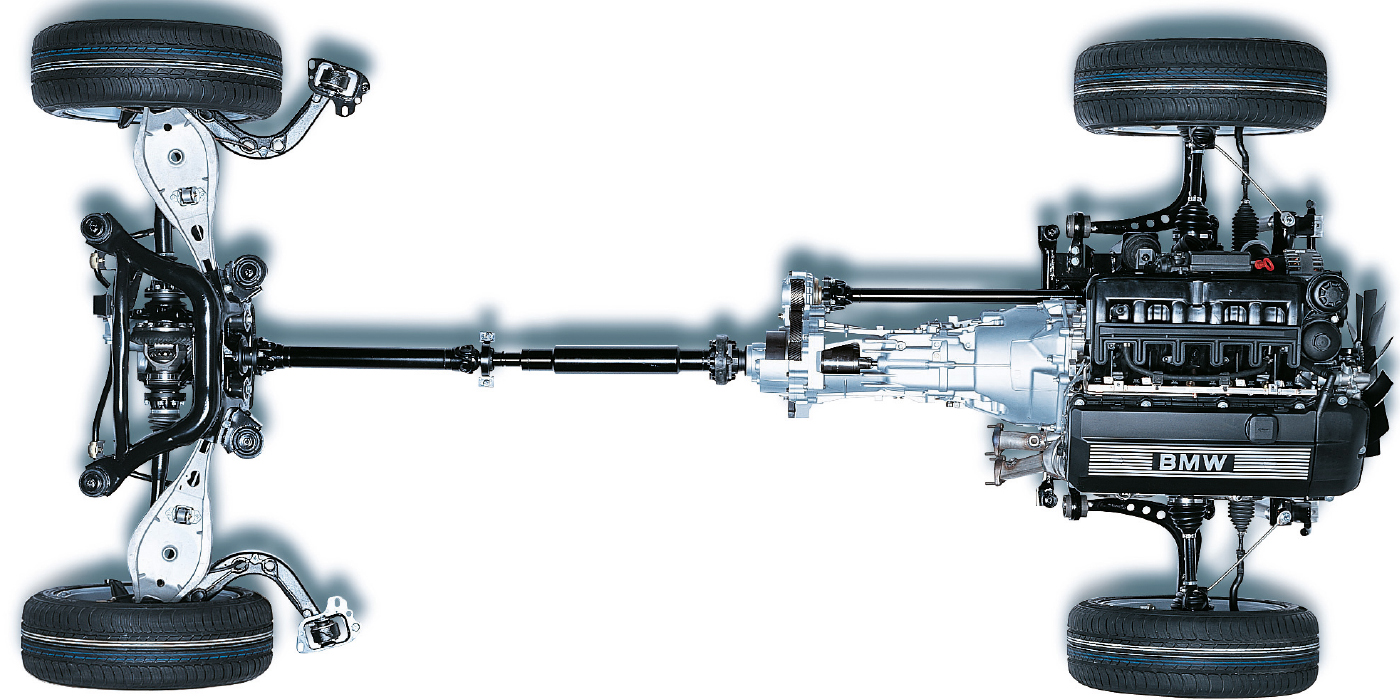

The majority of these drivetrain updates improve operation, shift quality and the longevity of the internal components inside the transmission – and it is not uncommon to see these updates for vehicles that are more than four years old. Another trend is TSBs in which the first instruction is to check if the vehicle has the latest software in a transmission control module.

If your shop is planning to perform drivetrain diagnostics, service and replacement, you need to be able to reflash or reprogram transmission and engine control modules. If not, you can quickly see the profitability in a transmission replacement evaporate. It’s understandable to have a lot of questions and fears about reprogramming.

Why can’t a replacement transmission be shipped to my shop with the latest calibration, and already programmed for the vehicle?

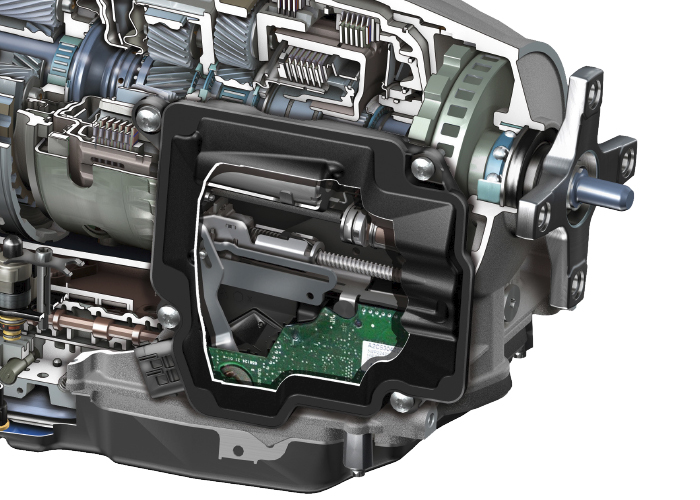

The transmission is connected to multiple modules on the vehicle. It communicates with the engine and even the ABS system on a high-speed network. The protocols or language of the network uses OEM and vehicle-specific data like the VIN and vehicle configuration for options. This data or firmware is written specifically for the vehicle by the OEM. In some cases, it is possible to “clone” a module, but it can take time to ship the module to and from the service facility.

A growing trend with some OEMs is to classify the transmission module as a security part. To be able to program a transmission module, it might require National Automotive Task Force (NATF) vehicle security provider credentials.

I work on all makes and models – what is the most economical way to tool up to service all of our customers’ vehicles?

Before you purchase a computer, it is a good idea to select how you plan to connect to the vehicle. Most of all, you need to understand what the interface can and can’t do.

SAE J2534-1 is the protocol for reflashing and reprogramming emissions and engine module calibrations through the generic OBDII port. The SAE, EPA and automakers collaborated to comply with the mandate that emissions calibrations can be updated.

If you need to program a non-emissions module on some vehicles, you might need a vehicle interface that can communicate using SAE J2534-2. But, these two communication protocols are not enough for every vehicle or every module. Automakers will also use other communication protocols for other modules and systems on the vehicle.

If you specialize in one make, you might be able to get away with just a USB cable with the OBDII connector on one end. These cables can be very effective for vehicles from one manufacturer because they are hardwired for the OEM’s software. Unfortunately, suppliers do not make cables for every manufacturer.

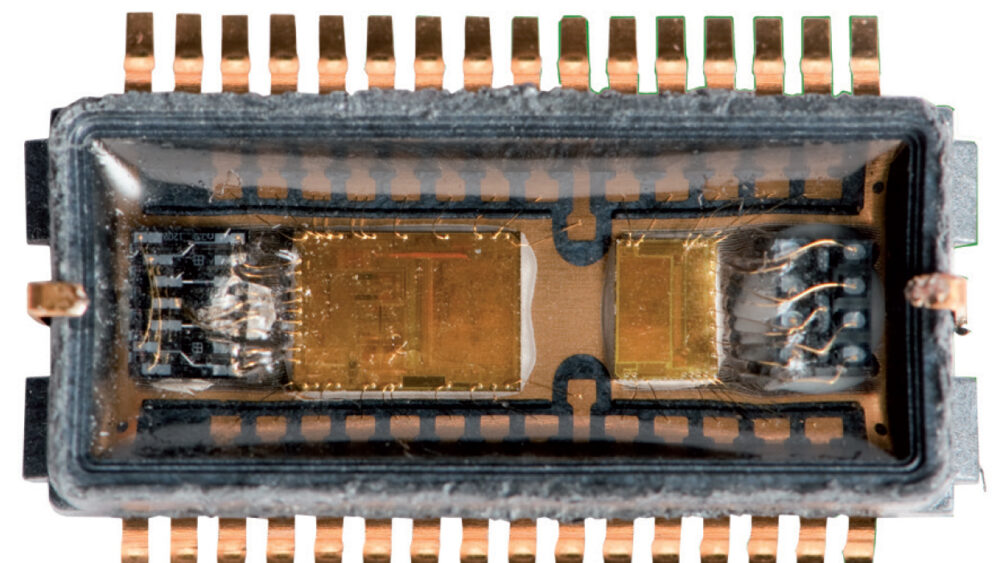

The next solution is a J-Box. This still connects to a USB port on the computer and the OBDII connector, but in between is an electronics-filled box. The guts of the box switch the pins in the OBDII connector and translate the information from the vehicle and computer. These can handle multiple makes and protocols. With either cable or J-Box, it is critical to look at the coverage and compatibility with the vehicles coming frequently to your shop.

However, each OEM is still allowed to approve or certify if a cable or J-Box will work with its software and website. You may find that a cable or J-Box will work one day, but the next day there could be problems. When these problems occur, you can find support out there from the OEM, tool manufacturer and even online groups of technicians.