Article courtesy ENGINE BUILDER magazine.

The modern-day restoration has taken on a different meaning than restorations of the past. There will always be the purist who restores a car to its original, off-the-showroom state, and in many cases, this is a monumental undertaking when every date code, every flaw and every last detail from firewall markings to paint overspray is replicated.

Those that perform restorations to this extreme detail certainly earn my admiration and respect, but unfortunately, a lot of those cars only see mileage up and down the ramps of an enclosed trailer.

Enter the restomod, a term we all know well. Whether you use the term or not, the fact is, the majority of modern restorations include some type of modification as an upgrade to modern vehicle systems. By the time we hit the ‘70s, most cars had power brakes with discs in the front, they rode nice, had air conditioning and cruise control as options, and for the most part they handled well, taking in account that the straight line was still all that mattered for a lot of us.

If our world was still like it was in the ‘70s, the restomod wouldn’t be a thing. But it’s not. The number of cars on the road back then was sparse compared to today, and new cars stop and handle far better than anything from a few decades back. Regardless of how an old car handles compared to others during its heyday, driving one today requires a much higher level of caution. The majority of the driving public doesn’t care, or frankly realize, you might not have the same features they do. They will cut in front of you and slam on the brakes with no thought that you may not be able to stop or maneuver as well as them.

There are more potholes, more orange cones, more debris and more car parts that litter the roads these days and just way too many reasons that vehicles on the highway need to be able to stop and handle to today’s standards. When you consider the creature comforts like air conditioning and power windows, plus the drastic driveability and economy advancements due to fuel injection and electronic engine controls, for most people to enjoy an old vehicle on a regular basis, changes need to be made.

For shops that specialize in this type of work, the approach with their customers has also evolved along with the modern vehicle restoration. The first step in the process begins with a conversation. Chris Wright, owner of Pro Car Associates in Akron, OH, is no stranger to the restomod process. “We offer total engine systems and solutions” is their motto.

“It’s about getting the customer to understand they can come to us for the whole thing,” Wright says. “Restorations really become a project management side of the business. The customer just wants what he wants and so he doesn’t need to necessarily understand all the backend stuff. We just have to get it done.”

Since there are so many options available in a modern vehicle restoration, it is more important than ever to determine what the customer is looking for and what their expectations are. Different engines, transmissions, suspensions, chassis work, brakes, electronics and convenience features can vary the cost from four-digits to six-digits, so the goals have to be clear.

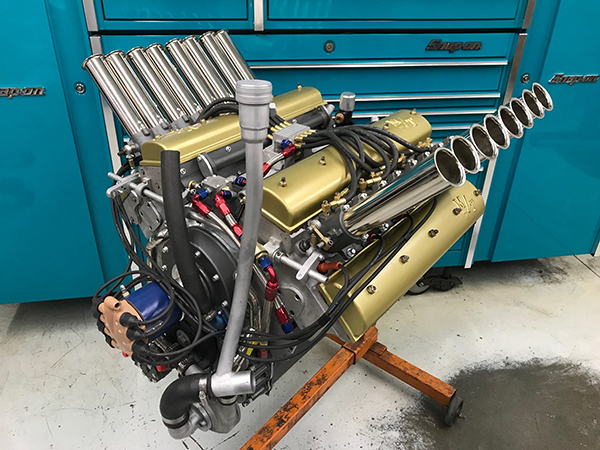

“People have learned over time that they can come to us for anything powertrain related, from the engine all the way to the rear end and doing the EFI conversion, tuning, engine management systems, powertrain management systems, and more,” he says. “There’s all kinds of options available. It’s understanding what their needs are and what their budget can handle. Depending on what they’re looking to do, it can be anywhere from $4,000 to $50,000 in a heartbeat.”

Once the work is in the door, it becomes a matter of organization and planning to perform all of the work in a timely and efficient manner, and one of the biggest factors is having employees that can perform the work.

“It’s a balancing act of finding the right skill sets in the right people and keeping them in their strong skillsets and what they enjoy doing as well,” Wright says. “You want passionate people that love their jobs so at the end of the day it makes them really happy and they will work hard at it.”

The same line of thinking applies to a modern-day restoration as it does when building any type of race car. Any modifications or departure from a completely stock automobile can affect all other vehicle systems, so the job must be considered from the standpoint of the whole vehicle as opposed to any single component.

Project management begins with someone who understands the entire vehicle build and the modifications that will be required. What engine and transmission is going to be used? What is the suspension set up and differential gearing? A project manager must be able to see the big picture and understand the major contributors and factors that affect vehicle design.

In addition to the major design factors, you cannot overlook electrical wiring, fuel lines, brake lines and routing of coolant lines, as much of this can be drastically different from the original.

Your shop’s space and its equipment also play a big part when tackling full restoration work as the entire vehicle needs to be in the shop, and large sections of it will be in different areas at different times.

“All the different types of work you do require different areas like the fabrication area, the machining area, general work, assembly work, and engine build areas,” he says. “When I go into a shop and they talk about building all these bad-ass cars, the first thing I look for is where’s the fabrication area and what kind of equipment they’re dealing with, because that tells me right away if they’re the real deal or they’re farming out a lot of stuff and they’re just a speed shop bolting stuff on.”

You will also need to consider all of the additional equipment that is required such as cleaning equipment, chemicals, blasting cabinets, saws, a lathe, mill, sanders, drills or grinders. All of this is in addition to your standard hand tools and there can be even more depending on how much you are getting into and how much fabrication you are doing such as a brake to bend metal, benders for making lines and forming large tubing, rollers for strengthening metal and many different specialty tools.

Even if the tools, equipment and facility space is covered, you have to consider the most critical factor that drives it all: cash flow. “The hard thing about projects is the cash flow; the revenue stream coming in,” Wright says. “The in and out quick turnaround work is usually the better money in this business because you do more of that and your cash flow is really good every week. In project work, your cash flow can be more of a monthly thing, so you really have to have a good process in place for customers to understand how your billing is going to work. A project could take one or two years, so you have to have realistic discussions with the customer on expectations and timeline. If you have the space, you can have projects that can sit while you perform quicker jobs to maintain cashflow. If you don’t have the space, you cannot afford too many projects.”

If you don’t have the space or all of the equipment, that isn’t to say you can’t get involved in these types of restorations or restomods. Many companies work together and coordinate to lend their particular skills to a project. Once the design and major modifications of a car are planned, any major fabrication must be performed first.

“We do partner with key people depending on the level of work that is needed, such as body shops or custom chassis shops,” Wright says. “We do a lot of custom work ourselves, but when it gets into crazy chassis work and roll cage work, we work with a partner. We’ll manage the whole project but work with our partners so we can still do these types of complete builds.”

Getting into restoration work and restomods requires a lot of planning, a lot of equipment, and proper project management, but it sure can be a lot of fun and also one of the most rewarding things you do. Most of all, it could keep your business afloat in tough times.

“To have those different revenue streams is crucial,” Wright says. “When you become a great engine builder, you can start adding other aspects to your business. It just takes time, knowledge, research, and figuring it out. You can do a lot of different things, quite honestly, but it’s a matter of how passionate and devoted you are to your profession if you want to be really good at it.

“What we notice is when the economy tanks, our general auto repair side goes away, but all the performance stuff stays up and people are doing more of their projects. You have to be open to doing a lot of different things, but doing it successfully is the key. Don’t do what you’re not comfortable with.”