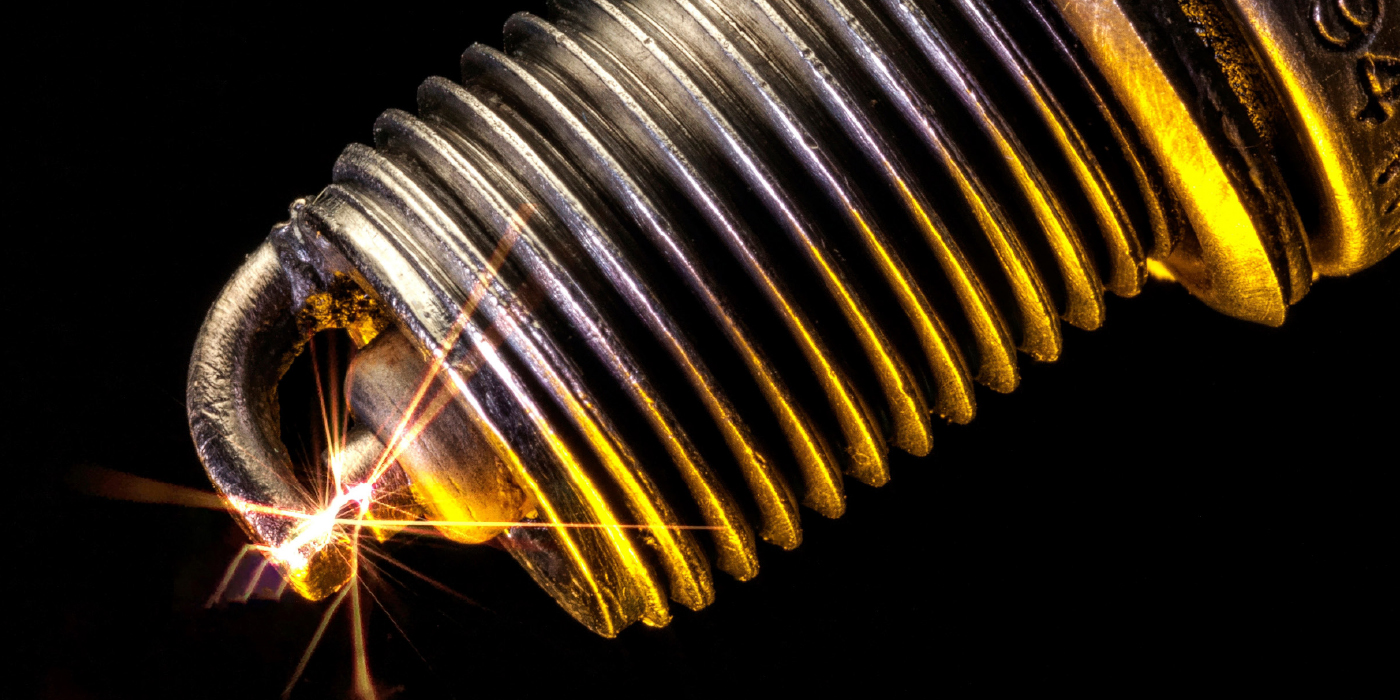

Have you seen an uptick in misfire codes or engines running rough at your shop in April or October? You might think it is the spark plugs or even ignition coils. However, the real cause could be seasonal fuel blends.

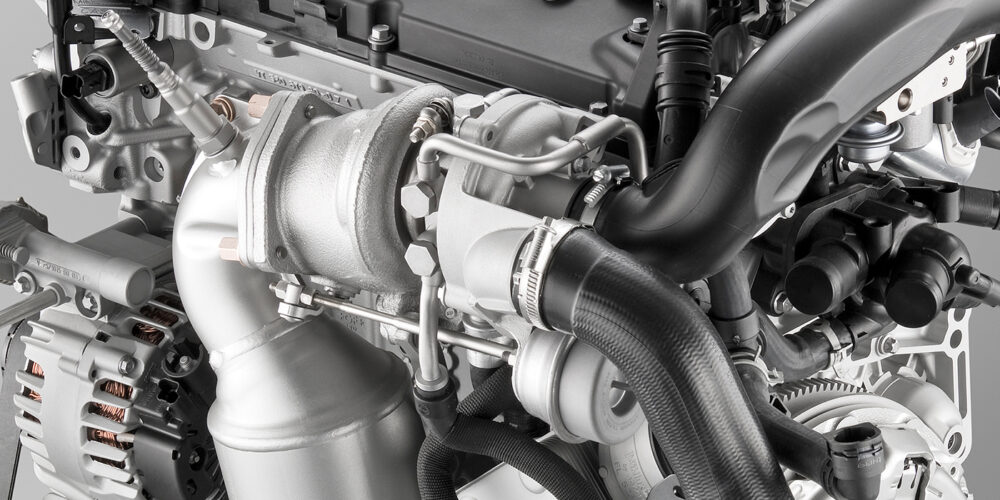

In some areas of the country, when the gasoline blends change from winter to summer or summer to winter, some turbocharged and/or direct injection engines have problems.

The cause of the misfires is the temperature fuel evaporates, otherwise known as the volatility.

Gas is gas, right? No.

Summer blends are designed to evaporate at higher temperatures to prevent evaporative emissions. During winter, they change the mix to be more volatile at lower temperatures for improved cold starts and lower start-up emissions. Gasoline distributors will change the formulations typically in late September and early April. But, it is difficult to predict the weather.

A warm day in October or a cold day in April can cause issues with these fuels and generate random or specific cylinder misfire codes. Also, other codes can help you determine if it is a fuel or ignition issue. Or the problem could be what some gasoline formulators call “overhang” when the supply of winter or summer lasts longer than expected.

The fuel’s volatility can directly impact how the flame front propagates inside the cylinder under certain conditions like cold starts and high loads at specific engine speeds. One of the most common symptoms described is misfires when the vehicle is traveling at freeway speeds when the engine is between 2,000 and 3,000 rpm.

Freeze frame information can give you valuable insights when a misfire occurs. Look at engine speed, vehicle speed and coolant temperature. Some vehicles will include the ambient temperature in the freeze frame information.

Another code set could be P0316 for misfires detected during the first 1,000 revolutions. This can be caused by the lack of fuel in the rail or the volatility of the fuel at low or high temperatures. Again, look at the freeze frame information. Code P0316 is typically set in open-loop operation and before the oxygen or air-fuel ratio sensor is at operating temperatures. It is also a sign that the current conditions do not match the long-term fuel trims. These factors could include poor-quality fuel for the conditions.

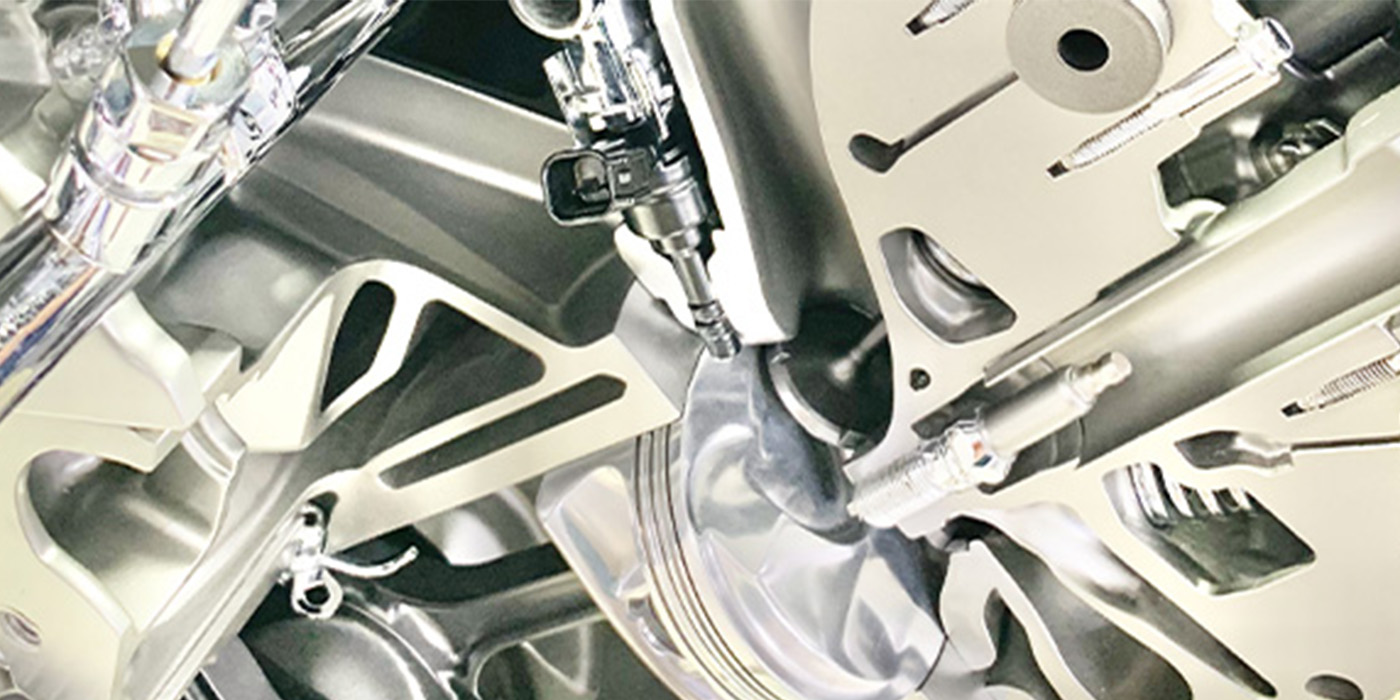

Winter blend fuels in warm weather can cause extended crank times because the higher underhood temperatures can evaporate the fuel from the rail and injectors. If the engine has direct injection, the fuel can evaporate in the low side of the injection system, and it might take extra time to prime. Some OEMs might set a code for extended crank time.

What is the cure? Simple, Maintenance. Today’s import nameplate turbocharged and direct-injected engines operate on a very fine line between maximum efficiency and a misfire. Any changes to the inputs like air, fuel or spark can cause a misfire and codes.

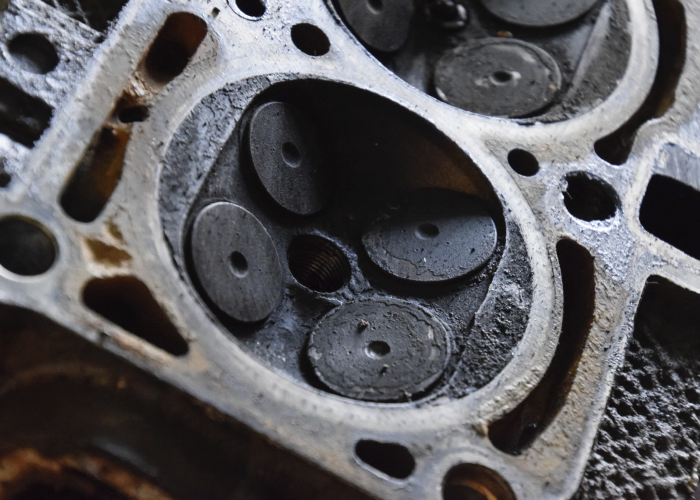

Let’s say the coil is degraded and the secondary can’t generate enough current to cause a spark in the cylinder, it could cause a misfire. The same is true for a worn spark plug. Poor-quality fuel just exacerbates the condition of the ignition system. Carbon deposits and even clogged fuel injectors can also be contributing factors.

If you get a car in with misfires and other misfire-related codes at the start of winter or the beginning of summer, it could be an issue with the gasoline in the tank. But, before you blame the gas, take a look at the codes and take a look at the maintenance performed.