Secondary air injection was added to vehicles in the late 1960s to combat air pollution after it was discovered that tailpipe emissions were causing smog in major cities like Los Angeles. The first systems were called “smog” systems, and the extra supply of air came from a belt-driven pump that was tagged with the name “smog pump.” Smog systems are much more complicated these days because government regulations are more stringent than they were in the ’60s.

Today, we have vehicles with three-way catalytic converters and wideband O2 sensors that switch off the secondary air injection after about a minute and a half when the converters come up to full operating temperature.

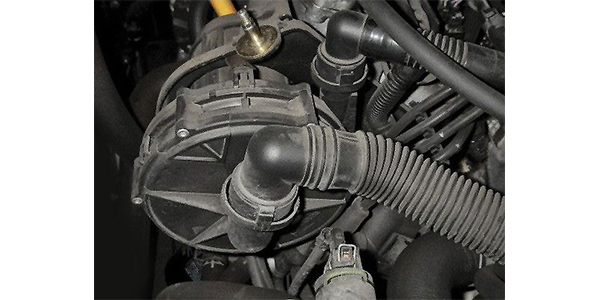

Secondary air injection can be supplied actively from an electric air pump or passively from pulse pressure in the exhaust system. In a passive/pulse system, air is drawn in when a valve opens from vacuum created through exhaust flow. In an active system, air is blown from an electric pump, which allows for better control. But, a failing air pump or valve can cause a DTC to come on for incorrect airflow. The engine may idle rough or lack power as a result.

The secondary air injection pump can also fail due to problems with the electrical motor. Sometimes, the pumps, after frequent exposure to cold or wet weather, will corrode and freeze up on the inside, causing a failure. The internal parts of the air pump may also wear out over time.

On some VWs, the air pump is set to come on between 59 and 95 degrees of engine coolant temperature. The system uses the O2 sensor to determine if it needs to activate. The sensors will report a lean bias when the system is on. The O2 data stream should change with the system on. If it doesn’t, the sensor may need to be replaced.

Electric secondary air pumps are found on many European models and a few domestic vehicles, as well. These pumps don’t require engine power to run and shut off once the catalytic converters are warmed up. However, the electric motors can, and do, fail. Many of these pumps are placed in areas where they are exposed to a nasty environment that can be wet and icy, which is no good for electric motors, as the conditions may cause corrosion, and the pump will stop working altogether.

The following are a couple of cases of secondary air injection failure and how they were diagnosed:

1. A 2013 Chevy Equinox 2.4L sets a P0411 code for Incorrect Flow, Secondary Air Injection. The system was tested, checking the valves and pump operation. Testing revealed the check valve was not functioning correctly. The check valve and the system were checked again for proper operation. A week later, the car is back with the same P0411 code. The valves and pump were tested and were in working order. The next option was to remove the passages to the head to make sure they were clear. Carbon buildup was found blocking off two of the four passages in the cylinder head, which was the underlying issue.

2. A Toyota TSB says that secondary air pump failure can occur due to debris getting into the pump. The secondary air injection pump has been reported to fail and come apart internally, which can plug up the lines with debris. The scenario involved a 2006 Tundra 4.7L with a P2445 stored and was in limp mode. After applying power to the pump directly, a significant draw was discovered. The technician pulsed power to the pump and it freed up. The pump was removed and the housing was disassembled. The fan was not damaged, but the pump was full of debris, which was cleaned out and reassembled.

While the government may prefer vehicles with zero emissions, at this point it is not yet possible. No internal combustion engine is 100 percent efficient, but we are getting closer to the goal with gasoline direct injection and other computer controls that can time the combustion for the most complete fuel burn. Until there’s a way to heat up the catalytic converters or remove them, secondary air injection is going to be around for a while.

Article courtesy Underhood Service.