What is a coil?

From the beginning of the internal combustion engine, several different ignition systems have been used to create a high-energy spark. The most popular system, and the one that’s in use today, is a step-up coil.

A coil is nothing more than a transformer, and like any transformer, it has two separate coils of wire inside, commonly referred to as windings that wrap around a core of magnetic material. In newer transformers, the core is made from a series of plates — usually a ferrous-type metal — laminated together.

The first coil of wire is called the primary; the second coil of wire is called the secondary. The primary winding has a large diameter with fewer windings, which allows it to have a low resistance to current flow. The secondary is a much smaller diameter wire with a greater number of windings.

The primary and secondary windings of an automotive coil typically have a 1:100 winding ratio. In other words, for every 1 winding of the primary, the secondary has 100 windings. The primary winding for a standard automotive coil usually has about 1 to 4 ohms of resistance; the secondary winding usually has about 8,000 to 16,000 ohms of resistance. The primary and the secondary are electromagnetically coupled, so anything that affects one winding is mirrored in the other winding.

Inductance

The physics are the same no matter the size of the coil. A current flows through a winding, which is used to create a magnetic field. This magnetic field buildup is called inductance. The magnetic field is proportional to the current — the larger the current, the larger the magnetic inductance. This current flowing through the primary coil winding allows the energy to build that magnetic field.

As the magnetic field builds, it moves across the primary and secondary windings, which induces voltage in both the primary and secondary winding. However, the effect of this induction is different within the two windings. As the magnetic field builds and moves across the secondary windings, an electromotive force is induced, which in turn creates the high voltage.

Capacitance

Between the coil windings is what’s called capacitance. Capacitance is when two conductors are separated by space and current is allowed to flow through the conductor. Electrical potential is built up between the two conductors, and the size of the conductors and the distance between these two conductors determines the capacitance. This allows the capacitance between the coil turns to build electrical energy.

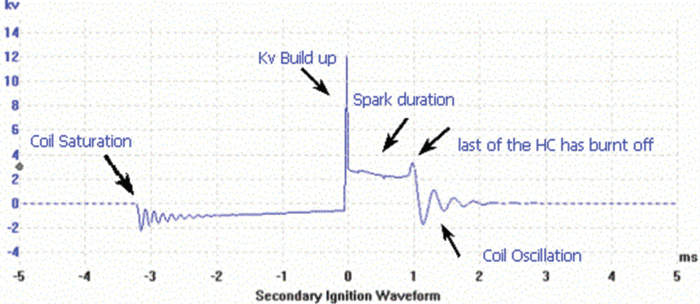

Saturation

Once the current rises in the primary windings to a point that it basically can’t hold any more, the magnetic field is fully built up and completely surrounds the secondary windings. This is referred to as the saturation point. The larger the current, the larger the magnetic lines of force. Likewise, the smaller the current, the smaller the magnetic lines of force.

Dwell

A coil takes a finite amount of time to build up this charge. That’s the dwell time, normally defined as the degree of rotation of the camshaft during which the input signal is shunted to ground. Too little dwell and the coil won’t have time to charge up fully; too much dwell and the coil loses some of its charge and causes a weak spark. Hesitation, low power, misfiring, pinging and a number of other conditions are symptoms of an incorrect dwell setting.

Back in the day of points and condensers, checking the dwell was part of an all-around tune up. Since dwell is measured by the camshaft rotation, and the camshaft runs at one-half the speed of the crankshaft, for every two degrees that the dwell was off, the actual engine’s timing would be off by one degree. Because of the constant electrical arc between the points contact area, they would wear down and change the dwell periodically, which led to readjusting the point gap or replacing them on a regular basis. With today’s cars and the computer-driven electronic ignition, dwell isn’t as big of an issue to maintain.

Testing the Secondary

Even though you can get the new guy in the shop to hang on to the end of a plug wire while you crank the engine over to check for spark, I doubt he’ll try it twice. Of course, you can also see a spark jump across an air gap with something like a spark tester, but the best way to observe the secondary ignition voltage is with an oscilloscope.

Oscilloscopes are more accurate, and with a lot of models today, you can’t even get to the plug wires or spark plugs without tearing off layers of protective engine covers or countless hoses and tubes. So, observing what’s going on inside the combustion chamber without tearing things apart will not only save you time, but also save you from changing parts that may not need replacing. Learning how to interrupt a secondary wave form doesn’t take long either. Once you’ve got the leads hooked up, the display adjusted and the engine running, chances are you’ll see the problem right in front of you without even turning a wrench.

Unlike using a spark tester, which only shows if there is spark or not, the scope can give you the value of that spark as well as the duration, the input voltage and the oscillations associated with the signal. If you’re unsure what it is supposed to look like, that’s not a problem either. There are several websites that offer known good patterns to verify what you’re seeing as well as offer helpful tips on how to interpret the scope readings.

Another advantage to using a scope to diagnose the secondary pattern is the amount of information that can be gathered by understanding the wave pattern — from finding a shorted/grounded plug wire or spark plug to finding an open or disconnected plug wire. Even a faulty injector can be diagnosed by hooking your scope up to the affected cylinder, performing a throttle snap and watching the firing line and the spark line.

I’m no expert when it comes to scope readings, so I spend a lot of time listening and observing other technicians and instructors on the use of a scope. I’ve seen some ingenious ways different techs have found to hook up a scope and read the secondary ignition — too many to list, that’s for sure. Once you’ve got the hang of using a scope and reading the secondary, you’re probably going to retire that old spark tester.

Practice when you can on a car without any secondary ignition problems so you can get familiar with what a good pattern looks like on your scope. Then create a failure, like an open plug wire or grounded wire, to see what happens. When you’re familiar with the pattern changes, diagnosing secondary ignition problems is going to get a whole lot easier and go a whole lot quicker.

Courtesy Underhood Service.