MODELS

- Buick LaCrosse 2006 2019

- Chevrolet Impala 2006 2020

- Chevrolet Monte Carlo 2006 2007

- Pontiac Grand Prix 2004 2008

CONDITION/CONCERN

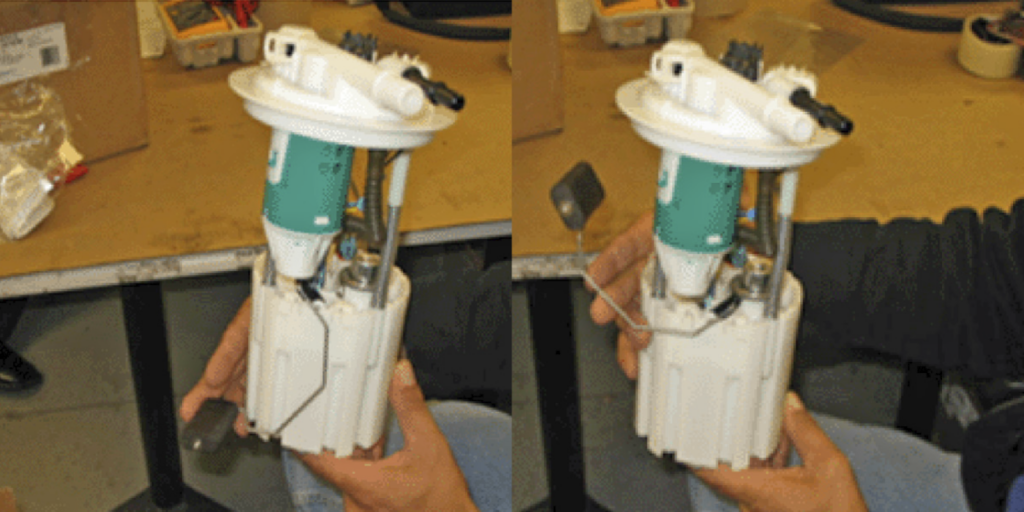

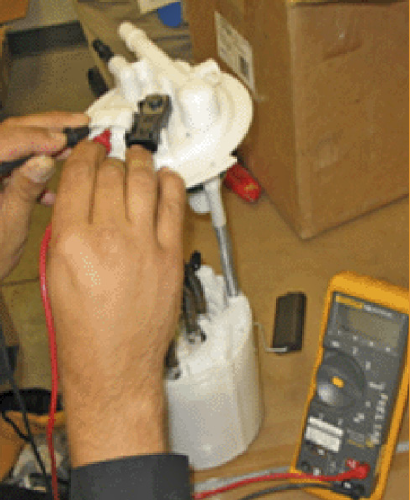

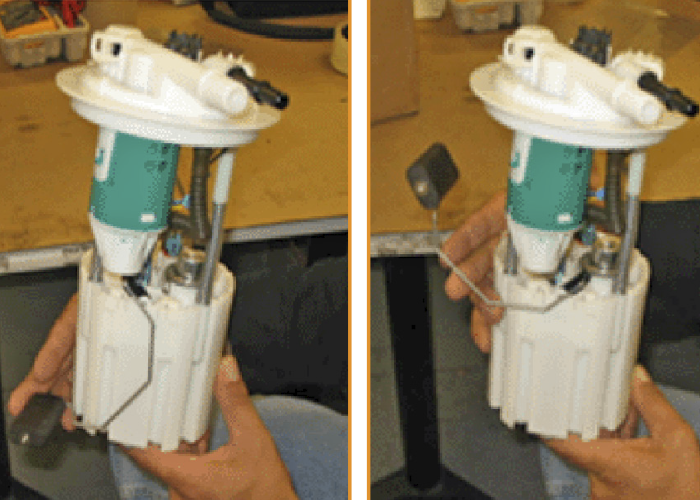

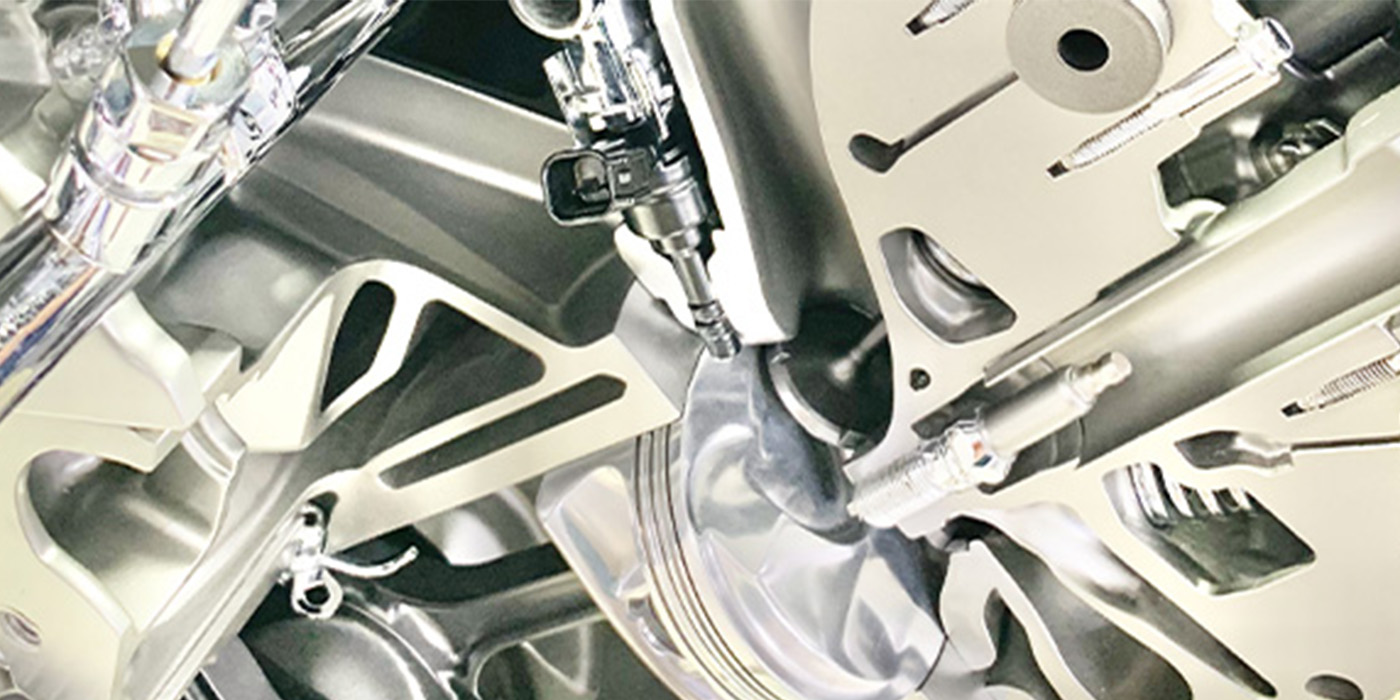

If the service information diagnostic leads to a potential level sensor failure at the component, test the circuit from the connector at the top of the fuel module. When testing the sweep of the fuel level sensor, slowly sweep the float arm from the empty position to the full position watching the ohm meter looking for a momentary O.L. or open reading. You should see the sweep range from approximately 40 ohms to 250 ohms, + or – 5 ohms.

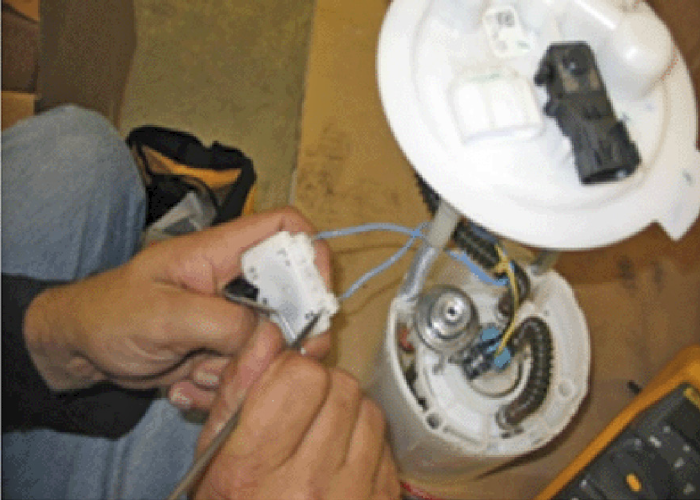

Do not remove the fuel level sensor from the fuel module unless you get a faulty reading during the testing of the sensor. This may cause damage to the fuel level sensor unnecessarily. If during testing you identify a faulty sensor, remove the sensor from the unit by lightly prying the lock tab on the fuel level sensor body inside the fuel level module.

Once sensor is removed from assembly carefully depress lock tabs on both sides of the sensor to remove the terminals from the fuel level sensor assembly. Install terminals into a new fuel level sensor.

Carefully, install the new fuel level sensor into module. Perform the sweep test again with your meter leads on the connector at the top of the fuel level module. Upon a successful sweep test, reinstall module into the fuel tank, reassemble the components and verify successful repair. If the sweep test fails with the new fuel level sensor installed replace the complete fuel module.