Who can benefit from these performance components?

Brakes are, conveniently, one of the most obvious automotive components to show wear, and drivers rarely go long between repairs once the car starts making the tell-tale squeaking or grinding noises. Even if the driver can somehow ignore the pulsation in his foot from a failing brake system, his passengers and passersby will likely remind him to “get those fixed!”

Because it’s a primary safety issue, drivers will typically agree to some recommended service procedures during a necessary brake job. Pads are usually a no-brainer. Rotor replacement may take a bit more effort. But calipers don’t always get the attention they deserve.

Most import and domestic vehicles come factory equipped with single-piston calipers. Their construction means they are adequate for normal braking and, frankly, they are cheaper for the OEM to spec and install than multi-piston calipers.

Brake calipers may be designed to last the life of the car but what does that mean? Is the car being driven the way it was designed? Have the related components been serviced on a timely basis?

Caliper Upgrades

Caliper replacement may be necessary in high-mileage vehicles because of fluid leaks or because the calipers are sticking. Stock replacement components will likely do the job just fine, but for customers who believe “fine” isn’t good enough, or if a customer is serious about improving braking performance, replacing stock single-piston floating calipers with aftermarket multi-piston fixed calipers is the way to go.

Multi-piston calipers found on high-performance vehicles including many import cars need special attention during a brake job. The more moving parts that are used to stop the car means the greater chance that a small problem in a system can lead to bigger problems.

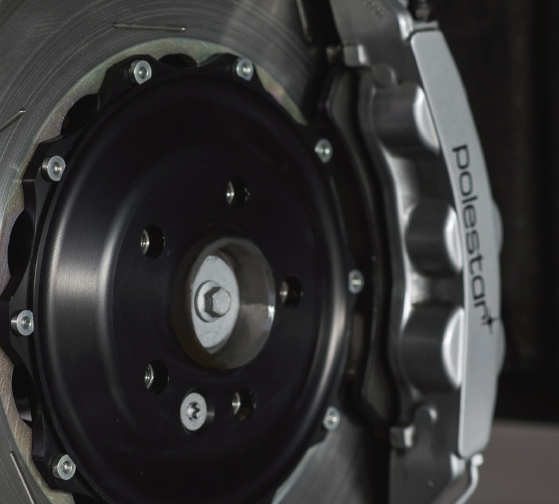

Aftermarket performance brake kits typically include multi-piston fixed calipers that replace the stock calipers, rotors with the same or larger diameter, new performance pads (typically some type of semi-metallic or ceramic/metallic formula), new braided stainless-steel front brake hoses and new caliper mounts (if required).

Most aftermarket performance brake kits use multi-piston calipers instead of single-piston calipers in order to multiply brake force. The amount of clamping force the caliper can apply to squeeze the pads against the rotor depends on the surface area of the caliper piston and the amount of force generated by the master cylinder. If hydraulic pressure from the master cylinder remains consistent, then increasing the surface area of the piston by using more than one piston will multiply braking force.

Another reason for using multi-piston calipers is to reduce pad flex for better clamping effectiveness and friction. If a caliper has a single, large piston and a relatively short pad, pad flex is usually not an issue. But if a caliper has longer pads (to increase the friction surface area), applying pressure only in the middle of the pad with a single piston may cause the ends of the pads to bow up slightly, with the most force being applied in the middle. So to ensure the full length of the pad contacts the rotor, two or more pistons are used to more evenly distribute the clamping force along the entire length of the pad.

To even out clamping force, some multi-piston performance calipers use different-sized pistons; typically smaller diameter pistons on the leading edge of the caliper and larger pistons behind it.

Most performance calipers are aluminum rather than cast iron and come powder-coated in a variety of bright colors. Some are also available with a clear anodized coating or are bright plated to resist corrosion and enhance their appearance. Installing a set of brightly colored calipers will certainly dress-up the appearance of any vehicle and enhance the look of the brakes behind alloy wheels.

Most of the aftermarket performance brake kits use fixed calipers rather than floating calipers. This is done so the calipers can squeeze the pads evenly from both sides. But this requires changing the caliper mounts and carefully aligning the calipers to the rotors when they are installed so the pads wear evenly. If a fixed caliper is not perfectly parallel to its rotor, the front and rear edges of the pads will not wear evenly.

Other Upgrade Considerations

The larger the rotors, the more brake torque they can generate when the brakes are applied. Up front, that’s a good feature to have. But in the rear, too much brake torque can upset the vehicle’s brake bias and cause the rear brakes to feel grabby and lock up prematurely. The fix is to either use a properly sized rear rotor, or to install an adjustable valve in the rear brake line(s) to reduce the pressure so the rear brakes don’t exert too much pressure when the brakes are applied.

Stopping is a safety concern, of course, but can also be a style issue.Today’s multi-piston calipers and performance brake components can give your customers the best of both worlds.

Article courtesy Brake & Front End magazine.