Complaint:

A 2006 Ford Focus with the 4F27E Transmission has complaints of harsh garage shifts as well as harsh lift throttle coast downshifts. All upshifts are perfect and no trouble codes are stored.

An exchange valve body complete with solenoids did not eliminate the complaints. The Mass Airflow Sensor was cleaned and checked and the complaints remained.

Where to go from here came up once a pressure gauge was connected the line pressure service port. The technician noticed that whenever the brake was applied, line pressure became slightly elevated. This pointed the diagnostics towards the stop light switch and the stop light circuits.

Cause:

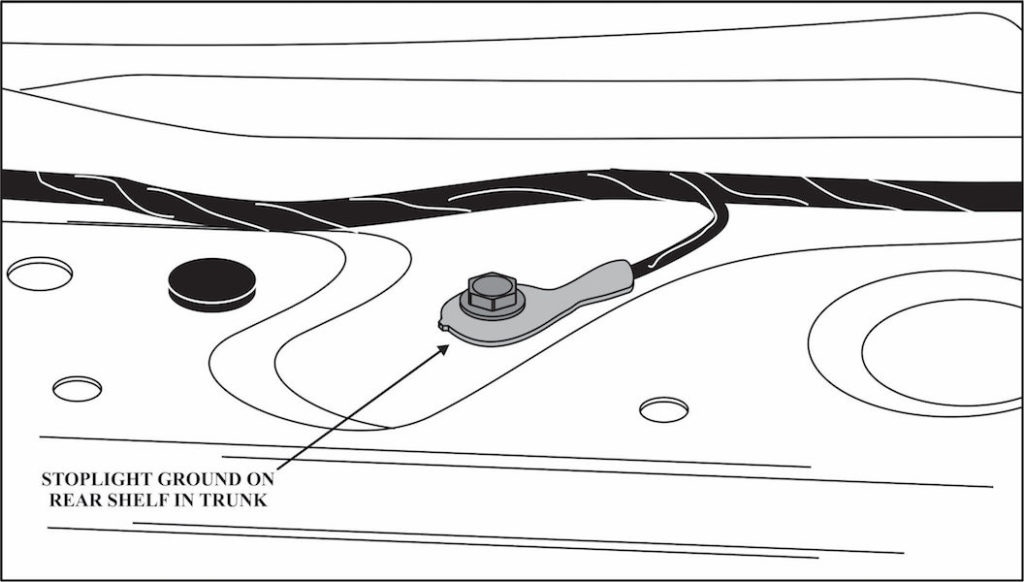

A poor stop light ground was found in the trunk. This required removal of the floor covering in the cargo area. These ground points are designated the G401 and G402 and are located across the rear of the cargo area, refer to figure 1.

Correction:

Once the stop light ground was repaired all the harsh shift complaints vanished.

NOTE: There was no definitive cause as to why the poor stop light ground would have an effect on line pressure. It can only be assumed that the poor ground created a feedback situation through the inhibitor switch due to the stoplight circuit seeking a ground path and affecting the PCM control of the line pressure control system, but this is only a guess.

This article appears courtesy of Transmission Digest.