FRONT CLICK NOISE AT LOW-SPEED TURNS

Models

- 2020 Dodge Durango

- 2018-2020 Jeep Grand Cherokee

- 2018-2020 Dodge Charger

- 2018-2020 Dodge Challenger

NOTE: This bulletin applies to vehicles equipped with Brembo 6-Pot Fixed Caliper Brakes (Sales Code BR7) or High Performance Brakes (Sales Code BNN).

Complaint

When making a sharp turn at low speed (parking lot) maneuvers, a click noise is heard. Most of the time, the noise can be heard if the windows are open.

Repair Procedure

- Remove both front brake rotors.

- Clean hub face where the rotor surface contacts the hub face to remove any dirt or corrosion, using scotch britepad or similar style scouring pad that will not scratch the surface. Clean all mounting surfaces as seen in Figure 1.

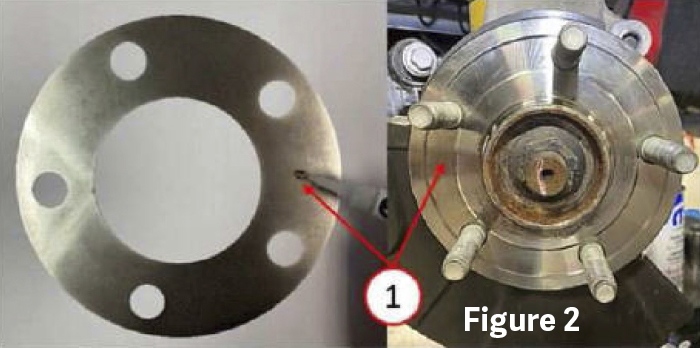

- Use a small amount of adhesive between the friction disc and hub to hold disc centered on hub (Figure 2).

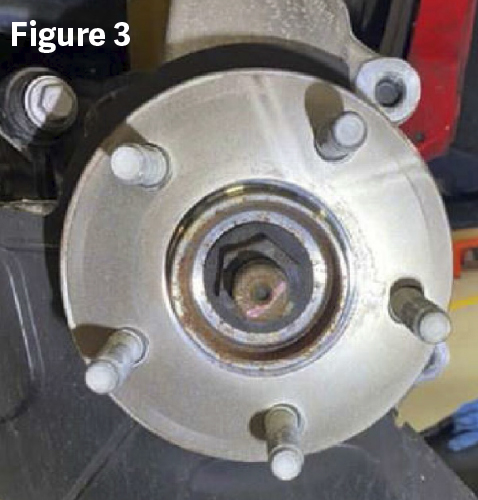

- Install the friction disc onto both hub flanges. (Figure 3).

- Put both rotors back onto the hubs and apply a small amount of adhesive in the center of the friction disc. Put both friction discs on the outside of the rotors .

- Finish installing both front brake rotors/calipers.

Parts Information

– 8530288AA Brake Friction Kit (Challenger and Charger)

– 8530289AA Brake Friction Kit (Durango and Cherokee)

This article is courtesy of Brake & Front End.