For a long time, the copper core spark plug ruled the roads. For under a dollar, you could buy a plug that would fit, but you had to gap the plug the correct distance between the electrodes yourself.

For a long time, the copper core spark plug ruled the roads. For under a dollar, you could buy a plug that would fit, but you had to gap the plug the correct distance between the electrodes yourself.

This was due to differing ignition system designs with different output voltages. You could even adjust the gap to suit modifications to the vehicle. But with the softer electrodes made of copper, chromium or nickel-iron, they eroded every time the spark plug fired. Eventually, the gap would open up or the shape of the center electrode changed to the point where it would cause a misfire.

In the 1990s, ignition systems changed with the introduction of fine-wire spark plugs. These plugs took advantage of increased ignition system outputs by utilizing small-tip electrodes made of, or plated with, hard precious metals like platinum, palladium or iridium. These plugs could last longer because the metals did not erode as fast as softer metals like copper.![]()

These improvements have changed the spark plug from a 25,000-mile item to a 100,000-mile item. During the past decade, we have seen spark plug design grow by leaps and bounds. It’s not uncommon to see a specific spark plug designed just for one engine’s combustion chamber design and flame front.

Gapping Plugs

Gapping Plugs

For modern fine-wire spark plugs, you should not measure the gap unless instructed by the manufacturer because you could damage the center electrode. But, it is still a good idea to inspect the new spark plugs for damage or defects. The majority of these plugs come pre-gapped from the factory.

On these types of plugs, bending the ground electrode(s) can alter the geometry and thermal performance of the electrodes to the point where it could cause a misfire.

On older applications, gapping may still be required. Gapping specifications can be found in the service information or emissions tag under the hood. Also, gapping specifications can be found in electronic and paper catalogs.

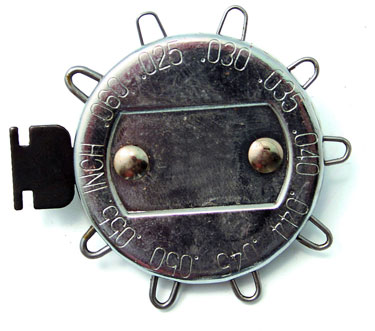

Measuring the gap requires the right tools. A coil-style gap gauge will work for copper core plugs. For fine-wire or precious metal plugs, it is recommended to use a wire-type gauge.

If it is necessary to widen the gap, do so with a tool that only pulls back on the ground electrode without touching the center electrode or the porcelain. To close the gap on a plug, gently tap the plug, electrode first, on a hard surface.

Courtesy Underhood Service.