Engine building facilities are often stuck between a rock and a hard place. When it comes to finding new employees they often want young guns who are eager to work and have experience. So where do they find them?

Today’s tech schools are preparing students to work in all areas of the industry, from racing teams to engine shops. But, how much do they know after graduation? We talked to Paul Higgins, a longtime instructor and race team coach for the University of Northwestern Ohio (UNOH), to find out.

Higgins says that UNOH offers multiple automotive degree programs within the School of Technology. The High-Performance Program is separate from some other programs, but students may combine majors or concentrations with dual degrees.

“Students can get either a high-performance diploma or an associate degree,” Higgins says. The diploma program is 28 months, whereas the associate degree is 33 months. “There are also programs where students can combine automotive and high-performance, or diesel and high-performance, but typically the high-performance program itself is a standalone program. Some students choose to do a dual program or a multi-program.”

According to Higgins, a student may complete his or her associate degree in the college of technologies and then transfer that into a bachelor’s degree program. “When you graduate in the college of technologies with an associate’s degree, you have the option of taking an automotive management program, which you can go into and finish that out as a achelor’s degree in automotive management. If you came to the university and just wanted to take a straight bachelor’s degree in business marketing or sports marketing, or accounting, and you just did a typical college-type program, you would get into the high-performance end. But if you took the tech program, then you also have the latitude of being able to turn that into a bachelor’s program with added-on classes.”

Opened in 1920, UNOH was mainly a college for secretarial work. Over the years, the school and campus have expanded and today has about 4,000 students annually, studying everything from nursing and accounting to robotics and alternative fuels.

“Whether you’re in agricultural, HVAC, robotics, automotive, diesel, high-performance, alternate fuels, all of that is under the College of Applied Technologies,” Higgins notes. “There’s a College of Business, which is just straight business – accounting and business management programs. And then there’s the Graduate College for moving on into master’s degrees. There’s also healthcare.”

Most of the students who come into the College of Technology are looking to either join a race team or work at a dealership or engine/hotrod shop, but some students have aspirations to run their own shop someday. These students would need some business and management classes as well as focusing on automotive technology or high performance.

“These folks do what we call the two-plus-two, which is a bachelor’s degree in automotive technology supervision,” Higgins explains. “It means taking the two-year tech classes, whichever course they desire in automotive. But, if you want to be an automotive shop owner, you’ll want to learn some more skills that will help you be a better owner, manager, etc. Then it would be suggested to have them take the automotive tech program and add on automotive technology supervision, which goes into being a shop manager. Many students do that and then become service writers or dealership managers.”

Before the pandemic hit last year, Higgins says their attendance level was at a high. However, it’s been an enormous challenge to get through 2020, as it has been for nearly everyone on the planet. “We were doing well before the pandemic. Although, we are always looking to put more students in because we’re a private university that is tuition-driven. It’s a not-for-profit entity. Once the pandemic happened, we shut down from about April through August with no students on campus whatsoever. We did do a lot of virtual online classes for the general education classes. Many students, even though they’re in the tech program, have certain required GE classes, so we were able to teach those throughout the summer shutdown.

“Now that we have come back, the student population is coming back too. They still have to wear masks and social distance. That can be a challenge in such a hands-on teaching environment as automotive and racing.”

Speaking of racing: the high-performance curriculum covers everything from circle track to drag racing. “We cover all the different aspects and don’t just stick to one type of racing,” Higgins says. “In our steering/suspension class, they’ll include circle track asphalt, dirt, drag racing, and even off-road racing. There’s a little bit of everything.”

UNOH also offers a driveline class in the high-performance program. “We have our high-performance drive lines classes, which I always say goes from the back of the motor to the tires,” he says. “Whether it’s a clutch-style driveline, automatic-style driveline, we go through all the different racing clutch applications, racing transmissions, both automatic and manual. For differentials, we cover quick changes, narrowing rear-ends for dragsters, drag car rear-end set up, dirt car set up all the way out to the tires. It’s basically anything from the back of the crankshaft to where the power hits the ground.”

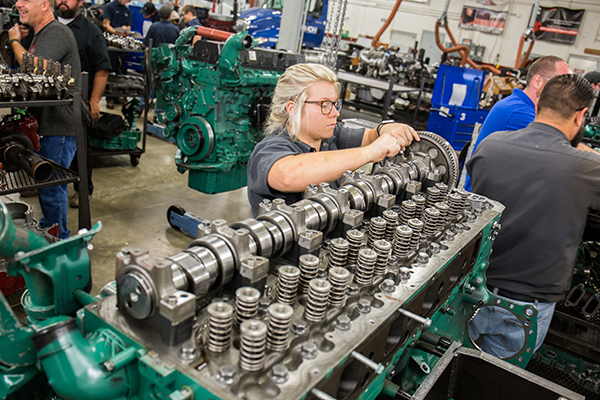

While there’s plenty of classroom work and general education studies, the bulk of students’ time is spent working on something with their hands.

“Probably a good 70% of our classes are hands-on,” states Higgins. “They’re tearing apart everything from Jericos and Bert’s for the dirt guys to some asphalt transmissions and the Powerglide, because that’s big in grassroots drag racing.”

Higgins says they have several machining classes along with some prerequisites in engine repair on the engine side of things. “We have a basic engine machining class, which the prerequisite would be automotive engine diagnosis and repair, where they learn to take engines apart, do the measurements on an OEM-based engine. In engine machining, we teach them the typical machine shop procedures performed in a typical machine shop: valve guides, valve seats, cutting valve seats, power hones, block surfacers, head surfacers, align hone, and things like that. There are 13 different areas where the students have to test off of in that class to get proficiency on their procedures. After that, there is a custom engine building class where we take it to another level with some more exotic equipment, CNC machining, CNC-controlled hones, etc. In that class, there are more errors they have to be proficient is solving. A benefit in that class is if they have their own project, they could then theoretically build an engine for themselves or one of the school’s training aids or one of our school race cars.”

Higgins says that most of the motorsports team engines are now built by the team. Students also have the option of taking the high-performance fuels class. “This is anything to do with tuning the engine, the chassis dynos, or water-break engine dynos. On a side note, UNOH used to host the Engine Masters Challenge for quite a few years, so they have a lot of understanding and a great facility for dyno projects.

“In the fuels class, we start with what makes the engine work: airflow, the combustion process, and all that. Then we get into head porting and flow testing with our flow benches. We start with carbureted engines and then move into EFI.”

Higgins says that when students get into EFI tuning, they typically use HP Tuner because students will go in and edit the fuel maps. “They just want to go in and re-edit stuff. We work with everything from my LS Chevy running on HP tuners to small-block Chevy’s running Holley EFI. They’re easy-to-learn systems that are fully programmable. We tune power adders too, now and then, depending on what we’ve got on the dynos.”

Higgins adds that the school has a couple of dedicated dyno mules that run on the chassis and engine dyno every day, and the students do blow them up every so often. “We have pretty good success on the chassis dynos, but the engine dynos are more of a challenge. We built one that was a 520 hp small block that we ran on the engine dyno. I usually figure that every class will put about 300 runs on a dyno engine in six weeks. We have classes three times a day, so that’s a possibility of 900 dyno pulls in six weeks, and we run eight sessions a year, so that motor went for four years before it finally broke.” EB

The Best Free Class You’ll Ever Take

Aside from the High-Performance program, UNOH runs a racing team that the students run. It’s an extracurricular activity in which the students have to maintain a certain grade-point average to be selected for the team.

“The team started in 2006, and we worked out of the back of the 600 building back then,” says Paul Higgins, who coaches the racing team when he’s not teaching. “In 2013, we moved into our own building. We have our own high-performance motorsports team complex, which is separate from the high-performance program.”

Higgins notes that the team works in the shop four hours a day during the week to prepare their fleet of racecars for the weekend events at Limaland Speedway nearby. Higgins explains to student racers every year, “It’s the best free class you’ll ever take.” And that is not a joke. The team has its own tractor-trailer and has traveled as far as Florida for championship races at the end of the year. This year may be slightly different because of COVID restrictions, but they are still planning an entire season at Limaland.

From working on the race team and graduating from the high-performance program, Higgins’ students and racers have gone on to more extraordinary things such as IndyCar, NHRA, NASCAR, and various performance shops throughout the country. UNOH has a formula that works, and students and shops are better off because of it.

This article is courtesy of Engine Builder.