Since 1996, the majority of Subaru vehicles have followed the symmetrical all-wheel-drive recipe. While they are not known for drivetrain problems, Subarus are known for difficult drivetrain noise diagnostics. Part of the problem is the layout of the components. The other part of the problem is the driver not being able to describe the problem or driving with an issue hoping it will heal itself.

Is It The Driveshaft?

The main symptom of driveshaft problem is noise when shifting from reverse to forward. Some driveshaft noises will change when driving as the shaft is rotating or as the vehicle is braking or accelerating.

Most late-model Subarus use a two-piece driveshaft. In the center you’ll find the center bearing that supports the driveshaft. Inside is a ball bearing mounted in a rubber cushion that attaches to a crossmember. The cushion allows vertical motion at the driveline and helps isolate the vehicle from vibration.

Premature failure of the center bearing could result of too much driveshaft angle or damaged rubber casings. For some models, it’s the close location to the exhaust system that shortens the life of the rubber in the center support bearing.

A worn center support bearing will cause the driveshaft to move and possibly strike the floor or exhaust system. The noise will change as the vehicle brakes and accelerates. In rare cases, the sealed bearings will fail and cause noise when first driving and the bearing is cold. This noise can be a low pitch growl

Universal joints will make clicking noises and then clunks. Most original universal joints are sealed. The seals at the trunnions can wear and the grease can escape, causing wear to the needle bearings. Replacing a universal joint is straightforward. Just remember to mark the flanges so the driveshaft goes back in the same way so it is not out of phase.

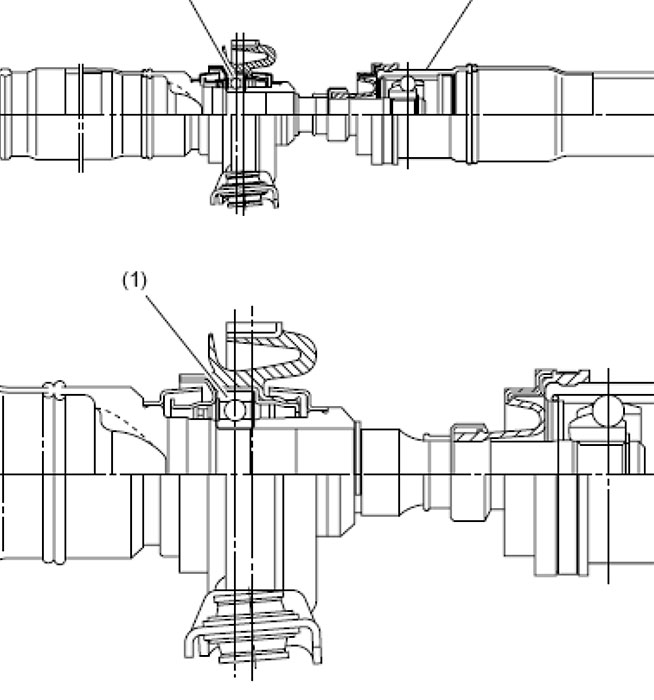

To reduce noise, some Subaru driveshafts use a special constant velocity joint to connect the two pieces of the driveshaft. The center joint is called an EDJ by Subaru. It is a high-efficiency compact double offset joint that can extend and retract in a wide range of axial directions. If the boot is damaged, the joint won’t last long.

Is It The Axles?

The symptoms of a bad axle can be clicking that changes with the steering and suspension movement. The noise is caused by wear to the balls, bearings and cup of the joint.

When a CV axle fails, it is for a reason. Rarely will an axle fail because it is just worn out. The failure of an axle can usually be traced to a torn boot, alignment issue or a problem with components attached to the axle.

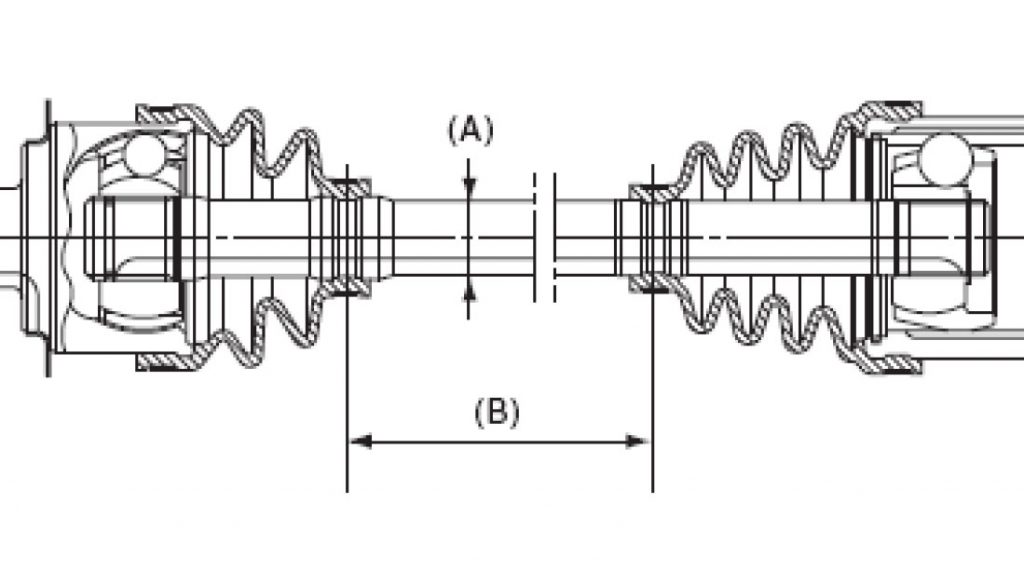

One of the unique aspects of working on a Subaru is the parts. Different combinations of transmissions, engines and drivetrains can increase the complexity of ordering a new axle. If you get the wrong axle, it can either be too long or short but still fits on the vehicle. If the axle is too long, it can bottom out the inboard joint and cause noise and vibrations. If it is too short, it can pull out of the inboard joint. To prevent this, make sure you use the VIN and make for ID, not just the engine and transmission. Don’t assume a WRX axle will fit an RS model.

Is It The Differential?

Most Subarus are all-wheel drive, which means there are two differentials that can cause noise problems. If the owner has not serviced the differentials, wear can occur to the ring and pinion. This can cause noise and lash in the drivetrain.

The most critical inspection point for a Subaru is where the axles go into the transmission. If the seals are leaking, you need to first diagnose why they are leaking. A seal rarely leaks on its own. When the fluid level drops inside a differential, it can cause excess heat and wear.

Often the cause of a leak is a blocked or restricted breather. The breather allows for air to be moved in and out as the fluid heats and cools. If it is blocked, it can cause pressure to build up in the differential housing. The pressure pushes on the weakest point, the flexible lips of the axle seal. The other source of leaks is the condition of the surface on the axle the seal’s lip rides on.

Article courtesy ImportCar magazine.