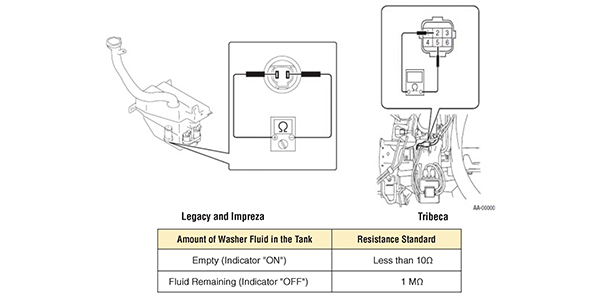

Models:

2010-’18 Legacy & Outback

2012-’18 Impreza

2006-’18 Tribeca

The purpose of this Service Bulletin is to explain the inspection, diagnosis and replacement procedures for the washer fluid level sensor.

1. Release the retaining clips and lower the L/F splash guard to gain access to the washer fluid tank and fluid level sensor assembly.

2. Check for evidence of poor contact of the washer fluid level sensor wiring harness connector.

3. Does the low washer fluid warning light illuminate after draining the washer fluid? If YES, does the low washer fluid warning light go off after refilling the washer fluid?

YES: Fluid level sensor operation is normal.

NO: Proceed to step 4.

4. Remove the wiring harness connector from washer fluid level sensor, then measure the voltage of the vehicle-side connector using a volt meter.

Is the voltage approx. 8.5 V or more?

YES: Proceed to step 5.

NO: Check the harness carefully and verify the input / output signals to the combination meter and/or the integrated unit as specified in the service information. If harness and signal checks are all within specification, combination meter and/or integrated unit replacement may be necessary.

5. Does the washer fluid indicator in the combination meter illuminate if you connect the terminals of the washer fluid level sensor wiring harness connector together?

YES: Proceed to step 6.

NO: Check the harness carefully and verify the I/O signals to the combination meter and/or integrated unit as specified in the service information. If harness and signal checks are all within specification, combination meter and/or integrated unit replacement may be necessary.

6. Using a voltmeter, measure the resistance of the washer fluid level sensor as shown.

Courtesy of Mitchell 1.