ECM And PCM Calibration Numbers

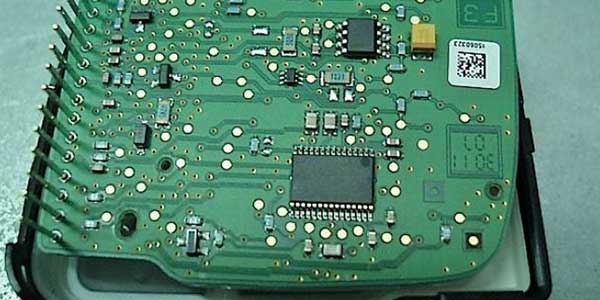

Finding out if the vehicle has the latest version or calibration on a module is a required step.

ECM Damage

Engineers have devised two strategies that can be called the “immune system” for the electrical system.

Engine Control Modules (VIDEO)

Accurate diagnosis of any suspected ECM-related fault is important. This video is sponsored by The Group Training Academy.

ECM/PCM Communication Issues (VIDEO)

Before you swap out a module that won’t communicate, do a few simple inspections. Sponsored by The Group Training Academy.

Tech IQ: Getting Rid of Code P0315

The code might set again when the engine is cranked. This video is sponsored by Auto Value and Bumper to Bumper.

ECM No Communication Issues

The source of the problem could be software, electrical or mechanical.

Understanding Five Volt Reference Signals

A 5-volt reference flows through a sensor with a resistance that varies according to changes in temp., pressure or position.

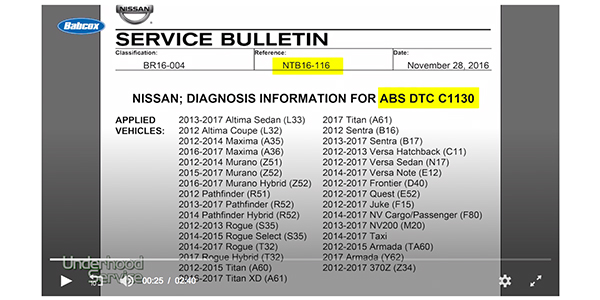

VIDEO: How To Resolve DTC C1130 For Nissan Vehicles

Andrew Markel discusses how to resolve chassis DTC C1130 and how it might not be an issue with the ABS system, but the ECM.

VIDEO: ECM Alternator Regulation; No More Full Field Testing

Andrew Markel explains how modern alternators are designed to have their loads regulated by the ECM, eliminating the need for full field testing.

Outsmarting The Smart Cars: ECM Replacement

The ECM’s (engine control computer) function is to control emissions, monitor and regulate engine functions as well as optimize engine performance and fuel consumption.

VIDEO: Stop-Start System Service Opportunities

Andrew Markel discusses service opportunities for vehicle stop-start systems and how several modules are involved in the activation of the feature.

Restoring Engine-Computer Communications

For this month’s Real World case, we will attempt to provide a plan of attack for communication issues on General Motors products with the Class 2 Protocol. Our diagnostic journey begins with a 2004 Chevrolet Tahoe. This vehicle was tested at the EPA test facility in our area and it was determined that there is