Mazda Front Camera Calibration (VIDEO)

Joe Keene discusses how to calibrate the front camera on a Mazda 6 after the windshield was replaced.

Mazda IActivsense ADAS

Mazda’s ADAS technologies use radar, cameras and lasers to identify objects and hazards and help drivers be safer.

Mitchell, Mazda Partner For U.S. Collision Repair Network

New program reaffirms Mazda’s support of proper, safe repair of collision-damaged vehicles.

Engine Build: Twin-Turbo 13B Mazda Rotary Engine

When it comes to engines, the Mazda rotary is an entirely different animal. Find out what went into this build.

Mazda SkyActiv Service Tips

These engines have been reliable, but there are four pattern failures you might see at your shop.

Making Sense Of Mazda’s i-ACTIVSENSE ADAS

Most Mazda models require a static calibration procedure with targets mounted at precise distances.

Building A Stickier Miata: Mazda MX-5 Suspension Upgrades

Many Miata fans love the handling and performance as much as the affordability of these little two-seaters.

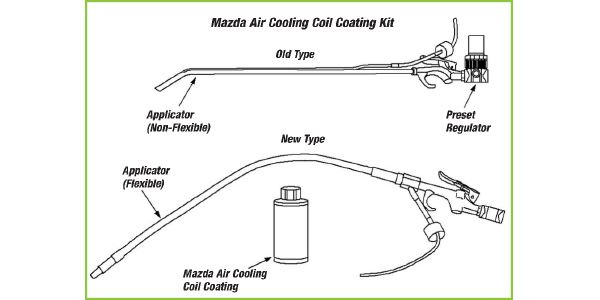

Mazda Tech Tip: Air Conditioning Musty / Mildew Odor

A musty odor may come from the vents when the A/C system is operating. It is most noticeable when the A/C is first turned on.

2004-2013 Mazda3 Brake Job

A key service issue for 2004-2013 Mazda3s concerns the hydraulics and ABS system. Here’s what to look for.

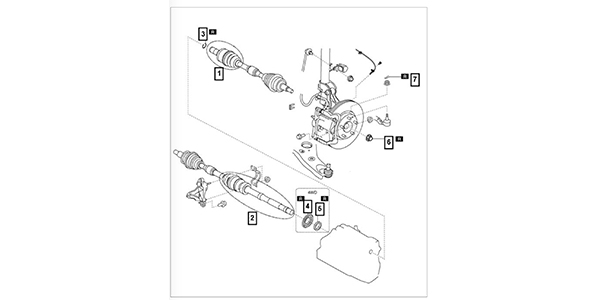

Mazda Tech Tip: Vibration Felt Through The Floor/Seat/Steering Wheel

Some customers may complain about a vibration that is felt through the floor, seat and/or steering wheel while driving under moderate acceleration, at speeds of approx. 25-30 mph (40-50 km/h).

Alabama High Schools May Become Training Grounds For Toyota-Mazda Plant

The curriculum in auto technology classes in the Decatur, AL, area will help prepare students to obtain jobs at the Toyota-Mazda plant.

Drifting: An Education

It’s a special moment seeing your project car come to life on the track, but it’s not every day you get to see your auto instructor crash it. For a dozen Rolling Meadows High School auto technology students, their drift car project is continuously a work in progress; getting better and better after each race.