Serpentine Belt Inspection Checklist

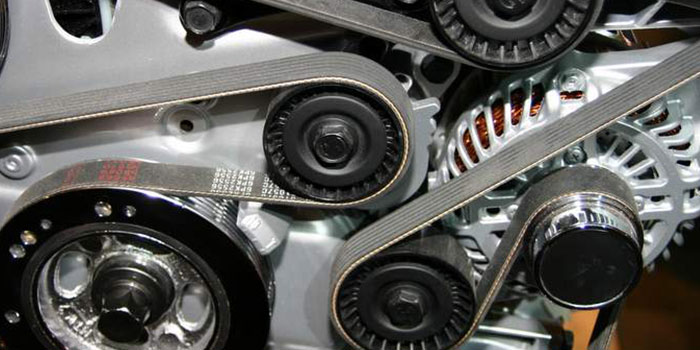

You might have only one chance to sell a customer a new serpentine belt. With belts lasting roughly 90,000 miles, proper inspection at the time of failure is critical not only for selling the belt, but also for ensuring add-on sales and better customer satisfaction.

Serpentine Belts: Inspecting And Replacing

A technician’s senses are often the most valuable tools in helping assess what repair or replacement parts are needed on a given job. Specifically, the ability to visually inspect parts for wear and tear to know when it’s time for replacement is the calling card of any successful technician. But when it comes to modern serpentine belts, you can’t trust your eyes anymore to tell you when it’s time for a new belt.

Diagnosing Belt Wear

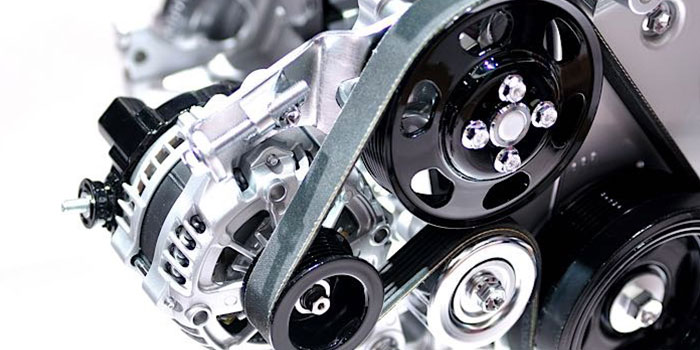

The original equipment belts on late-model vehicles are made of synthetic materials and are far more heat-resistant and wear-resistant than older materials. These innovations mean serpentine belts may last up to 100,000 miles before they need to be replaced. If a belt fails sooner, you need to be a detective and investigate why it failed.

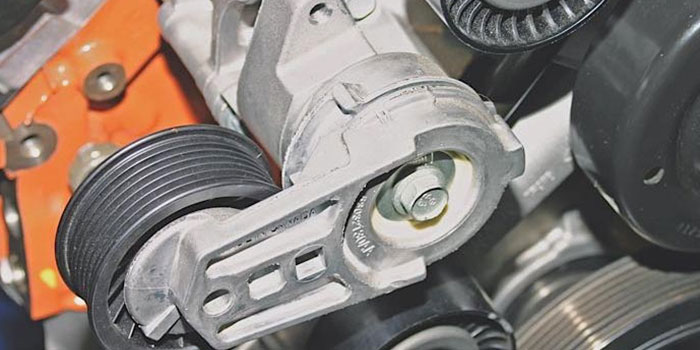

Selling The Complete Serpentine Belt Job

Technicians and customers have pretty much accepted that the accessory serpentine drive belt should be replaced between 90,000 to 100,000 miles. It is a “slam dunk” sale to just replace the belt, but does that replacement belt have the same chance to survive the same mileage? Chances are in the next 90,000 to 100,000 miles the replacement belt will have to deal with problems the original belt did not – a worn tensioner, idler pulley bearing failure or component alignment issue.