Undercover: Why Shocks And Struts Fade And Fail

Most shocks and struts today are “gas-pressurized” with nitrogen to minimize fluid foaming when the piston is pumping back and forth.

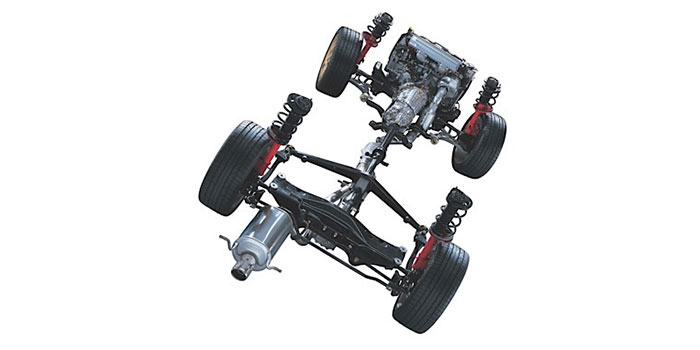

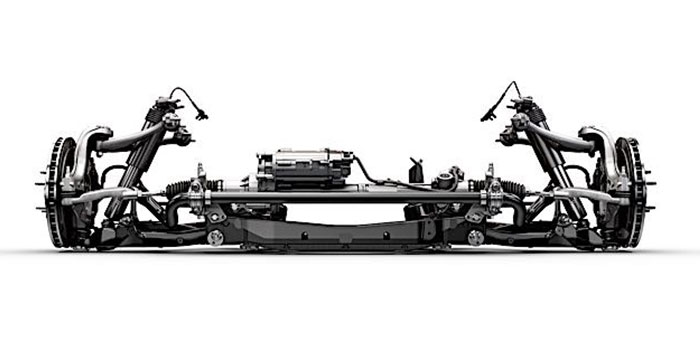

Undercover: Lessons In Off-Road Suspension Systems

There’s a lot more to building a rugged off-road vehicle than just raising the suspension height and installing big tires and wheels.

VIDEO: Sway Bar Link Noise On Nissan Vehicles

Andrew Markel explains how sway bar geometry can lead to suspension noise on modern Nissan vehicles.

Electronically Adjustable Dampener Diagnosis

Electronically adjustable shocks and struts use conventional mono-tube and twin-tube oil-filled dampeners. The rods, gas chambers and piston have the construction of passive units.

VIDEO: Shock Wear Maintenance

Andrew Markel goes over what can wear out on a shock assembly and why it is important to check the inside of a shock as well as the outside.

Torque-To-Yield Suspension Components

What do some ball joints, tie rods and suspension components have in common with engines? The answer is torque-to-yield (TTY) fasteners.

Spotting Bent Suspension Components

Normal driving usually won’t knock the wheels out of alignment or damage the suspension. However, normal driving also involves encounters with the unexpected, which often include potholes, curbs, railroad crossings (which are famous for being rough), parking lot speed bumps and other things that jar and stress the suspension.

Spring Is Pothole And Bearing Season

The classic symptom of a bad wheel bearing is typically a cyclic chirping, squealing or growling noise that changes in proportion to vehicle speed. The sound may only appear or disappear at certain speeds. The noise may get worse when turning, or it may disappear momentarily. So, it’s difficult to make a diagnosis based on noise alone.

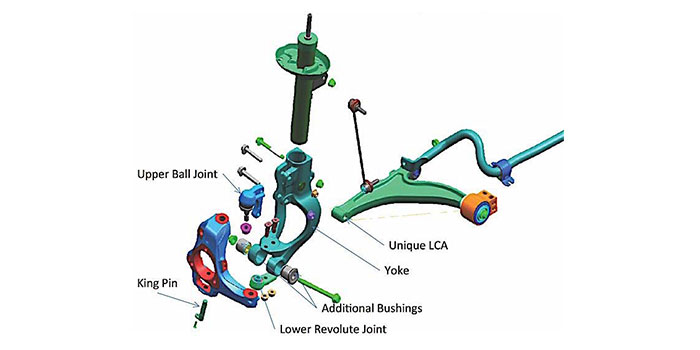

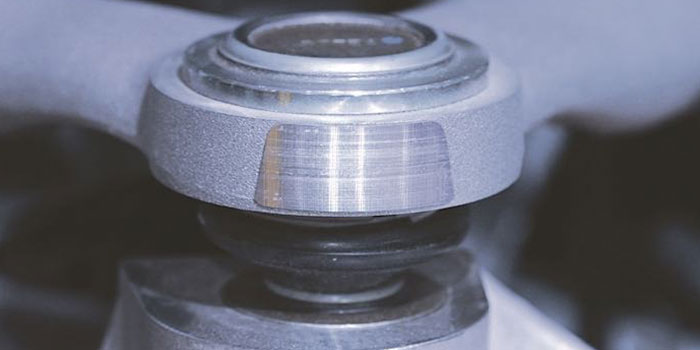

Ball Joint Engineering: Greasable And Sealed

One of the most frequent questions from my undercar customers is in regards to the availability of “greasable” chassis parts. Sealed-for-life components are very common at the OEM level, but many technicians have a definite preference for aftermarket greasable components. This poses the question: If greasable suspension joints are so popular, why don’t many modern suspensions have grease fittings anymore?

Tie Rod Inspection: Discovering The Danger Zone

Excessive tie rod play is difficult to ignore for any driver. It may start with tire wear on the inner edge of the front tires. Next, there could be a slight knocking during braking or acceleration. Last, tie rod play could manifest itself in a knocking noise while turning.

Active Ride Control Diagnostics

In the 1990s, adjustable valve shocks and struts were all the rage. These systems had two or three comfort and sport settings that could be changed with buttons on the dash. These systems played the role of firming up the suspension if the driver wanted a sporty feel while driving. These systems have evolved to the point where they can actively change dampening characteristics in milliseconds.

The Benefits Of Loaded Struts

In addition to the strut itself, a loaded strut includes the upper strut mount, strut bumper and boot, spring seat and insulators, and coil spring. Prior to the availability of loaded struts, our choices were to source each of these parts individually or reuse the parts where replacements weren’t readily available.