Axle Torque Procedures

Guessing the correct torque setting is a bad idea.

Five Spark Plug Service And Replacement Tips

Most articles will tell you to use a torque wrench, but they never explain why.

VIDEO: Torque Wrenches and Wheel Bearings

Are you using the correct torque wrench for the job? This video is sponsored by BCA Bearings by NTN.

VIDEO: The Right Amount Of Torque For An Oil Change

When tightening the oil filter or drain plug, more torque does not mean a tighter seal. This video is sponsored by FRAM.

Bondhus Releases Torque Limiting Screwdrivers

Features include an audible “click” when the pre-set torque level is reached.

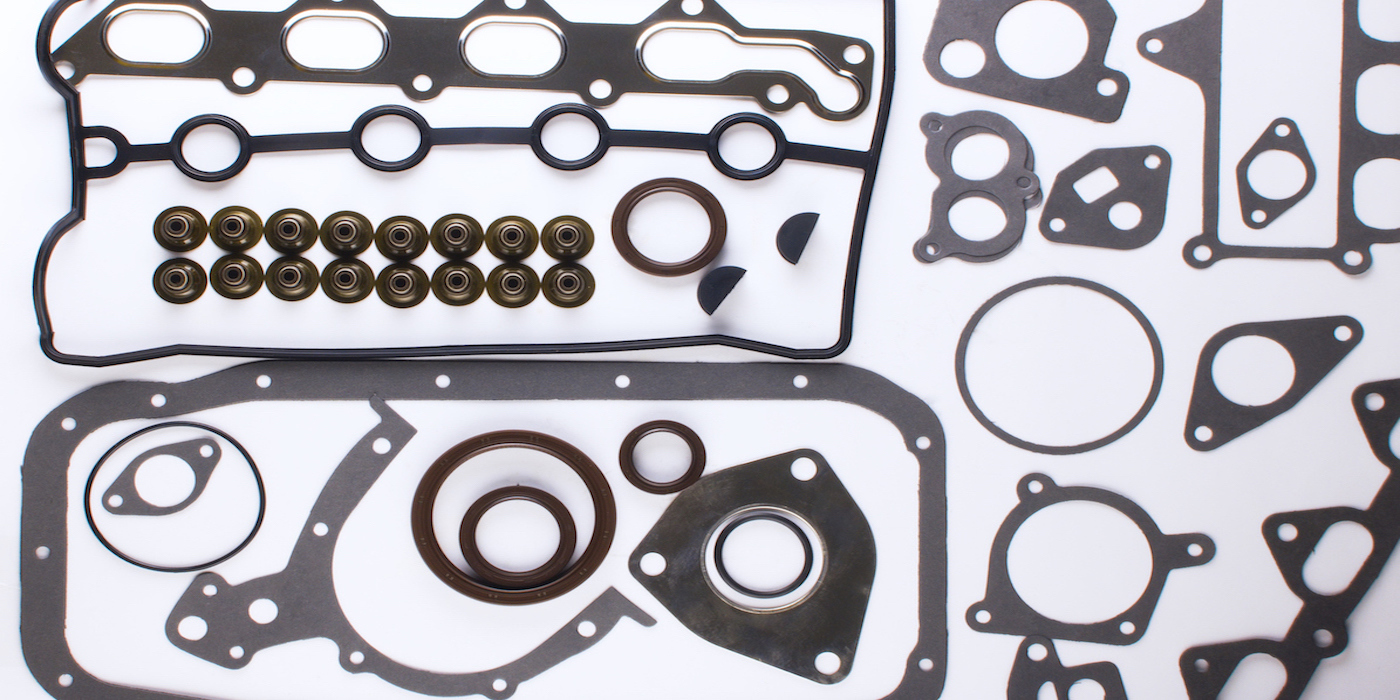

VIDEO: Can A Gasket Change Torque Specifications?

Learn how to find info on gasket torque specifications from OE and aftermarket manufacturer sources.

Milwaukee Launches Controlled Torque Impact Wrench

Milwaukee Tool has announced its new M18 FUEL 1/2″ Ext. Anvil Controlled Torque Impact Wrench w/ ONE-KEY.

VIDEO: Finding Torque Specifications For Fasteners

All fasteners on a vehicle require a specific torque to prevent damage to components, or the fasteners themselves. Andrew Markel explains how to find torque specifications.

GM Tech Tip: Torque-To-Yield TTY Fastener Use And Reuse

A fastener with a torque + angle specification must be tightened first to the torque part of the specification and then tightened further by the addition of the specified angle. The angle must be applied relative to the mating fastener.

Video Tech Tip: Torque vs. Horsepower

Video Tech Tip: Discussion on torque versus horsepower and how to determine which is more important when creating an engine package. The following is from Automotive Video Inc.