Ford 3.5L EcoBoost Turbocharger Oil Leaks

Ford has revised the service information for the inspection and pinpoint tests of the turbocharger and oil lines.

Diesel Turbocharging Basics

There’s a reason diesels typically utilize compound turbo setups instead of twin turbochargers.

Turbochargers on Minis

No matter if it is a BMW or MINI, when the engine stops turning, the oil flowing to the turbocharger stops.

Turbocharger Topics

Turbochargers have made a comeback – and it’s been quick.

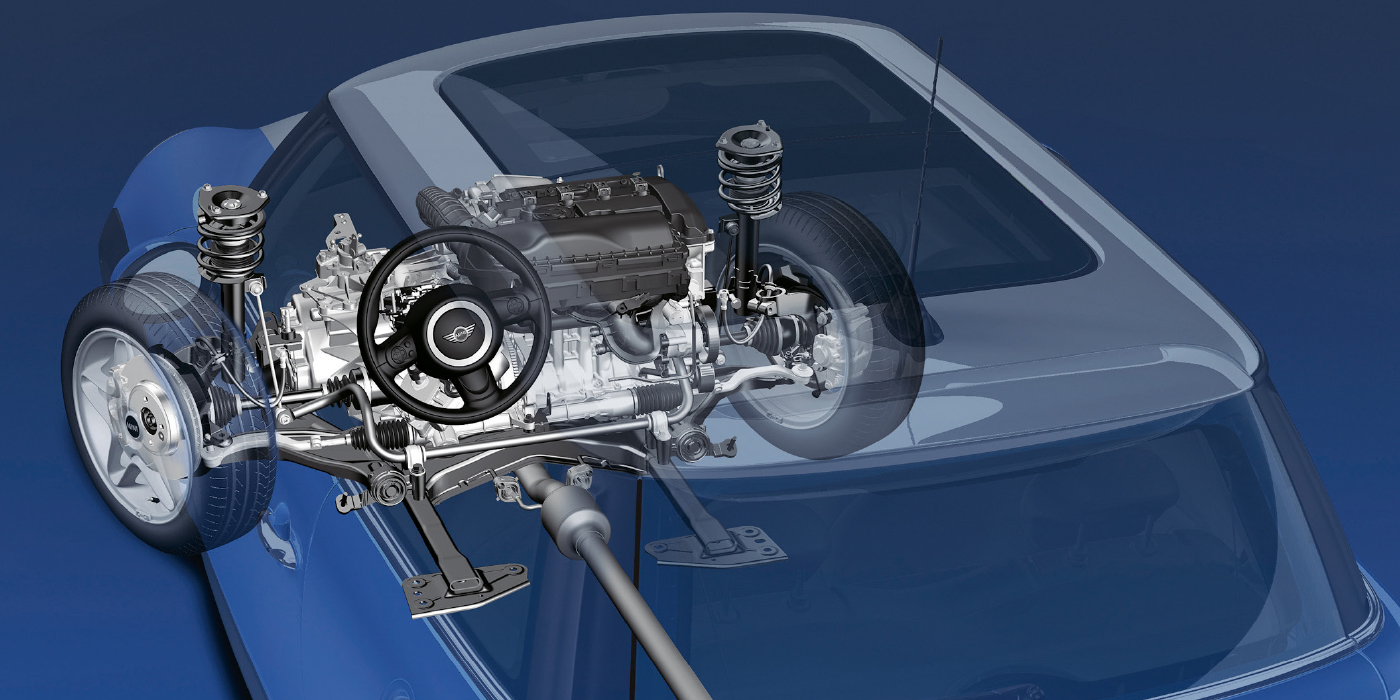

MINI Turbo Service

With more than a million MINIs on the roads, a lot of opportunities exist for servicing brakes and chassis.

Turbocharger Overview and Common Weak Points (VIDEO)

How does a turbocharger work? Let’s talk about it in simple terms. This video is sponsored by Standard Motor Products.

Best Practices for Turbo Services (VIDEO)

Turbo performance can only be impaired by mechanical damage or debris. Sponsored by Standard Motor Products.

What Turbo Kit Is Right For You?

Turbocharger kits come with many different parts that all require attention when buying – quality matters.

Verifying Boost Pressure Diagnostics

The best way to discover if an engine controls the boost pressure is the actual data PIDs for boost on a scan tool.

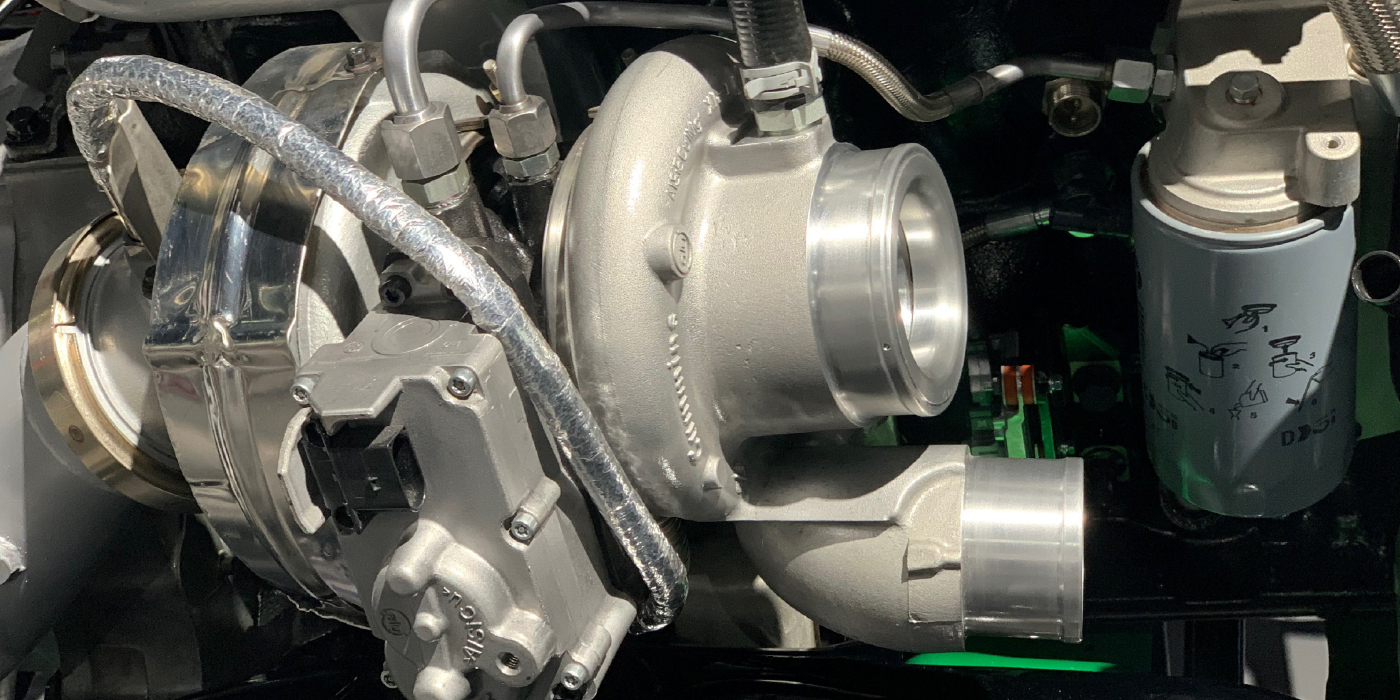

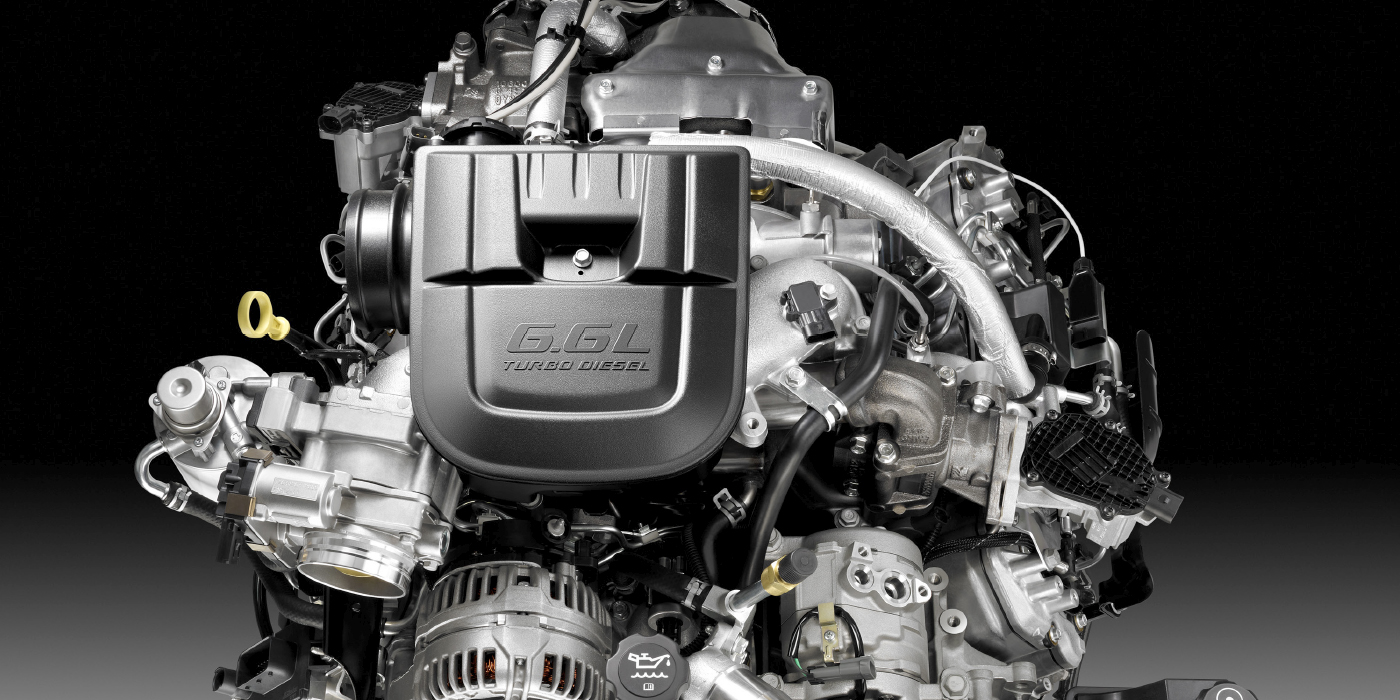

Duramax 6.6L Turbocharger Replacement

No matter the symptoms or damaged parts, the root cause of the failure must be diagnosed and resolved.

Duramax 6.6L Turbocharger Replacement (VIDEO)

No matter the symptoms or damaged parts, the root cause of the failure must be diagnosed and resolved. Sponsored by Cardone.

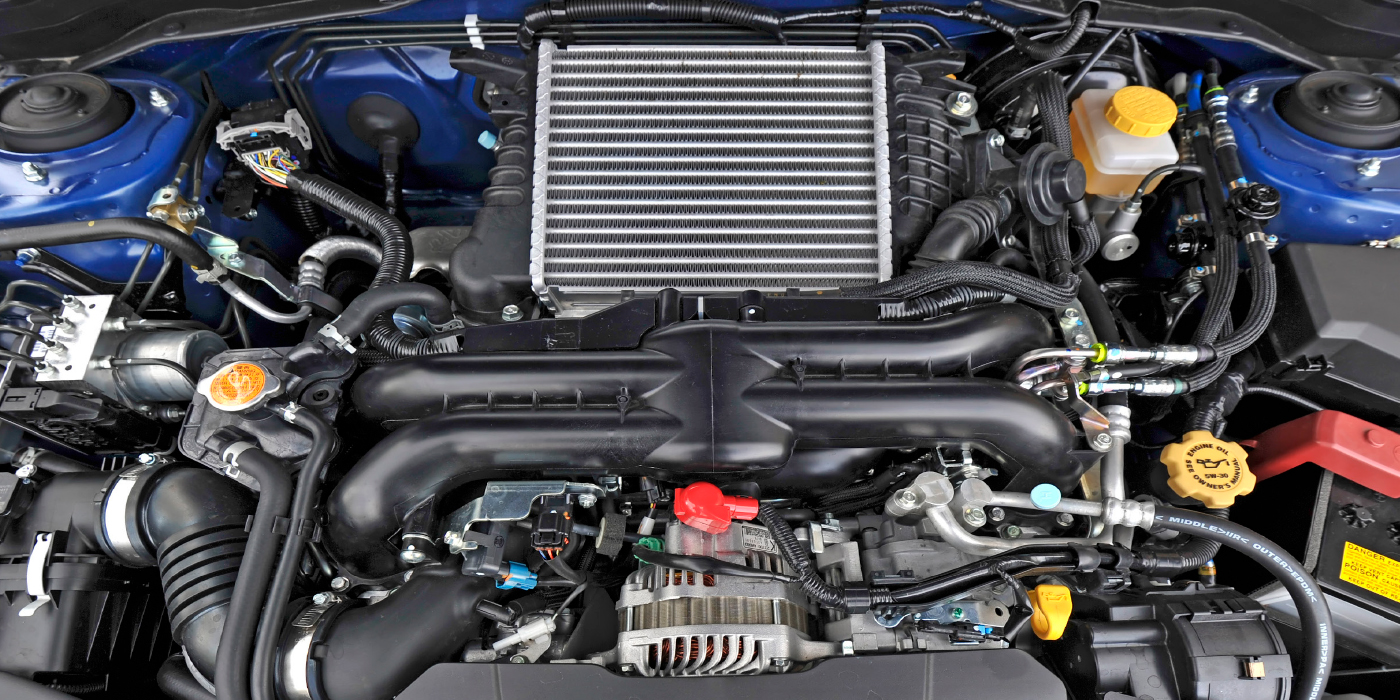

Direct Injection and Turbochargers

Making more power with less displacement puts additional stress on the engine.