Lincoln: Ford: 1998 Mustang

Ford: 1998 Mustang

1998-2000 Crown

Victoria

1998-’99 F-250 LD

1998-2000 Expedition,

F-150

1999-2000 E Series

1998-2000 Town Car

Mercury:

1998-2000 Grand Marquis

Some vehicles equipped with the Romeo-built 4.6L 2V engine may exhibit an engine oil leak or oil weepage from the cylinder head gasket at the right-hand rear or the left-hand front of the engine. Oil weepage is not considered detrimental to engine performance or durability.

An oil leak may be caused by metal chip debris lodged between the head gasket and the block, chip debris between the cylinder head and the head gasket, or by damage to the cylinder head sealing surface that occurred during the manufacturing process.

If an oil leak is verified at the head gasket area, replacement of head gasket and cylinder head can be performed.

Refer to the following Service Tips.

Particular attention must be paid to inspecting the cylinder block for metal chip debris damage on the cylinder head to block mating surface, which may require block replacement.

Service Information

Service Information

A service remanufactured cylinder head assembly is available – P/N XL3Z-6049-AARM (left-hand), XL3Z-6049-BARM (right-hand) containing: cylinder head assembly, cylinder head gasket, cylinder head bolts, rocker arm cover gasket, intake manifold gasket, exhaust manifold gasket, exhaust manifold studs and exhaust manifold nuts.

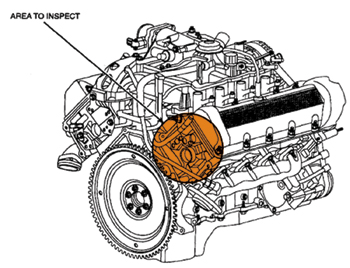

Always verify the origin of an oil leak by using fluorescent dye.

At times, a cam cover gasket or engine oil galley plug (particularly at the rear of the right-hand head) may be the source of the engine oil leak.

See Figure 1.

1998-2000 Head Gasket/ Cylinder Head Replacement Service Tips

1998-2000 Head Gasket/ Cylinder Head Replacement Service Tips

Note: Take extra care not to damage the head gasket sealing surface when performing cylinder head replacement.

The success of the repair is dependent upon following the inspection procedure paying particular attention to the areas depicted in the accompanying figures.

• When cleaning the block deck of residual gasket coating, use Citrus Metal Surface Cleaner (P/N F4AZ-19A536-RA) and a plastic scraper. Wipe with a lint-free shop rag. A shop vac can be used to pick up loose debris/dirt prior to the citrus cleaner application.

Note: Do not use a metal tool of any kind on the gasket sealing surface. Resulting scratches will provide a leak path.

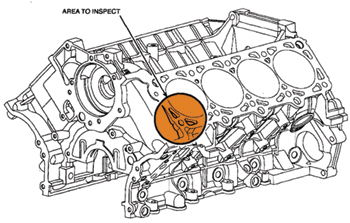

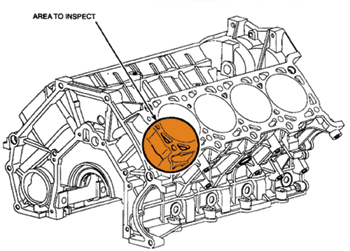

• During normal inspection, pay particular attention to the right bank block deck area behind cylinder #4 or the left bank block deck area in front of cylinder #5 around the oil hole breakout for dimples and impressions left by metal chips.

See Figure 2 and Figure 3.

• The block surface around the cylinder head alignment dowels (two per bank) is another common location for scratches or dimples.

• A known-quality straight edge should be used to ensure the block surface is flat. If a dimple or impression measures over 0.001” (0.025 mm) deep, it is recommended to replace the block. This type of damage is rare.

• If the block does not pass checks, a new or remanufactured long block engine assembly must be ordered.

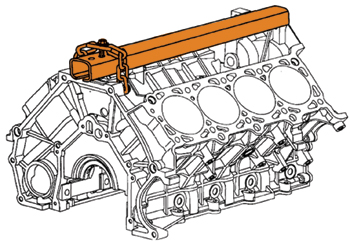

For truck applications, which require use of the Modular Engine Lift Bracket 303-F047 (014-00073) for engine removal, use nine links of 5/16” chain in place of the rear bracket.

See Figure 4.

• As part of the inspection of the block for damage, remove any machining chips that may be in the bottom of the cylinder block bolt bosses. This can be done using a pencil-style magnet.

• After removal of the chip from the block bolt bosses, and if no permanent damage to the block is found, verify that both the block and head sealing surfaces are clean prior to installing the new gasket.

• During installation of the new head gasket(s) and the new cylinder head(s) to the block, lubricate the new head bolts with an oil-soaked rag and allow oil to drip from the bolts, prior to assembly.

Note: Inspect the new cylinder head for damage prior to installation.

Note: The gasket should be placed directly into position and not dragged or moved along the sealing surface to avoid damage. The gasket coating is essential to the function of the gasket. Chips, scrapes or cuts in the surface of the gasket coating may cause the gasket to leak.

Note: Do not apply RTV, copper coat, aviation cement, etc. to the gasket or block/head surfaces. The gasket is to be installed dry. Any foreign material in between the gasket and the head/block may cause the gasket to leak.

Courtesy of Ford Motor Company