Wheel bearings are the connection between the suspension and brakes. When the bearings go bad, the typical wheel bearing job touches both of those critical systems.

The first step, and probably the most important, is inspection of the corner of the vehicle. Since the wheel bearing is part of the brakes and suspension, you need to look at the overall condition of all three. The goal is not to overwhelm the customer, but to make an assessment of condition of the brakes and suspension. It is also important to go for a test drive to confirm the customer’s complaint. Often, tire noise is mistaken for bearing noise.

Service information is vital for writing accurate estimates. But, experience is key in assessing the job to make sure 1.5 hours of labor do not turn into three. Labor times in a guide or for the OEM often are the best-case scenarios with the vehicle specific tools. Check the technical service bulletins (TSB). Wheel bearings often confound OEMs because the warranty labor times can be extremely expensive. Often an OEM will release a TSB regarding new procedures and tools for the wheel bearing replacement after a vehicle has been in the field. Let their loss be your gain.

Know The Load

On a typical passenger vehicle weighing around 3,400 pounds, each pair of front-wheel bearings, as well as the rear-wheel or axle bearings, support around 850 pounds depending on the weight distribution and driveline configuration. If it’s a 6,000-pound SUV, each bearing might carry about 1,500 pounds. This load is concentrated on the relatively small bearing surfaces. These loads do not even take into account the dynamic loads produced by cornering.

The loads that are put on the bearings are called thrust and radial loads. They are the forces the bearings must endure when the vehicle is cornering or braking. Another force that cannot be measured is the force of the impact from potholes and curbs.

In some cases, you will see a vehicle with a wheel bearing failure that is caused by overloading. For some trucks and vans, the owner might be pushing the weight capacity. When a bearing is overloaded, the bearing and rolling elements will run hotter. This damages the grease protecting the bearings. Also, the heat can damage the seal. This can cause the bearing to wear prematurely.

If you see a bearing failure in a component that has been recently replaced, ask the owner how they use their vehicle and what they haul.

Loaded Knuckles

A lot of vehicles manufactured by Ford, VW and Toyota are equipped with cartridge-style wheel bearings that need to be pressed into a knuckle. These bearing jobs can be difficult, even if you leave the knuckle on the vehicle and use special tool to press the bearing.

The latest product to address this job is a “loaded” or complete knuckle that already has a new bearing installed.

Eliminating the need to press the bearing can save time. It can also save you the aggravation from wondering whether or not you pressed in the bearing with the correct seal facing the wheel speed sensor. While you can beat flat rate, you can’t make more hours in the day. Loaded, unitized or complete components can maximize your profitability in the hours your business is open.

CV Joints And Axle Nuts

Many axle nuts are one-time use items. Some nuts destroy themselves when they are backed off the axle shaft. Other nuts have fingers that lock the nut on the axle shaft, but, over time, they lose tension. Many wheel-bearing suppliers are including the axle nut with the bearing kit.

Make sure you are inspecting the CV joint and the shoulders that make contact with the inner race of the wheel bearing. If the surfaces on the axle are damaged or corroded, the vehicle might make a ticking noise that sounds like bad needle bearings inside the joint. The surface can be cleaned up with emery cloth or an abrasive disc. Some OEMs recommend a light coating of anti-seize on the surfaces. Avoid getting anti-seize on the threads or splines.

The most controversial aspect about axle nuts is the use of an impact wrench. An impact should never be used to set the final torque of the axle nut. OEM and bearing manufacturers always recommend using a torque wrench for installation.

Check the service information for the specification and procedures. During removal or running the axle nut down, the impact from the wrench “theoretically” might cause damage to the new bearing or axle shaft because it might be a full droop. Just use common sense when using an impact on an axle nut.

Replacing rear wheel bearings on a live axle rear suspension requires a few extra steps when compared to a unitized bearing. To remove the axle shaft, the differential must be accessed and the clips that hold the axle in the differential must be removed.

Look at the differential cover before you quote the job. On snow-belt vehicles, the differential cover is prone to rust. Perforation does happen, but chances are prying on the weakened cover may distort it to the point that it will never seal. Replacement covers are readily available and very economical.

Servicing The Flange

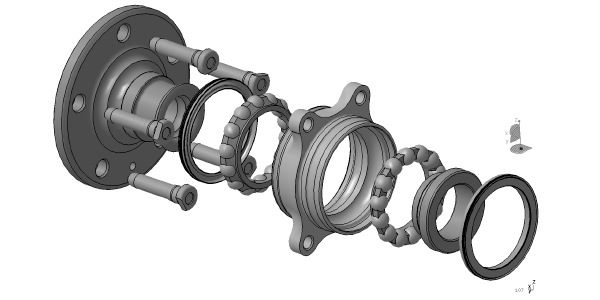

When replacing a press-type wheel bearing and hub flange, it’s important that all the wheel-end parts work together properly after reassembly. Damaged parts or improper torquing can cause premature hub failure and issues with overall vehicle performance.

A hub flange kit contains all the components needed to replace a worn out wheel bearing and flange. It’s best to use a kit that includes the hub flange, cartridge bearing, axle nut, seals and c-clip. Follow proper installation procedure and the steps below to ensure maximum service life for new components.

Parking Brakes

In the case of rear wheel bearings, make sure you are researching the information for the parking brake if the mechanism is in the hat of the rotor. The backing plate that holds the mechanism and shoes is often damaged or rusty. For some applications, aftermarket part suppliers have complete assemblies that just bolt onto the axle or knuckle. This can save you time in assembly and sourcing the parts.

Brakes

Be sure to inspect the brakes, since the caliper has to be removed to replace a wheel bearing. If the pads or rotors are near their wear specifications, recommend replacement. Also, new rotors and new hub flanges should be measured for runout. Indexing the rotor and rotating it on the hub flange for the least amount of runout can compensate for most runout problems.

Fasteners

With more vehicles using aluminum suspension components, more fasteners are torque-to-yield (TTY). Some TTY fasteners can’t be reused. Make sure to check the service information for the torque specs and if the bolt can be reused.

If a ball joint has to be unfastened to service the wheel bearing off the vehicle, look at the shaft. If the shaft has 45-degree taper at the base and not the typical 7 or 10 degree taper, it’s likely to have a very specific torque specification and procedure. These are on components that go into an aluminum knuckle or control arm. These studs are designed to stretch and hold the clamping load. If the nut is too loose or tight, it will damage the aluminum component.

Article courtesy Brake & Front End.