More than 103 million vehicles on the road today have direct TPMS systems. With the average vehicle being more than 10 years old, a vehicle with four TPMS sensors will likely have all of its TPMS sensors replaced during its lifetime.

This is the service opportunity of the decade and you should not let it pass you by. Most sensors will fail outside of the warranty, and the ones that fail inside the warranty will not be because of defects in workmanship. Telling your customer to go somewhere else for a TPMS problem will mean one less customer.

Why Sensors Fail

The No. 1 reason sensors fail is physical damage. Sensors operate in a harsh environment of extreme temperatures and vibration. These forces can damage transmission coils and pressure and temperature sensors.

Another reason sensors fail is due to damage during removal and installation. One false move with a bead breaker or tire iron can break the sensor at the stem. Even forgetting to use a torque wrench or calibrated screwdriver can damage the mounting stem.

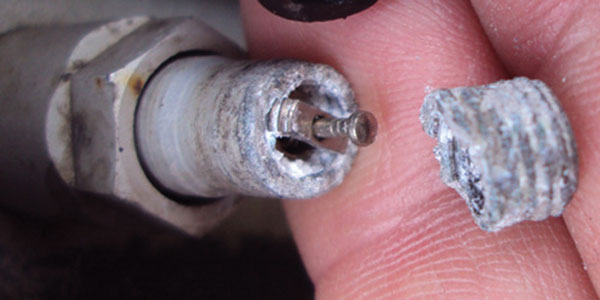

Corrosion is another element that can limit a sensor’s life. The valve stems of some TPMS systems operate in salt, water and ferrous brake dust. These elements can damage a sensor over time. Galvanic corrosion can kill a sensor from the inside. If you use the wrong valve core or nut, it can cause a reaction between the two dissimilar metals. Valve nuts cannot be used twice, not only because of the seal, but because of the coatings on the treads. If you reuse a nut, bare metal on the stem and nut might be exposed, and corrosion could destroy the sensor’s stem.

In the very near future, dead batteries will be the No. 1 killer of TPMS sensors. One sensor manufacturer claims the battery life of a sensor is between three and 10 years, with seven years being the average. Battery life can vary due to the type of vehicle, drive cycle and how long the sensors are awake. Many 2008-’09 domestic and import vehicles with TPMS are nearing the magic seven-year mark when the batteries in the sensors start to die.

On most applications, the battery is sealed inside the TPMS sensor and cannot be replaced separately. If a battery is dead, you have to replace the sensor. It is within reason that if one sensor fails due to the battery, the others should be replaced.

Some sensors even transmit the state of the battery. This information can be accessed with certain scan tools. This number will typically be a percentage. Estimating the life of the sensor can be difficult or impossible due to the various factors that influence sensor life. But, if a customer is replacing a set of tires and the battery life is below 7%, you might want to recommend replacing the sensors at the same time to save the customer the cost of additional mounting, dismounting and reprogramming.

Legalities

For some consumers, a new TPMS sensor may be a tough sell. Some will question the value of replacing a sensor to return a system to working order on an older vehicle. Some will ask if you could just turn off the light so that they can simply check their own tires. This might remind some people of the days when the check engine light appeared on vehicles.

No shop can, or should, disable a TPMS system if it is cost-prohibitive for a customer to replace a sensor. In early 2011, TIA reached out to the National Highway Traffic Safety Administration (NHTSA) regarding scenarios that tire retailers commonly face when servicing vehicles equipped with TPMS. TIA was specifically addressing the so-called “make inoperative” provisions of NHTSA’s TPMS regulations.

Title 49, U.S. Code 30122(b) of the Motor Vehicle Safety Act (MVSA) “prohibits a manufacturer, distributor, dealer or motor vehicle repair business from knowingly making inoperative any part of a device or element of design installed on, or in, a motor vehicle in compliance with an applicable motor vehicle safety standard.”

When this was written, the main concerns were airbags and bumper systems. But TPMS is such a safety system, and therefore, falls under these guidelines. Any professional technician replacing tires needs to be aware of this NHTSA clarification.

According to NHTSA, if the pressure sensor was inoperative before the customer presented the vehicle to the retailer, “A motor vehicle repair business would not be violating 49 USC 30122(b) by removing an inoperative or damaged TPMS sensor and replacing it with a standard snap-in rubber valve stem. However, a motor vehicle repair business that goes on to make any other element of the TPMS system inoperative, for example, by disabling the malfunction indicator lamp, would violate the ‘make inoperative’ provision.”

If a valve stem sensor is not functioning prior to servicing the tires and wheels, then the retailer cannot violate the “make inoperative” provision because the system was already inoperative. This increases the importance of documenting an inoperable TPMS prior to any work being performed on the vehicle, especially now that the batteries in the sensors are starting to die.

Once the driving public thinks that bringing a vehicle to a shop with dead sensors gives them an option to not replace the sensors and substitute standard snap-in valves, this may accelerate a situation whereby vehicles will have inoperative TPMS. This ultimately puts pressure back on the service provider to educate consumers as to the importance of a properly working TPMS.

Article adapted from Import Car.