Transmission fluid likes to be at a constant temperature. If it is too hot or too cold for too long, the performance can fluctuate and potentially cause damage to the transmission.

Transmission fluid likes to be at a constant temperature. If it is too hot or too cold for too long, the performance can fluctuate and potentially cause damage to the transmission.

If the fluid is at a constant temperature, it behaves in a consistent manner in terms of its friction and lubrication properties. What can help control the temperature is the transmission cooling circuit.

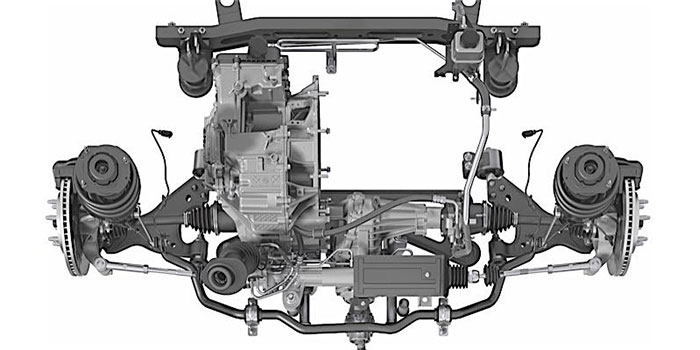

The path of the fluid in the transmission lines is not as much about the destination as the journey. The size and length of the transmission lines, along with the size of the cooler, controls the temperature of the fluid. Also, the size of the engine and weight of the vehicle can determine the design of the transmission fluid cooling circuit.

Another thing to consider is how a modified transmission with a larger transmission cooling circuit might do more damage than good. On modern vehicles, the cooling circuit is designed to manage the fluid temperatures during startup. If the fluid can’t warm up quickly due to the increased volume, damage to the transmission friction surfaces can occur. The same goes for a bypassed cooling circuit. Why? Because fluid that is too hot can damage friction surfaces.

Replacement

Replacement

With the complexities of today’s vehicles, it is always recommended that you replace a transmission oil cooler line with one that matched the original design. Patching or cobbling together a replacement line with a hose can change the thermodynamics of the cooling circuit.

While ATF was designed to operate at temperatures of 175°F, the reality is that transmission and cooling lines are routinely subjected to conditions that cause it to operate at 220° F or more, and up to 300° F intermittently. Essentially, as the heat goes up, assembly life goes down.

Transmission cooler lines are also subjected to high pressure. On older vehicles, 75 to 150 psi is standard. Surges up to 300 psi can be seen on newer electronically controlled transmissions. A small leak under these pressures can lead to serious problems.

It is recommended to always replace fittings when changing a line. If the opportunity to change fittings does not exist, you should make sure you can install new clips, O-rings and washers.

Engine cavitations, road vibration and reduced underhood space can have an effect on your hydraulic hoses.

Flushing Lines

Flushing Lines

If a transmission has failed catastrophically and the vehicle has high miles, it is a good idea to replace the cooler lines.

Cleaning out the cooler is essential for completing a line or transmission replacement. The cooler can hold a large volume of debris in the passages. If the transmission has “grenade,” it might be impossible to backflush all the debris from the cooler. If the transmission cooler is a standalone unit, replacing it might be a good investment to make sure the replacement transmission is not damaged. There are some machines that can backflush the cooler and lines, and some machines can pulse the cleaning fluid to help dislodge debris.

The future of the transmission cooling circuit is getting hot. On some new hybrid and diesel vehicles, the transmission fluid is heated with exhaust gasses. This can help heat the fluid, increase the efficiency of the transmission and reduce wear caused by start-up. Article courtesy Brake & Front End.