The best way to eliminate most oiling related issues is by selecting the right oil pump, oil pan, windage tray, and pickup tube for the application. If you plan to build an engine using the same bearing clearances as the factory, then a stock volume oil pump should be selected. However, if you plan to use larger bearing clearances, then, typically, a high volume oil pump should be chosen.

While most applications – whether stock or performance – use a wet sump system, it should be noted that they have some rpm limitations. There is a physical limit related to rpm on a wet sump, where once that threshold has been crossed, the gears or rotor sets can no longer continue filling with oil, and cavitation will begin. This happens typically somewhere between 6,500 and 7,500 rpm, but may occur at lower or higher rpm levels.

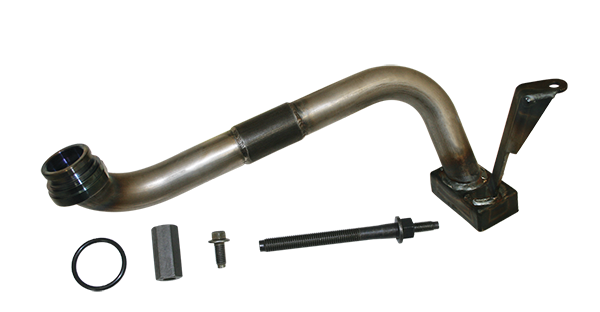

So how do you combat oiling issues such as cavitation and oil starvation? Oil management is the key. You want to keep as much oil as possible in the sump around the end of the pickup tube. A well-designed oil pan and pickup screen is essential. The builder needs to look at the environment the engine is going to be living in. Will the engine see hard acceleration, heavy braking, or hard cornering? All these things need to be taken into consideration when selecting an oil pan and pickup tube assembly.

Our experts say that the oil drain back system needs to be reviewed on older engines. Cale Risinger, technical services manager for Melling Engine Parts, says it is possible to enlarge and smooth the drain back passageways to improve flow back to the sump. “You may also be able to redirect the return path away from the crankshaft to reduce windage.”

Oil delivery to the top of the engine should be inspected because you may be over oiling the valvetrain. We know that LS engines tend to pool oil in the heads. You can install oil restrictors in the oil galleys on some engines if you are over oiling the valvetrain.

Risinger notes that utilizing a vacuum pump with a wet sump pump is not recommended. “Reducing the crankcase pressure will have a negative effect on the oil pump performance. This will reduce the pressure needed to push the oil up the pickup tube and into the pump. As a result, the pump will cavitate at lower engine speeds.”

The reduced crankcase pressure increases the flow of oil through the main and rod bearings, increasing the engine’s demand for oil. For this reason, Risinger says do not modify the pickup tube assembly to restrict the oil flow into the oil pump. Also, he says, do not change the pressure relief in the pump in a way that will restrict the oil returning to the pump’s inlet port during high-speed operation.

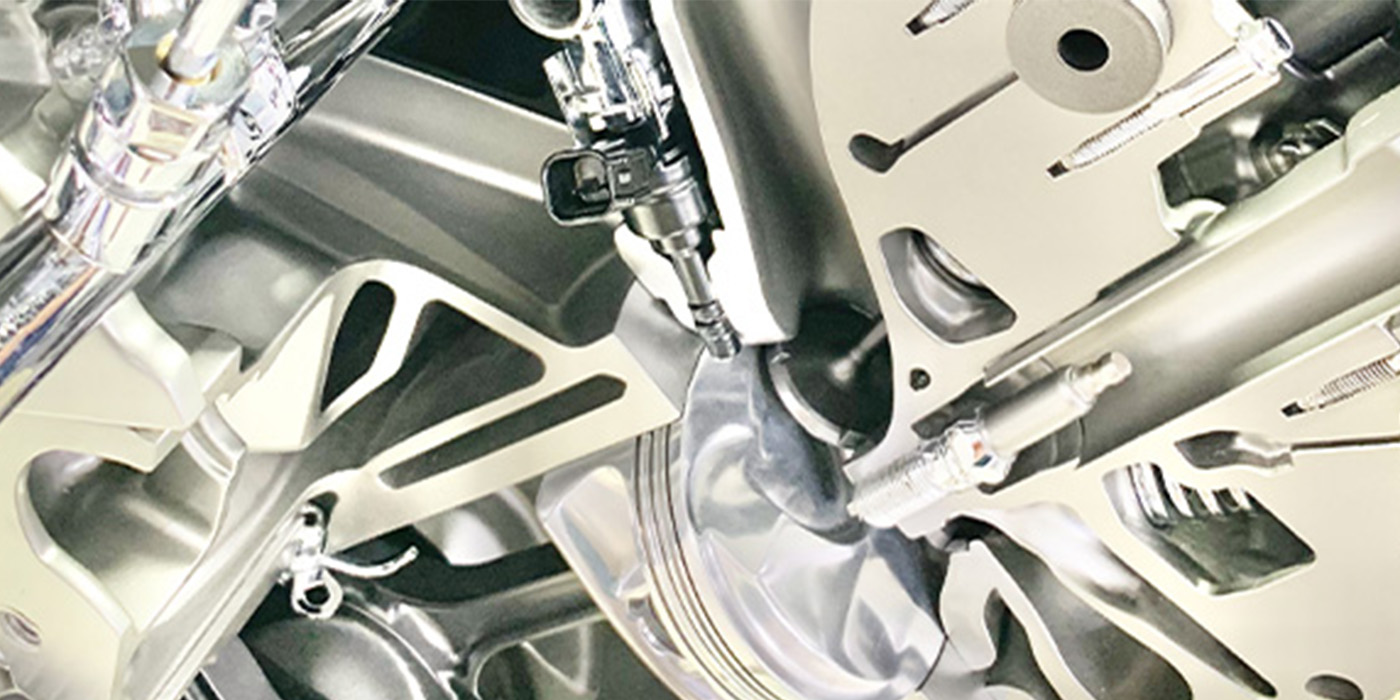

Late-model engines rarely have starvation issues because they are more efficient on the suction side, and many of these applications have block and head designs that improve the return of oil back to the sump. Dedicated oil passageways from the cylinder heads back to the sump and windage trays that cover the entire sump are typical in late-model engines.

The flip side, according to Risinger, is that attention must be given to older engines to improve the oil drain back to assure that oil starvation will not occur. “Oil pump priming is more of an issue with late-model engines as the pickup tube lengths have increased as well as the oil pump’s location changed from in the sump to on the crankshaft. The oil pump is no longer sitting in the oil during cold starts. Due to their design, Melling has improved its late-model pumps’ priming characteristics, but all installers need to be sure to properly prime the oil pump and the engine when starting it for the first time.”

Oil starvation can be a problem on any application, but it’s particularly prevalent on drag race applications. “When the car launches, the pickup can be exposed under hard acceleration,” says Risinger. “You can also have issues with windage at high engine speeds where the crankshaft can keep oil suspended and prevent it from returning to the sump. This is especially true on stroker engines where a well-built crankshaft scraper and oil pan baffling can resolve this issue.”

You may need to increase the oil volume if you make modifications to bearing clearances or run any piston oilers or use thinner oil. “We look at increasing oil flow from the pump if the engine has larger bearing clearances, higher flow rate lifters, adding piston and valve spring oilers,” says Risinger. Modifications that increase the engine’s demand for oil, require a high volume pump.

The most common customer concerns that Melling hears, according to Risinger, is that they either have too much or too little pressure. “We receive calls every day from people saying they put a high-volume pump on and now have 80 psi of hot idle pressure, and over 100 psi at rpm or put a high-pressure pump on and still have low idle pressure. I like to look at the oiling system in an engine as a fixed orifice. If that orifice is large, you need to supply more volume to it to increase the pressure. If that orifice is small, the additional volume will cause high pressure that the pumps internal bypass may not be able to regulate. With this being said, on an engine that has loose bearing clearances, we would want to run a higher volume pump. Standard clearances would get a standard volume pump.

Risinger says high-pressure simply means the pressure that the pump’s internal bypass will attempt to regulate. “A high-pressure pump will not affect low rpm oil pressure. The only way to increase low rpm oil pressure is to decrease the internal clearances in the engine or add more oil volume.”

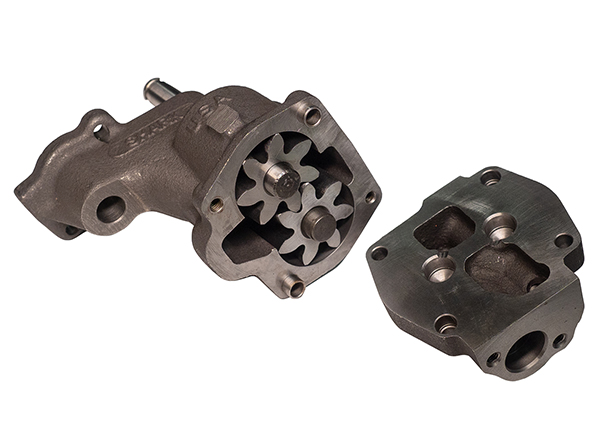

Verne Schumann of Schumann Sales & Service spoke to us about one of his latest oil pumps that is an upgrade to what he calls “old obsolete” pumps. Schumann’s paddle wheel design pump is an upgrade from older SBC pumps. “We can pick up the surface feet per minute and make it competitive with gerotor pumps. We offer them for a small block Chevy, a big block Chevy, and we’ve got Oldsmobile and Pontiac in there as well. And for sure, the small block Chevy, big block Chevy are still serious players.

Schumann says that these new pumps will be his best sellers as they are an inexpensive upgrade. “The whole gist of the idea was to take an obsolete pump, which is a gear-to-gear pump, and now we have a pump that has fast instantaneous reaction time. We are seeing 20%-30% higher gains in gallons per minute with the same size gears. There’s nothing negative. It’s all positive.”

Schumann notes that the paddle wheel is good for about 8-10 hp out of the gate on a crate engine, for example, with more oil instantly. “Where the paddle wheel shines is not at idle, although it helps idle pressure out of idle volume when you take it to drag strip, and the third yellow light comes on, and your foot goes to the floor. You’re just worried about reaction time at that point. With a stock pump or stock valving style pump, it’s designed to do the following: As soon as the oil pressure comes roughly up enough to bypass the internals, where does oil go? As good engine builders know, you have cut off all the oil leaks, and you do not fill the valve covers up anymore. But the oil has to go someplace – the path of least resistance is back down the intake tube.

“So now you’re launching your car on a green light, and your oil pressure is going backward – doesn’t sound too good to me. Our 140 patented process eliminates the reversion of oil going back down the intake tube. It can’t do it, it’s impossible. The reaction time is fantastic with the paddle wheel. No more two, three, or four-second delay where the engine outruns the pump. It keeps up very well.”

Oil Pans

In high rpm engines, the force of the crankshaft spinning can pull the oil out of the sump of the pan and up into the crank. Adding more stroke to an engine can significantly increase windage since the crankshaft throws and counterweights are down closer to the oil in the oil pan.

A well-designed windage tray will, essentially, separate the crankshaft from the oil in the oil pan, helping to eliminate windage. Some very well-built trays will have provisions that help keep the returned oil from the top of the engine away from the crankshaft. A well-designed crank scraper is also essential when trying to address windage issues in these engines.

Melling’s Risinger says that for most applications, a 5-6 quart pan is sufficient. However, more is almost always better when talking about pan capacity. “You also need to keep in mind anything external such as remote coolers or filters that may hold a significant amount of oil. If you are using a cooler that holds 3 quarts of oil you will need to take that into account when filling the system.”

The oil pan design plays an intricate role in the performance of the oiling system. Using a pan that is not designed for the application can cause engine damage or worse. The whole system must work together.

“The oil pan and pickup tube/screen assembly design can both have a huge effect on the oiling system,” Risinger explains. “A poorly designed pan and/or pickup can destroy an engine. An oil pump can only do its job if there is oil available at the pickup tube at all times. This can be a challenge in engines used in racing scenarios due to the forces that are present during hard acceleration, deceleration and high-speed cornering.”

A well-designed oil pan should have provisions such as trap doors, baffles, windage trays, and crank scrappers, says Risinger, to ensure the oil is retained in the pan’s sump where the pickup is located. The screen design is also critical. There are many different screen designs and flow characteristics, as well as racing/performance-style oil pans.

Pro/Cam

Pro/Cam’s unique oval track oil system (pan, pump, and pickup) increases horsepower, reduces temperature, and keeps consistent oil pressure around the track, even in the corners. The company says it is designed to work like a dry sump, with a series of 4 scrapers that help lower oil temperature and keeps the oil light off. The real difference is in the adjustable scrapers, which are adjusted to fit your crank and rod combination. Plus, it features a full-length kick-out. The high volume oil pump and pickup is custom machined and reworked to improve oil flow. Designed for SBC applications with up to 3.75˝ stroke and up to an 8-qt. capacity (plus the lines and filter).

Canton Racing Products

Canton’s high capacity front sump for Ford 332-428FE blocks uses a “T-style” sump to increase capacity without losing ground clearance. It has a 6˝-deep, 12-1/2˝-wide by 10˝-long sump with an 8-quart system capacity. The pan features a slosh baffle, 1/2˝ NPT temperature bung, a provision for a pan mounted dipstick, and a magnetic drain plug.

Moroso

Moroso’s aluminum, dry sump, slopes 5-1/2˝ in front to 6-1/2˝ at the rear of the oil pan is designed for dirt late model and others. The sump is entirely fabricated aluminum with billet end seals to ensure a consistent sealing surface. The large kick-out design frees up horsepower and reduces oil temperature. There are two -12 AN and one -16 AN female pickups, included removable male filter fittings. The oil collection trough with internal runners directs oil to the pickups. An internal rear baffle prevents oil from climbing up the back of the oil pan.

Article Courtesy of Engine Builder.