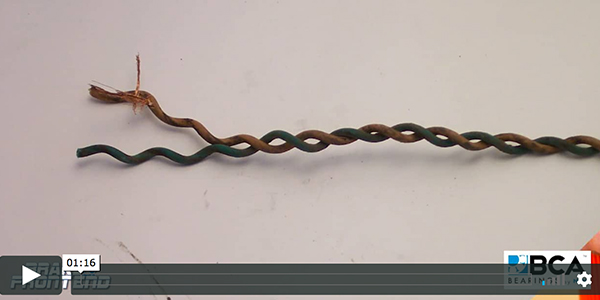

Andrew Markel discusses wheel speed sensors, and how a repair should generally not be attempted on its wiring. Sponsored by BCA Bearings.

Video courtesy Brake & Front End.

Andrew Markel discusses wheel speed sensors, and how a repair should generally not be attempted on its wiring. Sponsored by BCA Bearings.

Video courtesy Brake & Front End.

Over time, the oil filter can collect enough contaminants to become restricted.

With oil life indicators pushing the average oil change past the 7,000-mile mark, it is not just the quality of the oil that’s improved, it is the quality of the filter, as well.

Neglected oil change intervals can ruin the best engine oils and filters. As they accumulate miles, they become contaminated with carbon, water and various acids, all of which are a byproduct of internal combustion that will form a film of black, gooey sludge on the interior parts of the engine.

The key to servicing these systems is proper information and understanding precisely how these systems operate.

Every driver has a different threshold for a pull.

If the clutch gets too hot from excessive slippage or loading, the linings may burn, damaging the clutch.

Accuracy is important for sophisticated ADAS systems.

AWD is always engaged and with the ABS brake modulator, can perform like systems with limited-slip differentials.

The heat eventually burns out the blower motor resistor, and, in many cases, causes the electrical connector to melt.

Here are some tips to follow when replacing a spark plug.

Knowing if and why there’s runout will help you reinstall a smooth braking system.