Andrew Markel reflects on the first time he saw a parking brake cable fail, and stresses the importance of checking on this item during every brake job. Sponsored by Auto Value and Bumper to Bumper.

Did you Know?

• The parking or emergency brake has to perform two distinct jobs. First, it must be able to hold the vehicle on an incline. Second, it must be able to stop a vehicle under a specific distance if the hydraulic brakes have failed. These standards are set by the Department of Transportation, and the kicker is these jobs must be accomplished by the force applied by a little old lady.

• Most modern brake cables have an inner wire that is made of stainless steel and is surrounded by an outer nylon sheath. Some cables have a dry lubricant inside to prevent binding. If you are inspecting brake cables, make sure all of the grommets and boots are in place.

• The best way to keep a brake cable moving freely is to leave it alone. Many home remedies can actually shorten the life of the cable. Lubricants and oils can attract grime that can be pulled into the housing. Solvents sprayed on the cables can wash the grime further into the sheathing and can destroy the cable.

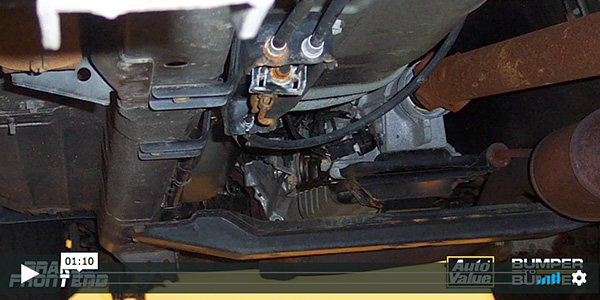

• On most vehicles, the left and right parking brake cables come together and are attached to a lever linkage called an “equalizer” yoke under the vehicle. The equalizer yoke balances, or equalizes, the amount of force that is applied to both cables when the parking brake is engaged. The equalizer linkage, in turn, is connected to a single cable that runs to the parking brake lever or pedal. An adjustment screw may be located on the front cable where it connects to the equalizer, or where the cable attaches to the parking brake lever.

• The equalizer linkage can rust up, interfering with proper application and release. The hinge pivot can also break loose and render the parking brake useless. The typical sign of a worn hinge pivot is normal travel on the lever or pedal, but the parking brake will not hold the car on a hill.

Video courtesy Brake & Front End.