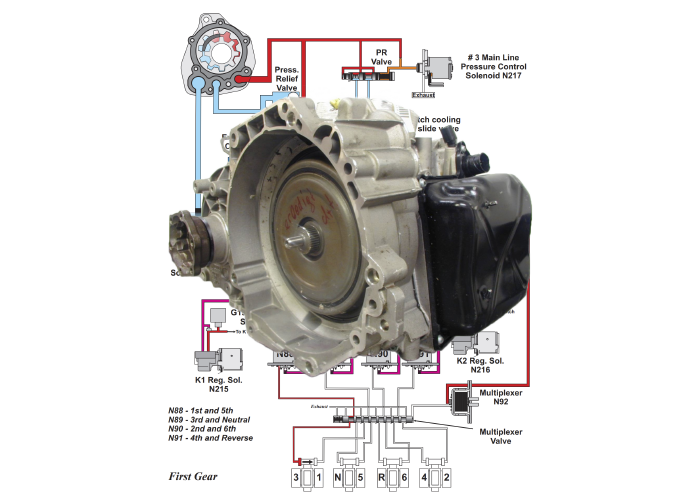

Problems with engine control systems and/or traction control/anti-lock brake systems can have a tremendous negative effect on transmission operation. The VW Direct Shift Gearbox DSG 02E is no different.

This particular transmission is frequently being powered by a diesel engine which adds another dimension to pre-checking the vehicle when there is a transmission malfunction.

The following is a suggested diagnostic pre-checklist when dealing with transmission malfunctions. There is no importance placed on the order of the list.

1. Scan all vehicle systems for codes. Be particularly interested in engine and ABS systems. All four-wheel speed signals must be in perfect order, especially the rear wheel speed sensors. All tire sizes need to be the same. Watch for over-inflated and under-inflated tires as well.

2. Be sure there are no engine vacuum leaks

3. Check EGR valve. Diesel engines produce soot that acts like bad cholesterol in the body clogging arteries.

4. Check the fuel filter for signs of a faulty tandem pump mixing oil with diesel fuel.

5. Check to see if there has been any tuning done that may be malfunctioning.

6. Check the condition of the transmission fluid. Degradations can cause shift and shudder issues.

7. Perform a load test on the battery and check charging voltage and ground circuits. For some vehicles, the negative and positive battery cables become corroded, increasing resistance in the cable itself. This will cause sneaky irritating issues with the electrical systems.

Article courtesy Underhood Service magazine.