Symptoms

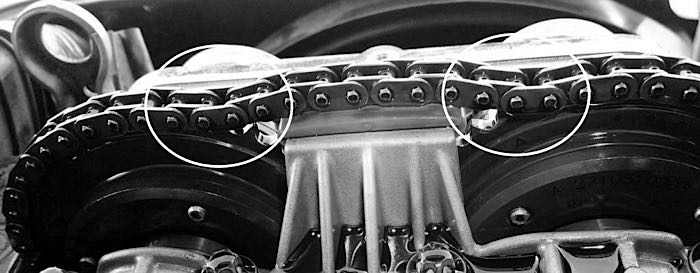

Water pump has missing or broken teeth, or sprocket falls off the shaft.

Probable Cause of Failure

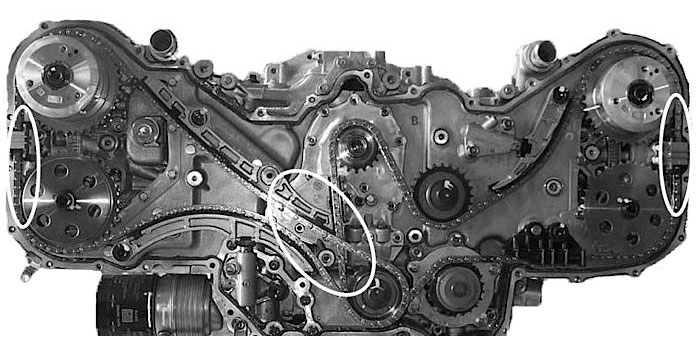

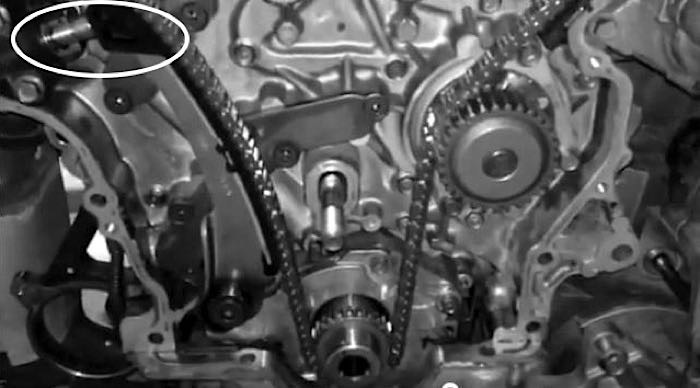

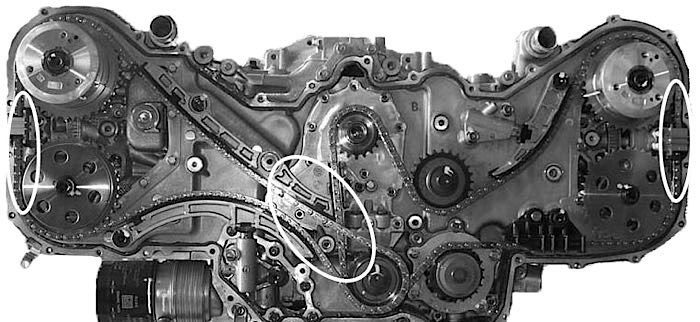

Misalignment or damage of the tensioner, guide or chain.

Corrective Action

Visual inspection is required to verify the correct alignment of chain tensioner and guide. Inspect for broken, cracked or missing guide material as well. It is not advised to reuse misaligned components. Also, check the chain for any imperfections.

Article courtesy Gates.