The control arms on modern vehicles have two primary responsibilities: control and isolation. Vehicle manufacturers put a lot of time and engineering into the shape, construction, and design of control arms. That shape helps to control the suspension geometry as it travels up and down. The bushings inside the control arms help to isolate the passengers inside the vehicle from noise, vibration, and harshness (NVH) which is caused by harsh road surfaces, bumps, potholes, etc.

It’s safe to say that most customers don’t fully understand how important the control arms are to vehicle ride quality, or how other systems can be affected by them when they are worn out. Tires can wear out prematurely because suspension geometry is not being maintained over bumpy roads or going around curves. If a bushing is torn it may cause a knocking or clunking noise.

As industry pros, we understand the importance of many vehicle systems and components (Photo 1). It’s our job to educate our customers on how these systems work, and why they need to be maintained or replaced. We’re going to focus on identifying when control arms need to be replaced, and why they should always be replaced in pairs.

#1: Wear and Tear

Control arms are typically made of aluminum or steel; they are very strong and can take a lot of abuse, but the rubber bushings inside them are not very strong. Over time, the rubber inside the bushings may deteriorate, dry rot, crack or split (Photo 2). When this happens, the bushing will no longer hold the arm in place correctly (Photo 3). Customers may experience abnormal tire wear, excessive NVH, or the steering wheel may appear to be off center while the vehicle is traveling straight down the road.

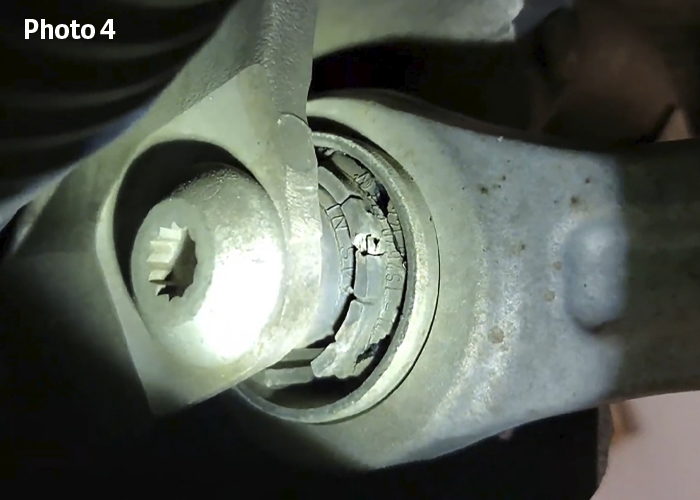

Worn out or torn bushings are the most likely reasons for replacing a control arm, but some will ask “why replace them both”? To me, this is like asking “why should I replace the brake pads on both sides of the car?” If the LH control arm is worn out or the bushing is torn and making noise (Photo 4), it’s safe to assume that the RH control arm bushings are just as worn or following close behind.

Some luxury imports such as Mercedes-Benz and BMW have been using hydraulic bushings for some time now. These bushings will eventually leak the hydraulic fluid out and start making noise. We saw this exact situation unfold on a 2009 BMW 3 Series Coupe. The customer stated that they heard a knocking noise coming from the front of the vehicle when the brakes were applied at low speeds (Photo 5).

As service pros, it doesn’t make sense to take this gamble. How happy do you think your customer might be if they hear the same noise coming from their vehicle a month or two down the road, after they paid you to fix it? And, let’s not forget that any time a control arm is removed or replaced, an alignment needs to be performed on the vehicle. I’ll bet that your customer won’t want to pay for two alignments, so replace both arms at the same time.

#2: Non-Serviceable Components

You may find that some control arms may feature ball joints which are permanently secured into place (Photos 6 & 7). These ball joints typically cannot be replaced separately, so the entire control arm needs to be replaced. The ball joints are critical to vehicle alignment, so these control arms should also be replaced in pairs. Inspect the ball joint boot and look for signs of dry rotting or cracks, as well as leaking grease. And, of course, if the ball joint is loose internally, it must be replaced.

#3: Physical Damage

This may be an extreme example, but if a control arm has been damaged or bent by a severe impact, or a careless tow truck driver, it must be replaced. Photo 8 shows an example of a steel control arm that had been severely damaged from an impact with road debris. Even in a case like this one, it is still best to replace both control arms. You won’t really know what condition the bushings are in on the other control arm, and they will likely perform differently than the bushings inside the newly replaced arm.

Normal Conditions – Do Not Replace

While inspecting control arm bushings, it’s important to be aware of how the bushing should appear if it were new. Photo 9 shows a thrust arm from a Mercedes-Benz. This bushing is not hydraulic and has small voids inside the rubber. These voids are there to help cushion the control arm and isolate the passengers from NVH. This is not a defect, it’s a design feature.

You may also find different types of bushings installed on vehicles which share the same platform. Let’s compare the control arm bushings in a 2017 Golf Alltrack versus a 2018 Audi RS3. These two cars are both build on the Volkswagen MQB platform and share the same control arm, but the bushings are not the same. The RS3 control arm (near the top of Photo 10) has solid bushings for improved road feel and tighter handling. The Alltrack control arm (near the bottom of Photo 10) has bushings which have empty voids in them. This makes the Alltrack ride a bit softer than the sportier RS3.

As always, be sure to check the OE service information if you have any doubts as to what style of bushings are supposed to be installed into the vehicle you’re working on.

So now, if a customer comes into your shop and wants to replace the control arm on one side only, are you prepared to explain to them why it’s best to replace them in pairs?