Turbochargers have been around almost since the first engines were invented. A Swiss engineer named Alfred Büch is often considered the father of the turbo with his 1905 patent for a compound radial engine with an exhaust-driven axial flow turbine and compressor mounted on a common shaft. Early turbos were mostly designed for airplane applications to help them fly at higher altitudes without stalling.about:blank

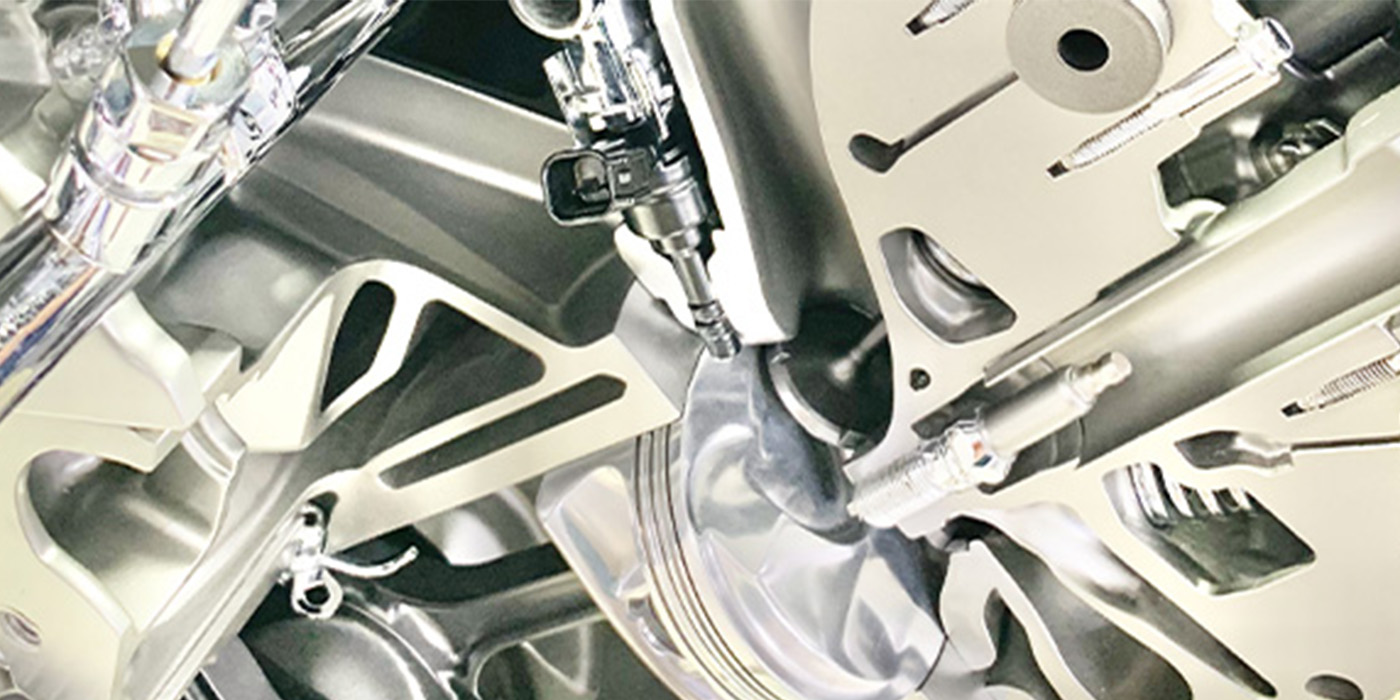

An exhaust-driven turbine wheel spins a compressor wheel to ram more air volume into the intake manifold, producing as much as 25% or more power than a naturally aspirated engine. A turbo improves the engine’s overall thermal efficiency by using waste heat that would otherwise be lost out of the tailpipe.

Turbochargers must “spool up” before they can deliver boost pressure. Peak turbo speeds range from 100,000 rpm to more than 250,000 rpm, depending on the application. But most turbos don’t make much boost pressure below 2,500 rpm. Peak boost pressure on passenger cars is typically between 9 psi to 11 psi, but performance engines run much more boost.

Because a turbo produces more cylinder pressure and heat, the need for following maintenance intervals is critical to the engine’s life. Today’s downsized turbocharged engines require higher-quality lubricants. Synthetic oils or synthetic blends that are “turbo approved” are recommended for turbo applications. Because turbos hold so much heat inside the turbine housing and conduct heat down the shaft into the center housing, oil can get too hot and oxidized and burn.

When mineral-based motor oil is used in a turbo engine, it can break down easier and harm the bearings and center shaft. Oxidized oil can form harmful carbon deposits on the shaft and bearings. The oil-supply lines to the turbo also need to be clear and free from sludge or obstructions. Adequate oil pressure is a must to keep the turbo lubricated. Low oil pressure, lack of oil or aeration can cause lubrication problems for the turbocharger. Consequently, if there is a failure due to lubrication, there is a great deal of labor involved to diagnose the issue to ensure all the oil-supply lines are clear of debris.about:blank

Late-model turbos are equipped with a water-cooled center housing to prevent oil oxidation and overheating. But some vehicles use a timer to allow the engine and turbo to cool before it shuts off. Some applications use an electric pump to keep the coolant flowing until the turbo has cooled sufficiently. If the turbo’s coolant lines are obstructed, or full of air because of a low coolant level, the shaft bearings may overheat.

Heat also may cause the turbine housing to crack and leak if it hasn’t had enough time to cool down. Dirty or clogged air filters can allow dirt and dust to be sucked into the compressor wheel, causing a gradual loss of turbo efficiency and boost pressure. Dirt will act like sandpaper on bearings and the turbine shaft, which will grind away at the clearances and cause a failure.

If the bearings or bushings are worn, the shaft may wobble, creating harmonic vibrations that can make it difficult to spool up and produce boost. Deposits that build up on the shaft or bearings can prevent the turbo from spinning freely. And if the shaft binds up, the turbo may seize altogether. The turbocharger is one of the greatest technologies ever invented, but it’s not immune to failure due to a lack of maintenance. Always remind your customers with turbocharged engines to use high-quality oils and to follow recommended maintenance intervals.

This article courtesy of Counterman.