We’ve all had screws and other fasteners that just refuse to budge. Years of corrosion, heat cycling, and gunk buildup due to weather exposure and normal vehicle operation can literally freeze a screw in place. And we can guarantee the screw head will strip if you use too much force trying to remove it.

But there is a tool that can help you remove those stubborn screws without tears. It’s the manual impact driver, and you probably have one in the back of your tool box. They aren’t expensive, and no other tool can really replicate what it does. Removing just one pesky fastener will convince you of its value.

If it’s been a while since you’ve used an impact driver or have never used one, its operation is simplicity itself. Just stick the appropriate bit in the driver, seat it on the fastener, and give it a few solid whacks with a mallet or hammer. The tool uses that force—up to 200 ft.-lbs. of torque depending on the driver—to turn the bit slightly, like 1/10th of a turn per whack. The impact will also be transmitted through the tool into the fastener just like an ordinary impact gun to shock the fastener loose in the process.

Here’s a testimonial to the value of a manual impact driver. A Summit Racing employee has a 2000 Honda Nighthawk 750 that was stored outside, close to the ocean. During a rehab of the bike, he noticed a few black spots under the kickstand, directly above the drive sprocket—a sure sign of a weeping oil seal.

Removing the sprocket cover revealed the drip was coming from the neutral switch, necessitating a seal replacement. It also revealed that a combination of salt air, chain grease, and road grit had made its way under the cover, corroding the two screws holding the switch in place. Using the correct Japanese Industrial Standard (JIS) bit (more on that below) and probably more force than he should have, our hero managed to remove one screw, but the other one wasn’t having it. He broke out the manual impact driver; a few raps with a hammer and that stubborn screw was sufficiently loosened so a regular screwdriver could remove the screw.

A few words of caution when using a manual impact driver. We totally understand the frustration that comes from dealing with a stubborn fastener, but be careful with that hammer.

On our friend’s Honda, he was dealing with an aluminum transmission case, plus a sprocket and the splined transmission input shaft sitting very close to the neutral switch. One errant hammer blow could have made a bad situation worse.

As good as an impact driver is, there is still a chance you could damage a fastener head during the removal process. It’s good practice to have some replacement fasteners handy; replacing a few is way easier than drilling out a seized one.

Tech Tip: Phillips Head vs. JIS

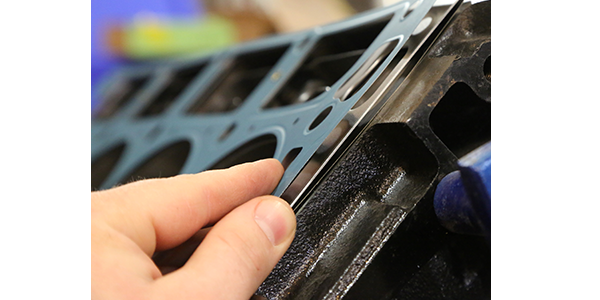

Have you ever come across a machine screw that has what looks like a typical Phillips head, but your Phillips screwdriver or bit doesn’t quite fit? Congratulations, you’ve met a Japanese Industry Standard (JIS) machine screw. JIS screws are found on most every Japanese vehicle made, so chances are good you’ve mangled a few with a regular Phillips screwdriver. The primary difference is in the cross slot on the screw head. A Phillips bit will not completely bottom out in a JIS screw head, which causes the bit to slip, or ‘cam out’. You know what happens next—you apply more force to get the bit to seat and end up stripping the screw head.

Here’s the kicker—JIS bits work just fine for Phillips head screws.

The moral of the story? Add some JIS screwdrivers or driver bits to your tool box and put the screw-stripping days behind you.

This article is sponsored by Summit Racing Equipment.