What You Need to Know About Mercedes-Benz Maintenance

With new vehicle sales topping 17.8 million units, and import nameplate VIO also on the rise, you’ll be seeing more imports that are in need of repair. And, with the increasing complexity and interconnectivity of vehicle systems, diagnostic expertise becomes all the more important. With that said, we bring you this collection of Mercedes-Benz repair tips to aid your service efforts.

1. W211 Rear Air Springs

The 2003-’09 E-Class (W211) is known for leaking rear springs. With these Mercedes repairs, the rear springs on some AIRMATIC suspensions can be labor-intensive to replace, while others are as easy as replacing a strut. The springs mount to the lower control arm and the sub-frame. Leaks typically occur where the clamps hold the springs to the upper and lower caps. To replace the springs for this, you’ll need to lower the rear subframe. This Mercedes-Benz repair requires the removal of the exhaust system, driveshaft and parking brake components to be able to access the air bags and reservoirs. Some aftermarket replacement air bags have been engineered to eliminate the separate reservoir. This eliminates another component that can cause leaks down the road.

2. No Shift, Transmission Lever Won’t Come Out of Park, And Other Shifter Faults

One common Mercedes-Benz maintenance problem in a number of late-model M-Bs is a situation where the transmission lever won’t move, the key won’t crank the engine, or the car won’t move, even though the shifter moves freely.

On automatic transmission models, there is no “shift linkage.” The transmission is controlled electronically on most models built in the last 15 years. On some models, there is a cable going to the ignition switch, but the connection to the transmission is by wire. If you get a number of codes during this particular Mercedes-Benz repair related to the shift module (N15/3 or N15/5) or transmission range switch, look closely at the shifter/console and see if a “gremlin” has been released in the form of spilled coffee, juice or water from the sunroof being open the last time it rained.

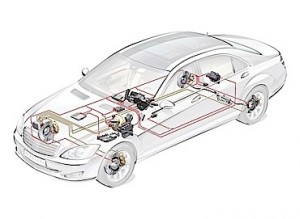

3. ABS And/Or ASC Fault Codes

On ML series cars (SUVs), a problem that occurs quite frequently is in the wiring near the windshield washer bottle. For these Mercedes repairs, corrosion in the connections at the ABS module can cause a number of codes relating to the ABS and the traction control system. Of course, there are also potential Mercedes-Benz repair problems with any wiring that has been attacked either by living or environmental forces (see Photo 1). Visual inspections should be your first diagnostic step whenever an electrical problem is suspected.

4. Dead Battery And Low Suspension

If a problematic AIRMATIC suspension comes into your shop (one that is dead or intermittently leaving the vehicle on its bump stops), one of the first things to check for this Mercedes-Benz repair is the high-amperage fuse for the compressor. The relay can fail on either the “on” or “off” position. If it fails in the “on” position, the fuse will blow. If it fails in the “off” position, the fuse will not blow. On these Mercedes repairs, the relay has a bad habit of getting stuck in the “on” position. This will lead to a dead battery and maybe even a worn compressor. This will also damage the relay. The system will force the extra pressure out of the bypass valve and exhaust hose, and the owner may notice that the compressor running and hear a hissing noise coming from the front of the vehicle. In some cases with this Mercedes-Benz maintenance opportunity, the compressor will be damaged from it constantly running.

5. No Heat at Idle

If you get a Mercedes-Benz repair coming in with a complaint of poor heater performance, it might require deeper diagnostics. The driver says on cold mornings the heater will blow cold during the long drive to work in rush-hour traffic. The car is not overheating and the air is coming from the correct ducts. The culprit might be the auxiliary water pump. The auxiliary coolant pump should provide enough volume of coolant to keep the heater core warm.

Mercedes then started to use these pumps on gasoline-powered vehicles like the C- and S-Class for the same purpose. This allows vehicle engineers to use larger heater cores to provide better passenger comfort in the cabin.

New technologies like hybrid drives and stop/start systems need auxiliary pumps to not only improve driver comfort, but also to keep the batteries at a constant temperature.

A failed pump will almost never cause the vehicle to overheat. If the auxiliary coolant pump is inoperative, the customer might notice reduced heater performance at low speeds and at idle.

Your first instinct with this Mercedes-Benz repair might be to replace the thermostat, the water pump or the heater core, but if the vehicle is equipped with an auxiliary coolant pump, you will need to dig a little bit deeper.

The main reason why these pumps fail is due to age and wear of the electric motor. Like all rotating electrical devices, brushes wear and windings short. Overheating can hasten the electric pump’s failure and lead to necessary Mercedes repairs because increased cooling system pressures can force coolant past the shaft seals. Low coolant can also cause a pump to fail because of its position, which is typically high in the system, either on the firewall or strut tower. Keep in mind, most Mercedes-Benz vehicles produced after 1999 have these auxiliary coolant pumps, including everything from the C-Class to the S-Class. If you are having trouble with this Mercedes-Benz maintenance problem, you not only have to troubleshoot the pump, but also the system that controls it.

6. Alternator/Battery Light Codes

On 2003-’05 C230 1.8L, 2003 CLK320 3.2L, 2006 C230 2.5L and 2007 CLK550 5.5L models, the customer may come to you with the “visit workshop” warning message for the alternator. Conventional diagnostics might have you running for the battery tester and voltmeter. But, the best tool for initial diagnostics with this Mercedes-Benz repair is a scan tool because the alternator is a connector to the ECU and the output is monitored by modules on the LIN bus.

If the vehicle has DTC P2062, it typically indicates the alternator or regulator is faulty or the output is too low. If DTC 2061 is set, it could indicate a problem with the alternator’s serial interface and the presence of an electrical or mechanical fault. Default operation of the alternator when the LIN bus fails is 14.3 volts. The ECU will send a signal for circuit 61 operation over the engine CAN bus or via signal line to the Signal Activation Module (SAM). With these Mercedes repairs, be aware that some rebuilt alternators are not rebuilt with OEM-quality components.

Tests/Procedures:

- Connect an alternator tester to the vehicle and test the alternator’s output amps and voltage.

- Perform a battery load test.

- Remove and inspect the brush set for sticking brushes. Inspect wiring on the back of the alternator for damage.

- Use a scan tool to perform guided tests. This alternator is internally regulated and is connected by a LIN bus to the PCM so that the regulation control can be intervened.

- Verify Battery Positive Voltage (B+) at the battery connection on the alternator; verify that it has a good connection. Some engines will have an in-line fuse from the starter to the alternator.

- Test the wiring for a signal line between the engine control unit and the front SAM, if applicable. (Courtesy of Identifix)

7. Communication Errors and the Immobilizer

With Mercedes-Benz maintenance, the most common pattern failures for communication problems are wiring faults. Caused by corrosion, insulation failure or abrasions, this has been a long-standing problem. One of the best diagnostic tools at the onset of communication with this Mercedes-Benz repair is your own eyes. Look for any signs of repaired or unsecured harnesses. Obvious signs of abraded wire loom or exposed wires (rodent damage) can be a clue to a system failure. What might seem to be unrelated could be a part of a no-start condition, especially on cars with CAN communications.

Immobilizer codes are always difficult for a small shop to diagnose for these Mercedes repairs without the equipment required to access the onboard systems necessary to reset or re-enable the Drive Authorization System (DAS). There are a number of different TSBs for various models, but one of the first things to try is always going to be another key for the vehicle. Also, a dead battery can cause the alarm system to disable the DAS.

8. Long Service Intervals on High-Mileage Mercedes

Shops found that a lot of the running problems with high-mileage Mercedes are due to extended service intervals. Plugged air filters, deteriorated breather or vacuum hoses, and contaminated MAF sensors are always possible culprits when confronted with high-mileage Mercedes-Benz repair. Removing the plastic engine cover may be all that’s necessary to spot a broken breather hose or disconnected vacuum hose.

For these Mercedes repairs, pull a spark plug to get an idea of its condition, looking for obviously worn plugs. This also helps you get a picture of the “mixture” based on their condition. A misfire can have a significant impact on fuel trim, even without setting a misfire code. An obviously rich condition could indicate a leaking injector or fuel pressure problems.

9. AIRMATIC Suspension Riding High

Most AIRMATIC systems use accelerometers mounted on or near the shock towers. These sensors are designed to detect body movement and sudden impacts that are found on rough roads. If the accelerometers detect rough conditions, the ride height will be increased. When these sensors go bad, they will generate codes C1121-C1123. If an accelerometer has failed, it might cause the system to raise the suspension to the highest ride height.

10. Brake Bulbs Cause ABS Problems on Sprinter Vans

Always check to see that the ABS and Stability Control Systems are functioning when the Mercedes-Benz repair in question pertains to Sprinter vans. Most Sprinters have ABS and some level of traction control as standard, while some are equipped with optional stability and rollover mitigation systems. Not repairing the system for this type of Mercedes-Benz maintenance opportunity can put the driver in jeopardy due to the vehicle’s high center of gravity. If the ABS light is on, ask for diagnostic time to resolve the problem.

In TSB 08-028-06, Mercedes-Benz states that a burned out or incorrect type brake light bulb could result in unrelated DTCs in the ECM or ABS/ESP control module. Also, corrosion in the trailer tow connector, as well as on a taillight circuit board, may cause similar erroneous and/or unrelated DTCs.

When confronted with unexplained DTCs that affect various modules, a technician should perform some preliminary checks to diagnose the condition before conducting any Mercedes repairs. Check all brake light bulbs and verify that they are of the correct type (P21/5W – 12V 21/5W). The brake and park light are part of the same bulb. An incorrect type bulb may bridge these two circuits. With this Mercedes-Benz repair, you need to ensure that there are no broken filaments, the sockets are free of any corrosion, and there are no bent connectors or conductors.

Courtesy ImportCar.