s where the “builder” will pull a spark plug wire to confirm they have spark. This is one of the most misleading tests for the ignition system. If the spark plug produces a spark, the spark is at 14.6 psi (normal air pressure at sea level), not 170 psi or more inside the cylinder during the top of the power stroke.

The spark test will only tell you that the ignition system has control and can send power to the primary side of the coil. You could have confirmed this with a meter, scope or scan tool. The test does not verify the condition of the coil output with an out-of-cylinder test. The test makes for great TV drama, but has little diagnostic value and could damage an ignition coil.

Understanding Coils

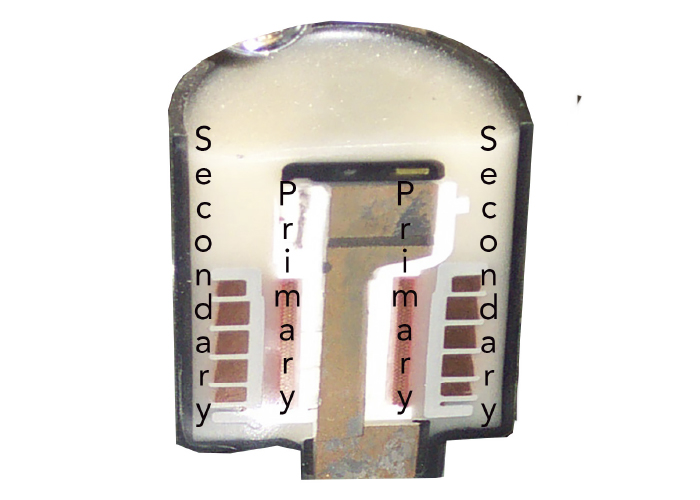

Can an ignition coil degrade? This is a difficult question to answer. Degrading implies that the output of the coil is reduced. But an ignition coil has no moving parts. It is just windings of copper wire suspended in epoxy. Also, some coils may have the trigger circuit mounted inside. But, having a coil lose output due to something inside is rare.

What does cause a coil to fail are the circuits in the primary and secondary. On the primary side, it could be a bad power or ground. It could also be how the power is switched on and off. For the secondary, the output of the windings can be the connection from the coil to the spark plug. Also, the spark plug’s condition can cause the spark’s output to degrade.

In the past, ignition coils were oil-filled, and the secondary and primary windings were separated by bake-a-lite, wood and eventually plastic resins. It was always possible that the coil could leak from the coil and heat would damage the windings, causing a low-energy spark. But, the most common symptom was always the sudden failure of the coil and the loss of spark.

Modern Coil Construction

Modern ignition coils use epoxy resin instead of oil. While the resin does not have the same thermal properties as oil, it is more durable. Like oil, the resin’s dielectric properties separate the primary and secondary coils electrically. While the epoxy won’t leak from the coil, it can be damaged by heat and vibration.

What can cause a coil to degrade is not inside; it is the connection to the secondary. The output of the secondary is channeled through the boot or ignition wire to the spark plugs.

Testing the Entire Ignition Circuit

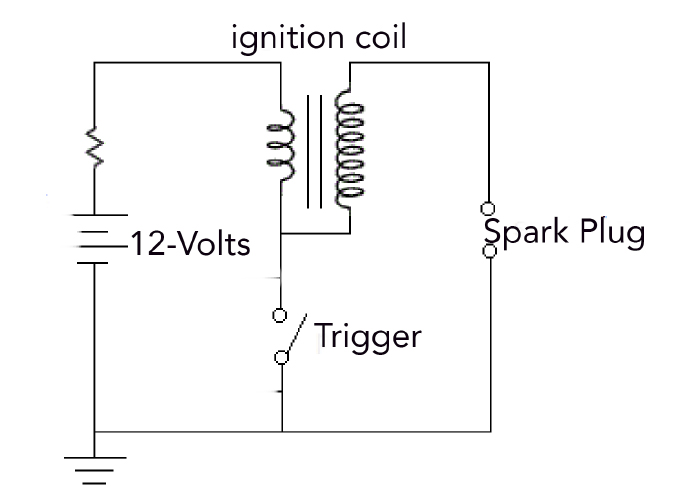

The ignition system is a circuit. On one end, you have a transistor (or points) that turns power on and off. At the bottom of the wiring diagram, you have the gap between the electrodes of the spark plug. In between, you have the primary and secondary windings of the coil.

One of the best ways to test the condition and output of a coil is by using a capacitive probe to measure the secondary ignition waveform. If you can’t find a “known good” waveform, compare the waveform to another coil on the engine. To test the primary side of the coil, you can use a current probe placed around the positive wire going to the coil. With this test, you can see if the power is being sent to the coil and if the engine management system controls the coil by the current ramp.

If you look at a secondary ignition waveform on a scope, you will see a spike representing the coil’s output. I know what you are thinking: if the ignition coil has a fixed ratio of primary and secondary windings, and the system voltage is constant, shouldn’t the spike always be the same? In theory, yes. In practice, the spark plug and mixture of air and fuel inside the cylinder can determine how high the spike will go on your scope.

Do not remove the coil’s connector while the engine runs to see if a misfire or rough-running condition changes. Some OEMs advise the connector should never be removed if the key is in the “on” position.

Your first tool for diagnosing an ignition issue is your eyes. Spend time inspecting the coil’s connector, boot and the spark plug. Often, the cause of an ignition system problem will be present.

The key with the spike and sparkline is to compare it to the other coils on the vehicle. If one spike goes higher than the rest, it signifies two things. First, the resistance in the combustion chamber could be different than the rest of the cylinders, or the spark plug could be worn. If the spike is significantly lower than the rest of the cylinders, it is a sign that the resistance is lower in the plug or cylinder. Sometimes, a clogged or dead fuel injector can cause a lower spike when the throttle is snapped.

Why Coils Fail

What kills ignition coils is location, as they are mounted in one of the hottest, most vibration-prone and dirtiest parts of the engine. Modern ignition coils are typically located between two camshafts on the valve cover and exposed to dirt and oil. But, even if a coil is mounted in a cool, clean and vibration-free environment, if the gap on the spark plug is not correct or there are issues with high resistance in the cylinder, it won’t take long for a coil to fail.

The windings in the primary and secondary eventually break down, and, hopefully, the primary and secondary turn into an open circuit. The worst-case scenario is the voltage from the secondary finds its way into the primary and eventually the driver for the coil. This is why you don’t swap coils to diagnose a misfire code.

Some problems stem from the condition of the spark plug well. When the power from the secondary is traveling through the boot, ignition wire and spark plug, it creates static electricity that causes oil and dust in the area to stick to the component. You have probably seen this condition on spark plugs where the ceramic insulator is exposed on the side of a head. The spark plug can have a yellow or orange band called a corona stain. Some technicians mistake it for exhaust gases leaking between the shell and insulator. If enough material builds up on a boot or plug, it can create a path of least resistance for the electricity generated by the secondary.