The most labor-intensive seal to replace on any engine is the rear main seal. There are no shortcuts or quick fixes if the seal has expired. On most modern engines, the seal’s failure is due to a condition inside the engine or a component connected to the back of the engine.

Solving why the seal failed in the first place is critical to preventing a labor-intensive comeback. Here are six questions you should be asking yourself before, during and after a rear main seal job.

Is it the rear main seal that is leaking?

It might not be. On most engines, oil leaks can occur above and below the rear main seal. It could be a leaking oil pressure sensor, oil pan gasket or galley plug near the seal that causes oil to come from the bell housing. Adding dye to the oil can help reveal where the oil is coming from.

Is the PCV system clogged or blocked?

Most rear main seals have a lip that rides on the shaft. The pressure inside the crankcase will push the lip onto the shaft. Too much pressure will eventually cause the lip to balloon and allow oil to pass.

If the Positive Crankcase Ventilation (PCV) system is blocked, it will increase the pressures inside the crankshaft and push out the seal. Also, if the engine is supercharged or turbocharged, excessive blowby due to worn or damaged piston rings can cause increased crankcase pressure that can also damage the rear main seal.

What is the condition of the oil?

Most oils have chemicals in their additive packages that will condition the seals in the engine. If the oil is not changed regularly, it will cause the seal to degrade.

The seal conditions are depleted over time along with buffers in the oil. The lip that rides on the crankshaft will become stiff and will not be able to seal itself against the crankshaft.

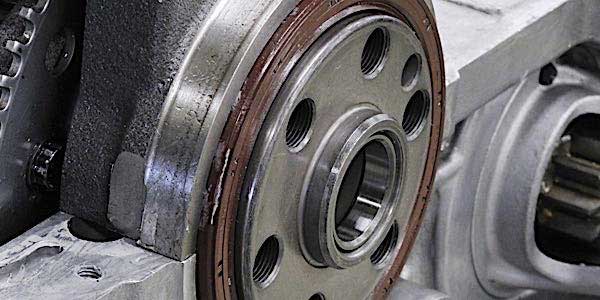

What is the condition of the crankshaft?

The condition of the surfaces that the rear main seal rides on is critical. Any imperfections or wear on the crankshaft can cause a leak. There are sleeve kits that can be installed on the crankshaft to restore the surface.

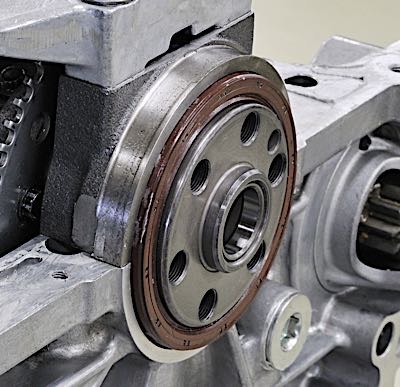

Did you follow the directions that came with the seal?

Some rear main seals need to be installed dry. These seals have a polytetrafluoroethylene (PTFE) coating on the lip seal that needs to be dry and seat to a dry surface on the crankshaft. The seal will transfer a layer of PTFE to the crankshaft surfaces that the lip will ride on. The transfer layer prevents wear while sealing better than a silicone or Viton material.

If the seal is installed with a coating of oil, it will start to leak in a few miles.

Are there alignment issues?

If there are any alignment problems with the bell housing or input shaft of the transmission, they can cause stress on the rear main seal. Make sure you check the input shaft on a manual transmission for play. On vehicles with automatic transmissions, check the flex plate for lateral runout or damage. Article courtesy Underhood Service.