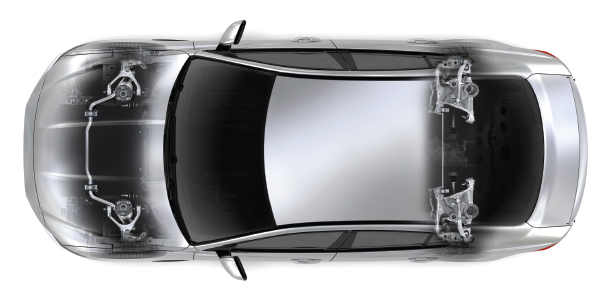

From Audi to Toyota, import nameplate manufacturers are using more aluminum for suspension components. An aluminum component is as strong or stronger than steel or cast iron but what sets aluminum apart is how it fails. Most aluminum suspension components are extruded or forged. If an aluminum component has undergone extreme stress, such as a curb strike, the part will most likely crack and break instead of bend.

If you have a vehicle in your bay that has been in a crash or has had a curb strike, look for cracks. There are dye kits on the market to help you inspect for issues. These kits are easy to use and can spot unseen cracks.

Never try to weld or heat aluminum suspension components. Aluminum is more heat sensitive than iron or steel. The heat from welding can ruin the temper of a component and make it more brittle.

When inspecting a vehicle with aluminum control arms, pay special attention to the ball joints. Almost every stock aluminum control arm uses plastic or composite materials for the socket insert instead of a hardened metal socket. This is due to fretting corrosion where the two dissimilar metals wear and tear away at each other under loads and stress.

FASTENERS

Aluminum components may require special fasteners and tightening procedures to make sure they keep their tension and do not damage components. Typically, you will see coated threads, threadlockers and torque-to-yield (TTY) fasteners.

TTY fasteners are mounting fasteners which are torqued beyond the state of elasticity, and therefore, undergo plastic transformation, causing them to become permanently elongated.

Conventional ball joints and tie-rod ends use a tapered stud and hole with a nut on top to secure the stud to the knuckle. The 7-10º angled taper, along with a threaded stud and nut, locks the components together by tensioning the nut and stud.

The first vehicles to use TTY studs had aluminum knuckles, such as those seen on the Audi, BMW and Jaguar applications. Now these types of ball joints and tie-rod ends can be found on VWs, Hondas and Subarus.

The metallurgy and heat treatment of TTY bolts and regular bolts is different. TTY ball joints and studs have an inset hex head at the end of the stud. This can be used when tightening to the specified torque and setting the torque angle.

Aluminum knuckles, upper control arms and ball joints can be damaged if not tightened using the correct procedure. Knuckles and upper control arms are aluminum and can be damaged if a torque wrench and torque angle gauge are not used.

Many ball joints may have an initial torque spec as low as 15-30 ft.-lbs. and torque angles are between 140º and 225º. Never guess or try to use your calibrated elbow; always look up the spec and use a torque wrench. The same procedure is also required for tie-rod ends. Make sure the washers on the studs are in good condition and installed in the right direction. If a washer splits or fails, it could cause a catastrophic failure.

THREAD LOCKERS

On some aluminum suspension components, automakers are using chemical thread lockers. These substances fill in the spaces between the male and female threads and harden into a tough plastic that locks the entire fastener in place. This not only prevents vibration loosening, but also seals out moisture, dirt and other contaminants that can cause corrosion and compromise the integrity of the suspension.

Courtesy of Brake & Front End.