Carbon deposits have been around since the dawn of the internal combustion engine. For European makes, carbon deposit problems always become more frequent as new fuel systems and engine technology are introduced. In the 1980s, new fuel injection systems and EGR valves caused many TSBs to be released on carbon deposits. Today, direct injection or GDI, variable valve timing and turbocharging are causing new bulletins to be issued.

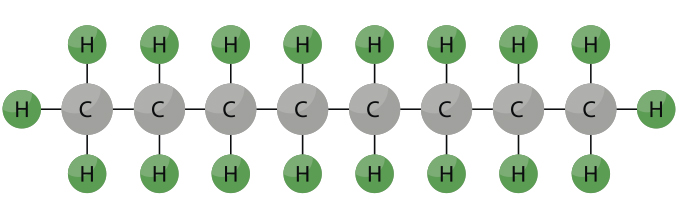

What is a carbon deposit? Visually, a carbon deposit looks like a black clump attached to engine parts like pistons, valves and cylinder head ports. Chemically, a carbon deposit is a twisted assembly of carbon chains that latch onto each other. These carbon chains have an affinity for each other and form strong bonds. The carbon chains are basically mutilated oil and gasoline carbon chains that have not fully been broken down during the combustion process.

Is it the design of the engine?

Yes and no. For direct-injected engines, the fuel injector is after the valve. Fuel and added detergents are not hitting the back of the intake valves. By injecting the fuel directly into the cylinder instead of at the back of the valve, the gasoline and detergents can’t clean the valve and port.

The other factor with carbon deposits and engine design is the turbulence of the air entering the cylinder. If you look at some European engines, the air will travel through an intake that can change runner length and flaps positioned before passing the intake valve. The goal is to control the turbulence of the air entering the combustion chamber.

If there is a malfunction, the air entering the combustion chamber can become turbulent. These rough air pockets can cause fuel droplets to coalesce in the combustion chamber. Larger fuel droplets do not burn the same as smaller droplets. This can cause unburned fuel and increase the potential for carbon deposits.

Is it the software?

Yes. Leaner mixtures and higher combustion pressures can make carbon deposits worse over time. A direct fuel-injection motor produces more energy from a given amount of fuel and air than a port fuel-injection engine. Today’s engines operate on the edge between optimal efficiency and a misfire. There is little room for errors like hot spots in the combustion chamber or a worn spark plug.

When a hot spot or sub-optimal flame front is created due to turbulent air, the amount of unburned fuel in the combustion chamber increases. When the valve opens during the intake stroke, it might come in contact with these byproducts, and, unlike the exhaust valve, the gases passing by are not hot enough to burn it off.

Updating the engine management software is one of the most effective methods for preventing a carbon buildup problem. New software can reduce carbon deposits by reducing the exposure of the valves to conditions that cause carbon buildup through the adjustment of valve and spark timing.

Don’t assume that you will find a TSB stating that a reflash of the ECM will correct a carbon buildup problem because most regular updates may never say anything about a problem. You may even have to check the OEM’s website to see if the vehicle has the latest software version.

Is it the valves?

The intake valve goes into the combustion chamber, regardless of whether it is port fuel injected or direct injected. When it does, for that small period, it is exposed to combustion byproducts that can stick to the neck of the valve. If the last combustion cycle is less than optimal, the intake valve is exposed.

Some direct-injection vehicles with variable valve timing can expose the valve to combustion byproducts as the valves adjust, which creates a scavenging effect to either pull or leave behind a small amount of exhaust gas in the chamber to control NOx emissions. Also, some turbocharged direct-injection engines will leave the intake and exhaust valves open at the same time to keep the turbo spinning to reduce lag.

Valve designs have also changed. Some valves use a sodium metal core to help with the transfer of heat. Some new valves use advanced coatings and surface finishes that prevent adhesion of the carbon deposits.

Why are some direct- injection engines more prone to deposits?

If you look up direct-injection carbon deposit problems on the Internet, engines from BMW, Audi and VW consistently rank the highest. Engines from GM and Ford that have been on the road for at least four years hardly have a carbon deposit complaint. What’s the deal?

Some direct-injection engines can have unique timing cycles that can increase compression, temperatures and exposure of the valves to the combustion chamber.

The modern engine typically has variable valve timing and even cylinder deactivation. The engine management system can control when, how long and, in some cases, how deep the valve goes into the combustion chamber. If an intake valve is dropping into a combustion chamber with combustion byproducts or unburned fuel, the valve might be exposed to the precursors that cause carbon buildup.

Some carbon deposit problems are amplified due to the positive crankcase ventilation (PCV) systems. The crankcase vapors can leave an oily film on the intake valve that is then baked into carbon. Some blame the valve overlap during the intake stroke, which eliminates the need for an EGR valve.

What does oil have to do with carbon deposits?

One of the earliest oil tests was the NOACK test. The test involves heating a sample of oil and measuring what is left over. The more sludge or carbon that is left over, the higher the volatility number.

Most conventional oils have high volatility numbers, meaning they vaporize more quickly when exposed to heat. The high number means that the oil can become thicker over time and won’t lubricate as well. It also means that there is a greater volume of oil vapor in the PCV system that has to be processed.

These vapors can be loaded with hydrocarbons and stick to the intake valves, causing a carbon deposit problem. Synthetic oils have much lower oil volatility, reducing the amount of oil vapor and the possibility of carbon deposits forming on the intake valves, piston crown or intake manifold.

When a piston travels up and down in the cylinder, oil is splashed onto the walls of the cylinder. Although the majority of the oil is scraped away from the walls by the oil control piston ring, some oil remains in the small cross-hatch finish of the walls. Also, the oil can become trapped in the compression rings.

The oil can be burned in the combustion chamber or catalytic converter. The smaller the droplet of oil, the greater the chance it will be burned. The larger the droplet or volume of oil, the greater the chance the oil could add energy to the combustion processes that ignite at the wrong time. The oil can also cause carbon deposits.

Oil trapped in the rings and on the walls can act like diesel fuel that ignites when compressed. Also, think of hot spots in the combustion chamber as glow plugs. If the right conditions exist, the burning of the oil can occur long before the top dead center. This phenomenon is called pre-ignition and can cause cylinder pressures to spike. Pre-ignition and the resulting spike can cause misfires and even damage to the piston, connecting rod and crankshaft.

A direct-injected engine increases the chances of pre-ignition because of elevated compression ratios and leaner air/fuel ratios that make for higher combustion temperatures. The other factor is how late-model engines are managed or tuned. Modern engines are designed to make most of their power at lower engine speeds. At these lower crankshaft speeds, the engine uses less air and requires less fuel. But, that is also the sweet spot for pre-ignition. GM calls it Low-Speed Pre-Ignition or LSPI.

Additives in the oil can cause pre-ignition or at least increase the probability of an event. Some oil companies report that oils with high levels of detergent promote LSPI. Detergents and friction modifiers can help prevent LSPI. GF-6 oils help to address this problem. Many automakers, including BMW, VW and Mercedes, have introduced new oil standards.

The oil in the crankcase of a direct fuel-injected or turbocharged engine can make a huge difference in the health and performance of the engine.

Recently, many manufacturers have recommended specific oil grades that meet proprietary requirements. These are not to be ignored if you are changing the oil on a direct-injection or turbocharged engine. The oil is not magic. Oil is a mixture of additives and base stock, components tuned for specific characteristics. For modern engines, the two most important characteristics are volatility in the crankcase and what happens if the oil is burned in the combustion chamber.

What about soot?

On some gasoline direct-injection engines, the amount of soot particulates generated by the combustion process is more significant than with port-injected engines. This is due to how fuel droplets burn inside the combustion chamber.

These soot particles can find their way into the engine oil. While one soot particle will not cause wear, clumps of soot particles will cause abrasive wear. Additives in oil can keep the soot particles in suspension so they can’t clump together. Soot can also cause oil to sludge.

More advanced engine technology is coming to your shop soon. Variable displacement, compound turbochargers and hybrid port/direct fuel systems are on the roads. New technologies can make more power out of a precisely measured amount of fuel and air. These changes mean more stress and the possibility of carbon deposits and engine damage.

Another new technology being used by Porsche and Audi is the use of a gasoline particulate filter. Just like a diesel particulate filter, the filter traps soot particles so they can be eliminated during a regeneration cycle.

What is the fix?

The most important fix is preventive maintenance. Scheduled oil changes and air filter performance can keep the engine running how the engineers intend and prevent the formation of deposits. High-quality oils with lower volatility can reduce the volume of vapors in the crankcase.

In-tank fuel injector cleaners can also help injectors maintain the correct spray pattern. This can ensure that the droplets have the correct size and distribution during ignition. In addition, extra detergent can help to break down deposits. Induction cleaning products and systems can put solvents and detergents onto the back of the intake and in the combustion chambers. These two maintenance services can help reduce carbon buildup and possibly avoid having to take more drastic measures like blasting the valves with walnut shells.

In many late-model cars and SUVs, the base 1.4L engine is able to make 20% more power with 20% less displacement when compared to bigger engines from a decade ago. Gains in power and fuel economy have been realized with direct injection and turbocharging.

However, making more power with less displacement puts more stress on the engine, causing them to evolve and experience problems like carbon deposits.