If you have ever driven a car or truck with a fully locked differential around a tight corner or tried to get a car with an open differential out of a snowbank, you know about the benefits of a limited-slip differential.

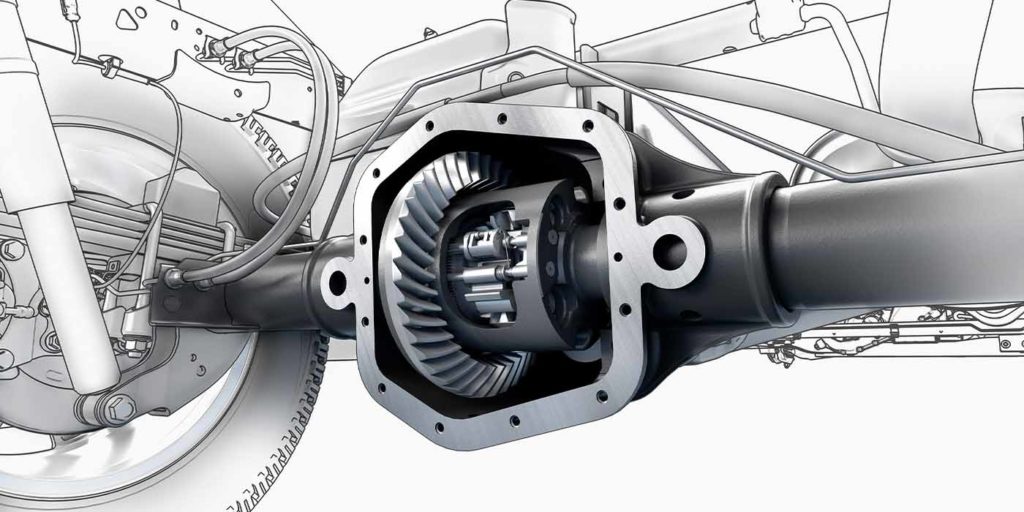

A differential allows the two connected wheels to spin at different rates. The two wheels are connected using spider gears. If the spider gears do not spin on their axis, the two axle shafts spin at the same rate. If the spider gears start to spin, the axles spin at different speeds. How the direction of the rotation changes and which axle is spinning faster determines which one gets the most power.

The ring gear produces radial forces. The changing speeds of the axles produce tangential forces on the spider gears. A tangential force can be caused by different rates of the wheels going around a corner or when torque is applied to the differential (the “one-wheel peel”). A limited-slip differential helps to control the tangential forces, so the radial forces produced by the pinion and ring gear are transferred to the wheel that needs the power. There are several differential designs you might see in the field.

Open Differentials

As the names imply, these differentials just have spider gears in the differential. These differentials let the wheels spin at different rates when going around a corner. These gears in the carrier need to be splash lubricated by the ring gear. The level of the lubricant housing is critical.

Clutch Pack or Cone Differentials

The most common style of limited-slip differential uses clutch packs on both sides of the carrier to limit the movement of the spider gears. If a wheel starts to spin and increase torque-induced tangential forces, a ramp or cone applies pressure to the clutch pack to lock the carrier and axle.

For these differentials to work properly, the condition of the fluid and additive package is critical. Some of these differentials require special fluid or you have to add a small amount of friction modifier.

Torsen Differentials

A Torsen differential is a geared differential that uses four to six or more worm gears attached to spur gears. As torque is applied to the gears, they are pushed against the walls of the differential housing, creating friction. The friction resists the relative movement of the axle shafts. This locks or distributes the torque to the wheels on an axle. These can be found on performance cars and off-road trucks.

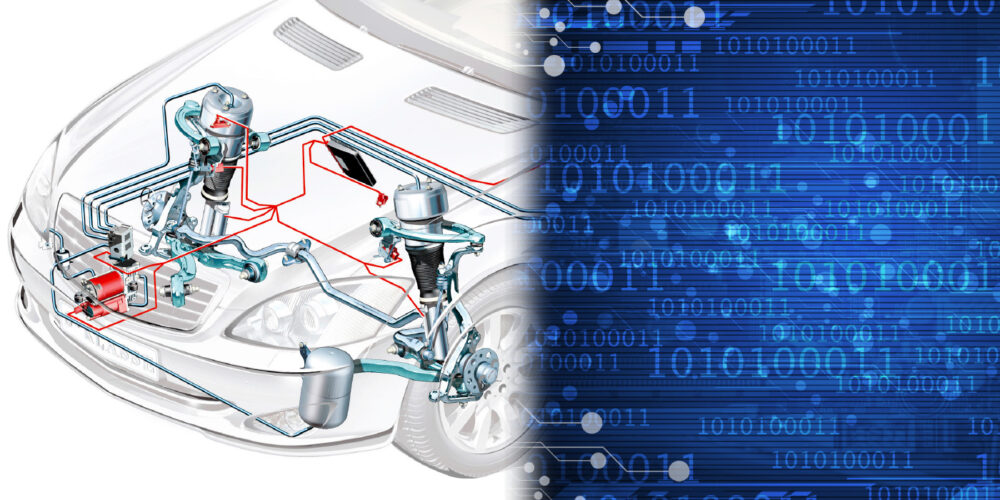

Electronic Differentials

Some automakers are using the ABS system to control the differences in speed of the wheels on an axle. This can make an open differential act like a limited-slip differential under certain conditions. By pulsing or locking the brakes on one corner, it can send power to the opposite side of the differential. This works well at low speeds. With this system, the brakes can be used to free a wheel from a slippery ditch or eliminate torque steer.

Some SUVs and performance all-wheel-drive cars and trucks are utilizing what looks like a locked differential, but the system has clutch packs on the sides of the differential. The clutch packs can lock or completely disconnect a driveshaft. It can even do the “holy grail” of differentials, torque vectoring.

The torque-vectoring differentials can control the amount of power going to each wheel connected to the axle using hydraulics or electric solenoids. Some high-horsepower front-wheel-drive vehicles have a basic torque-vectoring differential (such as the Ford Fiesta RS) to control torque steer.

Torque-vectoring differentials can work together with the stability control system and PCM to maximize traction during acceleration. It can be used during off-road and on-road situations at a wide range of speeds. The main inputs are the steering-position sensor and yaw sensor. The differential control module makes corrections by determining where the driver wants to go and where the vehicle is going to make a correction.

This rear differential can control the power to the rear wheels. These differentials can act like a locking, limited-slip or open differential with only a change of the electronically controlled clutches.

Torque-vectoring differentials have another advantage – they can disconnect a drive axle better than any locking hub. Decoupling an axle with clutch packs reduces rotating mass in the driveline and increases fuel mileage. The system then will decouple the center differential. On some vehicles, the driveshaft can be uncoupled from both the transmission and rear/front differential. This decoupling of the driveline can reduce rotating mass and load on the engine. This is all performed in milliseconds, and the driver does not feel even the slightest vibration.

Article courtesy BRAKE & FRONT END.