Ex’Splining’ New Wheel Bearing Designs

From an engineer’s perspective, wheel bearing design and selection can be a balancing act between durability, cost and fuel economy.

How Noise, Vibration & Harshness Diagnostics Is Changing

The topic of noise, vibration and harshness (NVH) diagnostics came home to me 20 years ago when I began dabbling in collector car repairs. Customers soon began complaining about wind noise and chassis vibrations in ’60s-era cars. Back then, these complaints weren’t repairable because good NVH abatement technology had yet to be developed. Today, that is not the case.

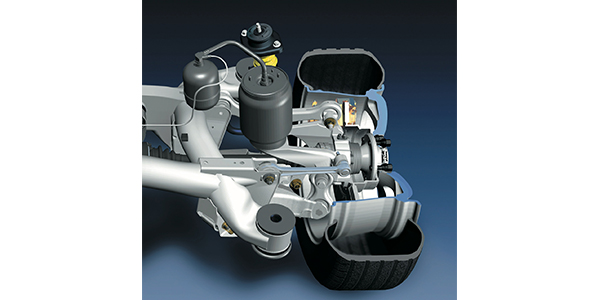

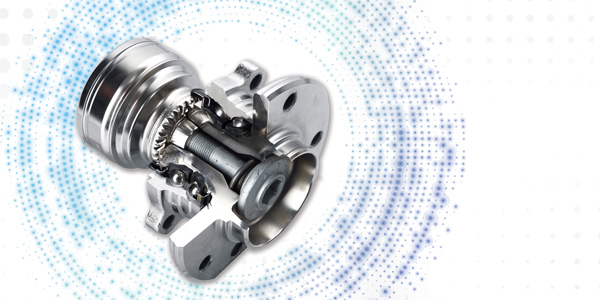

New Wheel Bearing Technology Will Change Your Replacement & Diagnostic Approach

Two technologies are now being used on new vehicles and in aftermarket replacement hub units that allow engineers to put better bearings in smaller packages. These technologies will change the way you replace and diagnose wheel bearings.

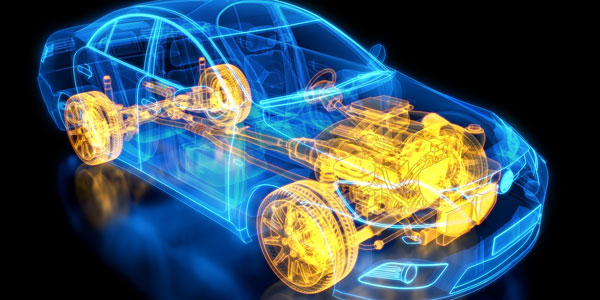

How To Diagnose NVH Complaints In Drivetrain Components

Thanks to advanced technology, modern vehicles operate with fewer noise, vibration and harshness (NVH) complaints than ever before. Consequently, when a NVH issue arises, it’s most likely caused by worn drivetrain components like universal joints, constant velocity joints or wheel bearing hub assemblies. In any case, NVH complaints can often be the most challenging to diagnose when you can’t duplicate the driving conditions under which they occur.

Common Reasons For Wheel Bearing Failure

When a bearing wears out, it is usually a case of inadequate lubrication, faulty installation or improper adjustment. For the repair to be successful, you must first determine why the previous bearing failed. For sealed hub units, examining the internal bearings and races is impossible.

Impact Damage On Wheel Hubs

When a driver hits a pothole or curb hard enough, extreme forces are put onto the balls or rollers and races of the bearing. This can result in the formation of a very small mark on the surfaces. The driver might go 1,000 miles or more before these components start making noise.

Wheel Bearings: Diagnostics, Removal And Installation

The classic symptom of a bad wheel bearing is typically a cyclic chirping, squealing or growling noise that changes in proportion to vehicle speed.

Spring Is Pothole And Bearing Season

The classic symptom of a bad wheel bearing is typically a cyclic chirping, squealing or growling noise that changes in proportion to vehicle speed. The sound may only appear or disappear at certain speeds. The noise may get worse when turning, or it may disappear momentarily. So, it’s difficult to make a diagnosis based on noise alone.

Torque And Runout: Measure Twice, Install Once

There are two critical measurements when installing a modern hub unit or cartridge bearing: torque and runout in the flange. Ignoring these critical numbers to save time will only lead to more comebacks and angry customers.

Drivetrain Noises & Wheel Bearing Replacement

Some of the toughest challenges import specialist techs face are noise complaints. And, in order to make an accurate assessment, we take the time to ask our customers questions like: Is the noise present when the car’s stationary or moving? Does it change around corners or under different load considerations? Is it a growl, squeak, groan or rattle?