We all know that customers don’t always speak the same language as us. They may come into your shop saying that their vehicle “doesn’t sound right,” but they can’t give you any more details. In these moments, we need to try to coax out whatever information they might have, even if they don’t realize how helpful they can be. This can be challenging for techs, but not impossible.

Here’s an example: “Customer states their steering doesn’t feel right.” After performing a road test, you notice that the steering wheel doesn’t want to return to center after completing a turn. This is a sign of memory steer. While it is not a common issue with modern suspension and steering systems, it can still occur and can be really challenging to diagnose. So, how do you recognize when a vehicle is exhibiting signs of memory steer, and what can cause it?

What is Memory Steer?

Memory steer is a phenomenon in which the steering wheel doesn’t want to return to center after going around a turn. Or, the vehicle may exhibit a moderate to severe pull in one direction after completing a turn. Finally, the driver will feel as if they constantly need to make steering corrections in order to keep the vehicle driving straight ahead. This is commonly referred to as “wandering steering.”

We know that the steering wheel should want to return to center when turned in either direction, thanks to the caster angle. While you and I know this, and we know why it works, our customers likely can’t say the same. They simply expect the wheel to return to center because it always has before. So, if their vehicle starts to exhibit signs of memory steer, it can really catch them off guard.

What Causes Memory Steer?

We can summarize the cause of memory steer in one word: binding. There are a number of suspension and steering components that can cause memory steer if they are worn out or faulty, but the task of diagnosing exactly which component is at fault can be a difficult one.

In a typical MacPherson strut setup, the strut assembly contains the strut, the coil spring, the bearing and the upper mount. There aren’t a lot of areas in the strut assembly which could cause a memory steer condition.

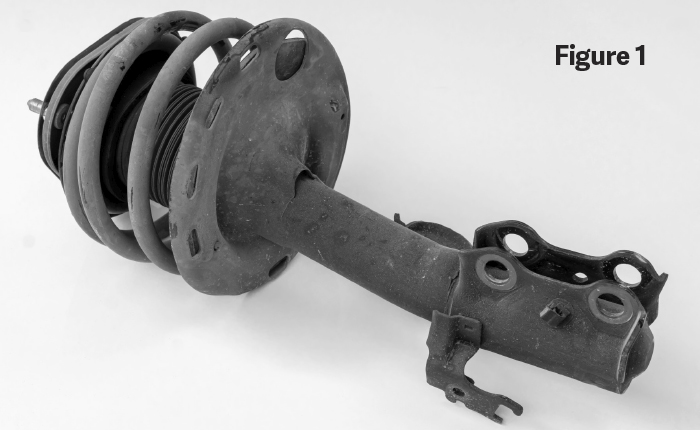

Some technicians may be fooled into thinking that the strut rod may have been bent by some form of abuse, or impact from a collision (Figure 1). However, this is highly unlikely since the strut rod is extremely strong. If your customer is complaining of memory steer on a vehicle equipped with MacPherson struts, the bearing underneath the upper mount is a much more likely suspect.

Since the upper mount is affixed inside the strut tower, the strut assembly needs to rotate on the bearing whenever the wheel is turned. As the vehicle ages, the bearing ages as well. Over time, water, salt, and debris will find their way inside the bearing shell and displace the grease from inside. This can cause the bearing to wear out rather quickly, causing it to freeze or lock up. Once this happens, the strut assembly won’t pivot freely anymore, and the steering wheel won’t return to center as it once did.

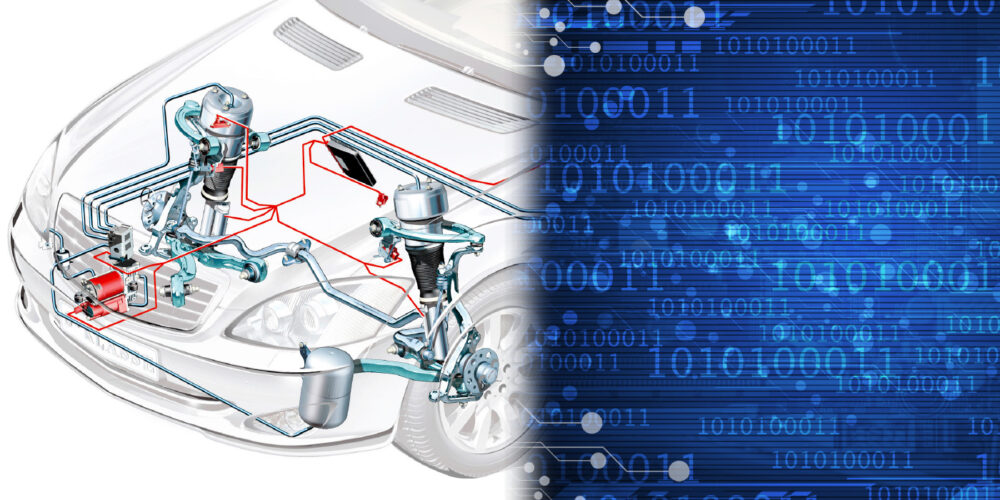

Next, let’s talk about solid front axles which are found in heavy-duty trucks. There are two components which can cause memory steer in solid front axles: the ball joints and the front axle U-joints. The ball joints can be damaged due to improper installation or handling, causing them to bind up while rotating the knuckle. This is why it is so important to always use the proper tooling whenever pressing in new ball joints. The tooling must always support the mounting flange, not the ball socket or housing (Figure 2). If the outer U-joints on the front axles start to freeze or bind up, you may notice signs of memory steer or wandering steering.

Tips & Tricks

Here are a few tricks to add to your toolbox. If you’re working on a truck with a solid front axle, and you want to pinpoint the source of a wandering steering complaint, lift the truck, and remove the front wheels. Disconnect the steering linkage and the sway bar from both sides of the truck, then pivot the knuckle back and forth by hand. Next, rotate the brake rotor 90° and pivot the knuckle again. If the knuckle binds up in either direction, the outer axle shaft U-joint is most likely the culprit.

If you’re working on a vehicle with MacPherson struts, lift the vehicle and remove the front wheels. Disconnect the tie rod end and the sway bar from the knuckle, then rotate the strut assembly back and forth by hand. Listen for the sound of a growling bearing, and if you can feel any binding or grinding transferring through the strut assembly, the bearing is the likely suspect in this case.

Don’t Be Fooled By Steering Bind

Finally, let’s talk about a related issue, but one which is not the same as memory steer. That issue is known as power steering bind. As the name suggests, this occurs when the steering wheel becomes difficult or impossible to rotate during a turn. This concern is often misdiagnosed due to the number of components which could be to blame, but we’re going to tell you how to narrow it down.

If the wheel binds up with the engine at idle, rev the engine up to 1500-2000 rpm and try again. Doing this will increase the output from the power steering pump, and that added hydraulic pressure should be able to overcome any mechanical binding coming from the steering shaft U-joints. If the steering is still binding up with the engine at 1500-2000 rpm, this points to something outside of the steering column. If there is a steering shaft between the column and the pinion on the rack or gear box, try disconnecting it and see if the u-joints move freely.

Remember that a binding ball joint, steering gearbox, or faulty steering linkage would still cause the steering wheel to bind, regardless of hydraulic pressure.