Article courtesy IMPORTCAR.

When a Subaru customer complains that the air conditioning is not operating the way it should, the first tools out of the toolbox after a test drive might be a thermometer or a set of A/C gauges. However, these tools can only tell you so much. On some more modern Subaru vehicles, you might be better off grabbing your scan tool.

Back in the day, it took Subaru drivers a while to find the optimal positions for the fan speed, door and temperature positions. Automatic Temperature Control (ATC) has made finding constant comfort in a car a lot easier.

ATC systems require a complex array of internal and external sensors that include ambient air temperature sensors, interior temperature sensors and evaporator temperature sensors, pressure sensors, humidity sensors, blend door position sensors and sun load sensors. Things get even more complicated when it is a dual-zone ATC system.

Temperature Sensors

To maintain a preset air temperature, an HVAC system will typically have one or more interior air temperature sensors, an ambient (outside) air temperature sensor, and one or two sun load sensors. Subaru also uses a temperature sensor after the evaporator.

Interior air temperature sensors are usually simple, two-wire thermistors that change resistance with temperature. These use a small electric fan for the same purpose. A plugged aspirator tube or inoperative fan will slow the sensor’s response to temperature changes.

Subaru ambient air temperature sensors typically have a slow sample rate to even out variations in readings that may be sensed at different vehicle speeds. When the vehicle stops moving, heat can build up quickly around the sensor behind the bumper and mislead the ATC module into thinking it’s getting hotter outside. Most ATC modules only look at the ambient sensor input every couple of minutes instead of continuously. On some applications, the ATC module may even ignore inputs from the ambient sensor when the vehicle is not moving.

All the sensors work together to keep the driver and passenger comfortable, and work together with the ECM to keep the operation as economical as possible.

Solar Load Sensors

ATC systems also make use of a photodiode sun load sensor on the dash. This sensor allows the ATC system to increase cooling capability when the cabin is heated by sunlight. The system will increase blower speeds or even go into recirculation mode.

Door Actuators and Sensors

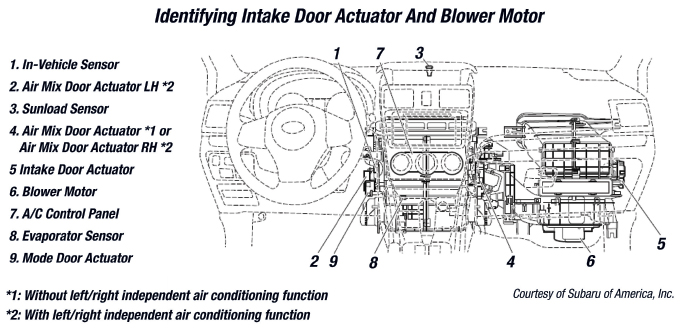

To channel the air to the ducts, most late-model Subarus have four or five doors, actuators and position sensors. The doors control the flow of air through the inlet, evaporator/heater core cases and eventually to the ducts. The position of the doors depends on the selected position on the control head and the ATC system.

The actuators are controlled by the HVAC head unit that is a module. The actuator has a potentiometer inside the housing to measure the position of the door. The potentiometer sensors are supplied with five-volts – as the sensors move, the resistance changes the signal voltage.

Blower Motor

According to TSB 10-96-19, 2012-2018 Forrester, Impreza and Legacy models may have an issue with the original blower motor. Water could enter into the blower motor casing and cause damage. On ATC systems the blower will stop working; on manual systems, the blower motor might only work on full speed. Subaru has introduced improved blower motor assemblies. Aftermarket blower assemblies did not have the problem in the first place.

Even an adequately charged Subaru A/C system can bring cooling complaints from the customer. The issue might not be under the hood. If you are checking duct temperatures, you may notice fluctuation. The changes might be the ATC working to regulate temperatures. But you still need to check for codes in the HVAC system. The fluctuations could be caused by a faulty ambient or evaporator temperature sensor. This is why you need a scan tool.