No matter where you look, change is happening in the automotive industry. There are so many forces at work to change tomorrow’s automobile. With all of these forces deciding if a vehicle will run on electricity, fossil fuels, hydrogen or pixie dust, let’s also add to the mix if a driver will be driving. Will we get to the autonomous vehicle that we keep hearing about? Will supply chains determine the direction or the availability of materials and what country provides them?

Where we’re going and where we end up could be two totally different places. The real question is, what does the customer want? What sells? No matter what drives the industry or where we go on this journey, there is one factor that will always be there: people break and wreck stuff. We’re all thankful for that as we are the automotive repair industry and we fix what gets broken.

How we fix what customers break is changing too. Over the years, we’ve seen the equipment we use to repair vehicles change — plastic welders or new repair processes for all those bumper cover repairs to squeeze-type resistance spot welders and MIG welders to meet all the requirements of the new steels and aluminums. We’ve seen new improvements in these welders, but the task is, in theory, the same. There are also new glue pulling techniques for steel and aluminum vehicles, all changing the way an industry has operated for decades.

The introduction of advanced driver-assistance systems (ADAS) components in vehicles has also changed our thought process for repairs and created the need for new scan tools, software and targets. The process is still the same, but the tools have improved.

OE vs. Aftermarket

Vehicle manufacturers obviously only focus on their vehicles. You can order all the different makes of OE scan tools equipped with their software and purchase their targets, and this would truly be the way to maintain your OE programs and be sure to have all the access you need to do calibrations and a great deal more that is needed to repair vehicles today.

There are aftermarket companies that do provide OE software access through their services, but they may offer targets that were made by their company, as automakers’ targets in many cases can be reproduced as long as they meet the OE specs. You could still order the OE targets through the dealer if you decide to do so and spend the time and effort to locate what you need.

There have been various challenges using these types of OE-access solutions, but, by and all, these solutions do fit many shops’ needs for services. A point I do want to address, however, is: No matter what tool or targets or information source you use to repair vehicle electronics or any safety system, you must verify that the information or access to components matches the OE service information and requirements.

In the aftermarket tool arena, there has been a lot of change initiated by a plethora of companies out there building software programs for all aspects of the repair industry. The need to service multiple vehicle lines drives the software designers to offer platforms that allow scanning, programming, reading live data and calibrating. There may always be challenges when choosing to use aftermarket products, as vehicle manufacturers keep changing their vehicles’ electronics in ways that limit access to the vehicle or specific computer modules and their functions. A scan tool’s ability to communicate with the vehicle’s components, especially in new models, has always been the crux of the issue. It takes time to catch up to all the changes and updating the aftermarket software.

Giving Credit

I’ll give a lot of credit to the aftermarket industry for building efficiencies into their scan tools and calibration equipment.

In calibration procedures, lasers have proven to be faster and more accurate in establishing vehicle center line over plumb bobs and string — as long as your batteries are charged. There will be times when technology may fail you, so never discount learning how to use a plumb bob and string that many OEM procedures still call for. Knowing how to do the process without the technology may be the difference between delivering the car on time and delivering it late.

The evolution of target stands and tripods from PVC pipe that the vehicle manufacturers use to portable stands that can hold or use multiple targets for all makes of vehicles alone has saved many shops time and effort when doing calibrations. This time savings quickly adds up to serious money for any shop. I’m amazed at how similar many companies’ target stands look, but beware: Some scan tools and how their procedures or measurements work using their particular target stand differ from OE service information. The blind spot stands and multi-use functions may be expensive, but doing your homework and buying the correct packages of targets from an aftermarket manufacturer can have a much quicker return on investment for your shop than buying what you need or don’t need individually.

Package Deals

The package deals available to shops looking to buy equipment have been a great way for them to quickly and easily get the equipment they need to finish repairs or even start repairs as far as pre-scanning the vehicle when it arrives at the shop. A disadvantage to the multiple OE scan tools available out there is that you need to have more equipment and a different tool for each vehicle make that arrives for repairs.

When doing pre-repair scans, having a tool that can scan multiple makes adds efficiency to your shop team and consistency in operations for estimating vehicles. Another advantage is that the shop only has to learn one tool as opposed to several. Let’s be honest: There is currently no scan tool that does it all for all makes and models. Learning a particular scan tool’s limitations usually involves trial and error.

Another credit to the aftermarket is that many of its scan tools use shortcut buttons to access functions and features. This helps whoever is using the tool to quickly locate the system in which a particular control module may be located. The shortcuts usually offer access to the most common service procedures a shop may need to perform.

The ease-of-use features are improving with every new version of scan tool that enters the market. Faster software speeds as well as internet connectivity improvements with more memory and functions make the new scan tools more efficient than their predecessors. Just like any computer you’ve purchased, updates can make it obsolete in a matter of months. All a shop really needs to do is make sure the scan tool is set to update regularly. This will keep all the software working at maximum efficiency. I see so many shops not do this critical step and, as a result, it doesn’t take very long before they start running into issues with their scan tools. Vehicle manufacturer updates occur all the time, so keeping up on all updates — including the dongle/VCI — is a step you can’t afford to miss.

The Next Step

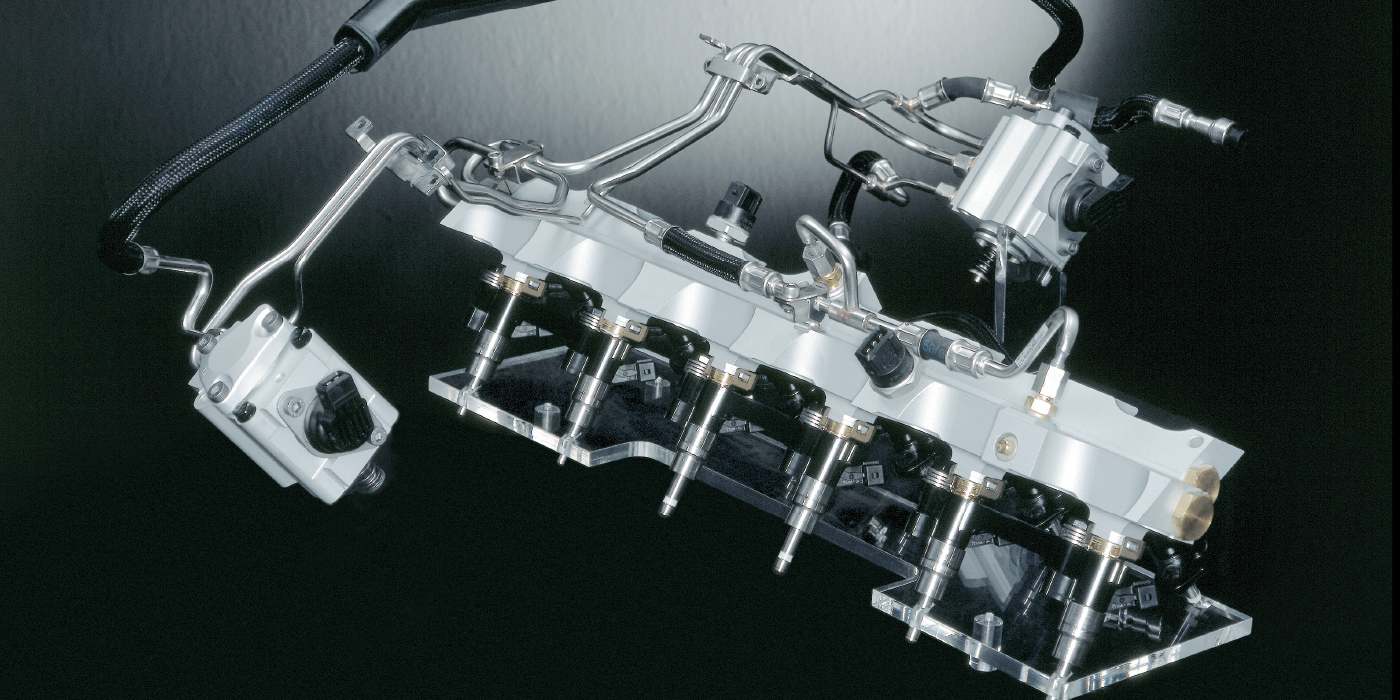

Scan tools have come a long way as far as ease of operation and ability to access the vehicle. They’ve had to evolve as the number of computers, control modules and sensors has increased.

The next step to take if you haven’t already is to learn diagnostics with the scan tools. It’s one thing to be able to clear codes and do pre- and post-repair scans and calibrations, but diagnosing when a problem occurs takes a different level of thought and training. Other tools may be needed to check connectivity and resistance in the circuits. A technician who learns to use all the features in a scan tool can program and code as well as diagnose what still needs to be repaired in the vehicle.

You bought the equipment in order to keep the vehicle in your shop for repair. Sending a vehicle out or calling someone in when you have the tools in hand doesn’t seem right — and this is largely due to lack of training available and even customer support. There are plenty of videos to help you, but it takes time to research and learn. In our impatient world, that creates a problem.

Your shop takes the time for I-CAR classes or ASE certifications, so should you be giving time to technicians to research and learn how to use all functions of the scan tools. It is time well spent.