Courtesy Body Shop Business

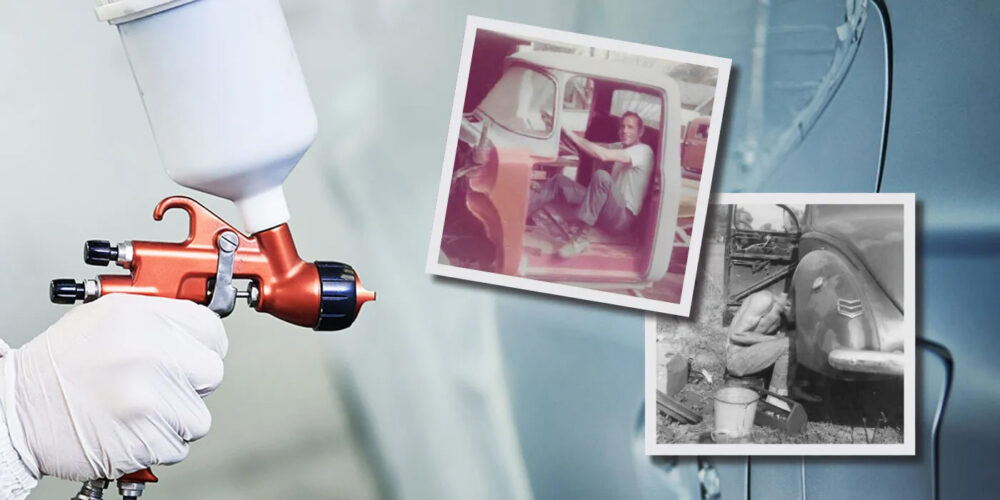

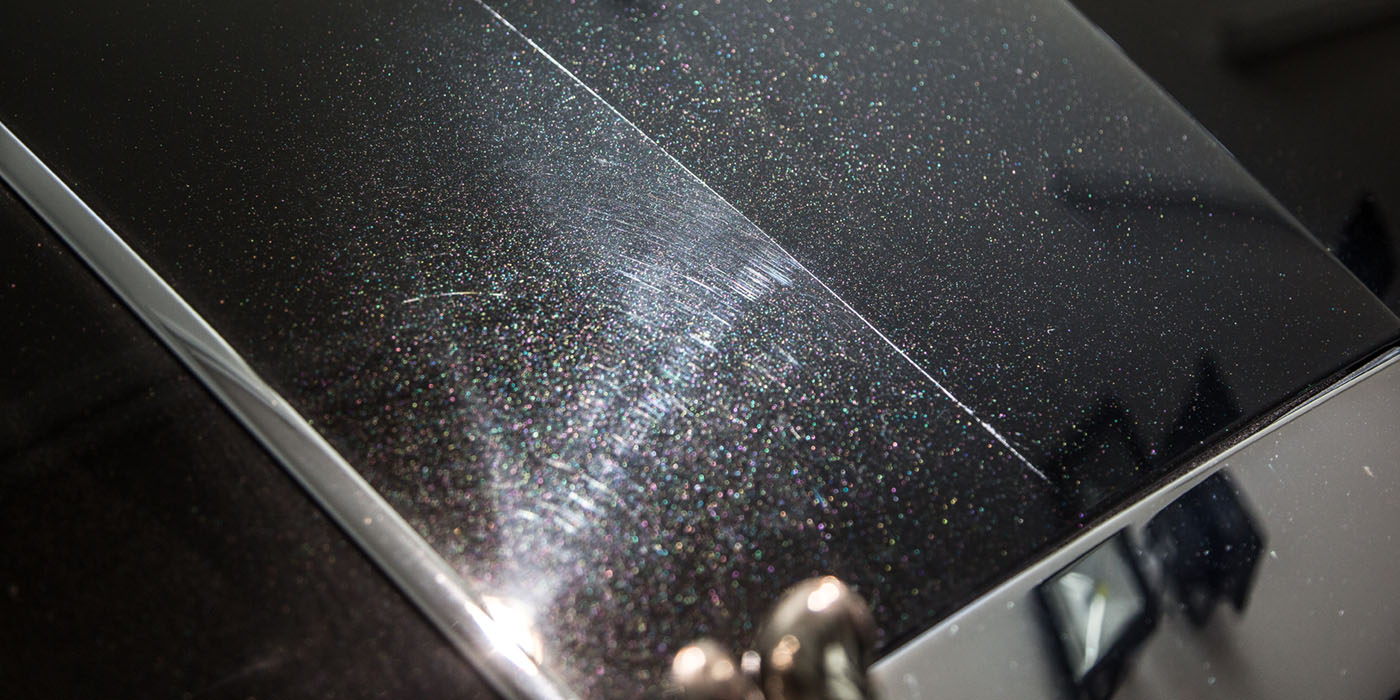

Painting and the finished product can seem quite glamorous to the youngster just getting started in the paint shop. The deep appearance of pearlescent colors swimming in high gloss clear at one time was the stuff of custom paint work by cranky, eccentric artists. Now, we regularly see these finishes on original equipment manufacturer (OEM) vehicles, and it can indeed be a challenge to replicate in the repair arena.

The prepper who can’t wait to paint does well to acknowledge that, whether a custom restoration paint job or a collision repair paint job, the foundation must be sound. You can wax or Teflon or ceramic coat for durability all you want, but if you’ve built the paint film on a suspect foundation, you cannot reasonably expect it to “look-good-long-time.”

Where It Starts

Where do we begin? As with most things in the body shop, it’s advantageous to start in the office with the estimate — which really means starting with educational training for the estimator.

about:blank

How can an estimator know that a proper repair will require an adjacent panel to be blended — or stripped — prior to refinishing? Years of experience will be helpful, as will having the painter assist with an audit of the estimate. A paint film mil-gauge will reveal a film build past its recommended thickness. A little solvent on a rag rubbed in an inconspicuous area will tell us if the existing coating is reversable (think lacquer). Paint film builds have limits and must be stripped when exceeded, and I know of no paint manufacturer who does not recommend removing reversible coatings when present. The point here is to identify as much as possible upfront to enable the job to flow without delay.

It’s now common knowledge that every time a supplement is generated for additional parts or labor, the job stalls out, and administratively there is a cost associated with the additional parts processing. We’re getting pretty good at 100% disassembly with a complete parts order in mind, but I’d suggest we still have room for improvement on the paint-labor portion of the estimate. I believe every paint manufacturer has estimative tutorial resources available on its website. Let us at least ask to be paid for what we must do to ensure a proper refinish repair. Now, to the shop!